Brushless DC (BLDC) motors are becoming increasingly popular in various applications due to their efficiency, reliability, and performance. This comprehensive article will explore BLDC motor controllers, their working principles, circuit diagrams, control algorithms, and more, providing a detailed understanding of their role in modern motor control systems.

What is a BLDC Motor Controller?

A BLDC motor controller is an electronic device that manages the operation of a BLDC motor. It regulates the speed, direction, and torque of the motor by controlling the current and voltage applied to the motor windings. The controller ensures efficient and smooth operation, making BLDC motors ideal for applications in automotive, industrial, and consumer electronics.

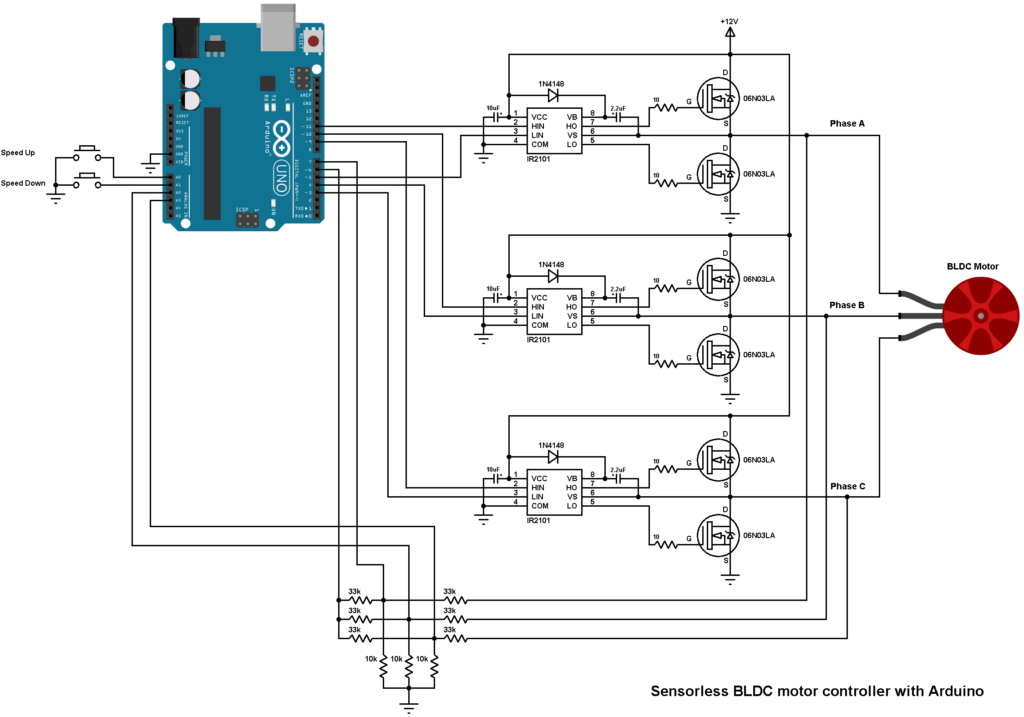

BLDC Motor Controller Circuit Diagram

The circuit diagram of a BLDC motor controller typically includes the following components:

Microcontroller

Acts as the brain of the controller, executing control algorithms and processing sensor inputs.

Gate Drivers

Interface between the microcontroller and power transistors, ensuring proper switching.

Power Transistors (MOSFETs or IGBTs)

Switch the current through the motor windings.

Hall Sensors or Encoders

Provide rotor position feedback to the controller.

Current Sensors

Monitor the current flowing through the motor phases.

Power Supply

Provides the necessary voltage and current for the controller and motor.

3 Phase BLDC Motor Controller

A 3-phase BLDC motor controller is designed to control motors with three windings. The controller uses a combination of pulse-width modulation (PWM) and commutation logic to switch the power transistors, ensuring that the correct phase currents are applied to the motor windings. This method provides precise control over the motor’s speed and torque.

The following diagram illustrates a basic BLDC motor controller circuit using a Micrcontroller:

BLDC Motor Control Algorithm

The control algorithm is a crucial aspect of BLDC motor controllers. It determines how the controller responds to various inputs, such as speed commands and rotor position. The most common control algorithms include:

Six-Step Commutation

In six-step commutation, also known as trapezoidal commutation, the controller energizes two of the three motor phases at a time, creating a rotating magnetic field. This method is simple and efficient but can produce torque ripple at low speeds.

Field-Oriented Control (FOC)

Field-Oriented Control (FOC) is an advanced control algorithm that provides smooth and precise control of BLDC motors. It uses mathematical transformations to decouple the motor’s torque and flux components, allowing independent control of each. FOC offers superior performance, especially in applications requiring high precision and dynamic response.

How to Make a BLDC Motor Controller

Designing a BLDC motor controller involves several steps:

Select the Microcontroller

Choose a microcontroller with sufficient processing power and I/O capabilities.

Design the Power Stage

Select appropriate power transistors, gate drivers, and current sensors.

Develop the Control Algorithm

Implement the control algorithm in the microcontroller firmware.

Design the PCB

Create a printed circuit board (PCB) layout for the controller.

Test and Debug

Thoroughly test the controller with the motor and refine the design as needed.

How Does a BLDC Motor Controller Work?

A BLDC motor controller works by:

Receiving Input Commands

The controller receives speed and direction commands from an external source.

Sensing Rotor Position

Hall sensors or encoders provide feedback on the rotor’s position.

Executing Control Algorithm

The microcontroller processes the input commands and sensor data to determine the appropriate switching signals for the power transistors.

Driving the Motor

The power transistors apply the correct phase currents to the motor windings, generating the desired torque and speed.

BLDC Motor Controller Board

A BLDC motor controller board is a printed circuit board (PCB) that houses all the necessary components for controlling a BLDC motor. It typically includes the microcontroller, gate drivers, power transistors, sensors, and connectors for interfacing with the motor and external systems. Commercially available BLDC motor controller boards simplify the process of integrating BLDC motors into various applications.

What is the Difference Between BLDC and PMSM Controllers?

While both BLDC (Brushless DC) and PMSM (Permanent Magnet Synchronous Motor) controllers are used to control motors with permanent magnets, they differ in their control methods:

BLDC Controller

Typically uses trapezoidal commutation (six-step) and is simpler and less costly.

PMSM Controller

Uses sinusoidal commutation or Field-Oriented Control (FOC), providing smoother operation and higher efficiency, especially at low speeds.

Are BLDC Motors Good or Bad?

BLDC motors are generally considered good due to their high efficiency, reliability, and performance. They have several advantages, including:

High Efficiency

Reduced energy losses compared to brushed motors.

Long Lifespan

No brushes to wear out, resulting in longer operational life.

Low Maintenance

Fewer mechanical parts reduce the need for regular maintenance.

However, BLDC motors can be more expensive and complex to control compared to brushed motors.

What is the Best Way to Control a BLDC Motor?

The best way to control a BLDC motor depends on the application requirements. For high-performance applications, Field-Oriented Control (FOC) is often the best choice due to its precision and smooth operation. For simpler applications, six-step commutation may be sufficient and more cost-effective.

What are the Problems on BLDC Motor?

While BLDC motors offer many benefits, they can have some problems:

Complexity

The control system is more complex than for brushed motors.

Cost

BLDC motors and controllers can be more expensive.

Noise Sensitivity

The sensors and control algorithms can be sensitive to electrical noise, affecting performance.

Is a BLDC Motor AC or DC?

A BLDC motor is technically a DC motor but operates using an AC waveform generated by the controller. The motor windings are driven by DC power, but the controller creates a three-phase AC signal to drive the motor.

How Efficient is BLDC Motor Controller?

BLDC motor controllers are highly efficient, often achieving efficiencies of 85-95%. The efficiency depends on factors such as the quality of components, design of the controller, and the control algorithm used.

What is the Life Expectancy of a BLDC Motor?

The life expectancy of a BLDC motor is typically 10,000 to 30,000 hours, depending on the operating conditions and quality of the motor. The absence of brushes eliminates wear and tear, significantly extending the motor’s lifespan.

How Long Can a BLDC Motor Run Continuously?

A BLDC motor can run continuously for extended periods, provided it operates within its rated parameters. Proper thermal management and adequate cooling are essential to prevent overheating and ensure long-term reliability.

Why is BLDC So Expensive?

BLDC motors are more expensive than brushed motors due to several factors:

Complex Manufacturing

The manufacturing process is more intricate, involving precise placement of magnets and windings.

Advanced Electronics

The need for sophisticated electronic controllers adds to the cost.

High-Quality Components

BLDC motors use high-quality materials and components to achieve high efficiency and reliability.

Arshon Technology: Leading in BLDC Motor Controller Innovation

Arshon Technology is a pioneer in the development of advanced BLDC motor controllers, providing innovative solutions for a wide range of applications. With a focus on cutting-edge technology and superior performance, Arshon Technology designs and manufactures high-quality BLDC motor controllers that meet the highest standards of efficiency, reliability, and precision. Their expertise in control algorithms and system integration ensures that their clients receive state-of-the-art solutions tailored to their specific needs. As a leader in the field, Arshon Technology continues to push the boundaries of what is possible with BLDC motor controllers, driving the future of motor control technology.

Conclusion

BLDC motor controllers are essential for the efficient and reliable operation of brushless DC motors, offering numerous advantages over traditional brushed motors. Understanding the principles, components, and control algorithms of BLDC motor controllers is crucial for leveraging their full potential in various applications. With advancements in technology and increasing demand for high-performance motor control solutions, BLDC motor controllers will continue to play a vital role in modern industries. Leading companies like Arshon Technology are at the forefront of this innovation, providing cutting-edge BLDC motor controllers that set new standards in the industry.