In today’s fast-paced world, ensuring the reliability and durability of electronic products is paramount. From consumer electronics to industrial systems, products must withstand real-world stresses over their intended operational lifetime. This is where the Accelerated Lifetime Test (ALT) comes into play. ALT test simulates years of operational stress in a matter of weeks, providing manufacturers with a predictive analysis of how their products will perform over time.

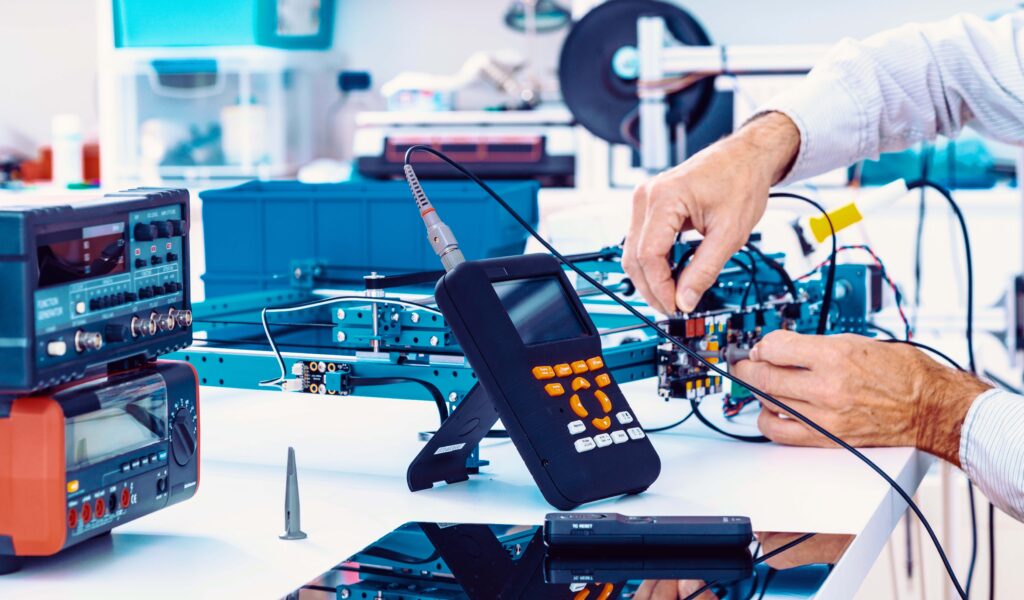

Arshon Technology, a leader in electronic design and prototyping, implements ALT tests for products developed in-house, delivering comprehensive insights through detailed reports. This article explores what ALT is, its methodology, benefits, and how it helps ensure product reliability.

What is ALT (Accelerated Lifetime Test)?

The Accelerated Lifetime Test (ALT) is a testing process used primarily for electronic products. It subjects the device or component to accelerated environmental conditions, such as extreme temperature, humidity, mechanical stress, and vibration, simulating years of operation within a much shorter period—typically 20 to 30 days. This allows manufacturers to identify potential failures and weaknesses in their designs before releasing the product to market.

The goal of ALT test is to:

– Simulate long-term wear and tear on a product within a compressed time frame.

– Identify design or manufacturing flaws that might not appear under normal testing conditions.

– Ensure that products meet the required durability and reliability standards.

For instance, ALT can help determine whether an electronic circuit board will last for over ten years in real-world operating conditions, without waiting a decade to find out. The test can identify weak components, poor soldering connections, or failures under mechanical stress that could compromise the product’s integrity over time.

Key Elements of the ALT Process

ALT involves several key factors that stress a product in a controlled environment to replicate years of use. The tests are conducted using specialized environmental chambers where various stressors are applied.

1. Temperature Cycling

Temperature changes play a significant role in ALT. Products undergo temperature cycling, where the temperature fluctuates between extreme highs and lows to simulate real-world temperature variations over time.

– High temperatures can induce thermal expansion, which stresses the electronic components.

– Low temperatures cause contraction, which can lead to material fatigue.

At Arshon Technology, typical ALT testing cycles products between extreme temperatures every 8 hours for 20 to 30 days. This cycle mimics the repeated thermal stresses that an electronic product might experience over a decade.

2. Humidity Stress

Humidity levels are also varied in conjunction with temperature fluctuations. High humidity levels can lead to condensation, which poses a risk of corrosion in electronic circuits and boards. Low humidity can exacerbate electrostatic discharge risks, potentially damaging sensitive components.

By simulating these conditions, ALT helps ensure that electronic products can operate reliably in environments ranging from arid deserts to humid tropics.

3. Mechanical Shock and Vibration

In addition to environmental stressors, many companies incorporate mechanical shock and vibration into their ALT protocols. These simulate physical forces such as drops, bumps, or constant vibrations that a product may endure during transportation, installation, or day-to-day use.

– Shock testing replicates sudden jolts or impacts that may occur in the field.

– Vibration testing simulates the low-frequency vibrations that products may experience, such as during transportation or when installed in vehicles.

Arshon Technology integrates both vibration and mechanical shock elements in its ALT testing, particularly for products that may be subject to physical stresses during their lifespan, such as automotive or industrial control systems.

Lack of Standardization in ALT Testing

One of the most interesting aspects of ALT is the absence of a standard, industry-wide testing procedure. Instead, companies develop custom ALT protocols tailored to their specific products and the environments in which they will operate.

At Arshon Technology, the ALT process is customized for each product based on its unique specifications and use cases. This may involve combining multiple environmental stressors, such as high humidity with vibration, or adjusting the test durations and intervals.

Companies often create their own home-made test procedures, as no singular method fits all products. For example, an electronic board used in harsh industrial environments will require different stress testing compared to a consumer gadget used indoors.

Examples of Customized ALT Testing:

– Telecommunications Equipment:

ALT might simulate continuous operation with temperature and humidity cycling, ensuring components like capacitors, resistors, and ICs perform reliably over a decade.

– Automotive Electronics:

These tests may include high-frequency vibration and thermal cycling to replicate the heat and movement experienced in vehicles over many years.

Advantages of ALT Testing

Implementing ALT in product development and validation offers a number of important benefits:

1. Early Failure Detection

ALT helps manufacturers detect potential failures early in the design phase, allowing them to make necessary adjustments before the product hits the market.

2. Cost Savings

Identifying and correcting issues before full-scale production saves costs associated with recalls, warranty claims, and repairs. By ensuring reliability up front, ALT can significantly reduce the overall cost of quality management.

3. Increased Product Reliability

Products that pass ALT are more likely to operate reliably throughout their intended lifespan. This ensures customer satisfaction, reduces field failures, and enhances the manufacturer’s reputation for quality.

4. Market Competitiveness

ALT provides a competitive edge by ensuring that products meet or exceed industry standards for durability and reliability. Consumers are more likely to choose products with proven longevity.

ALT Test at Arshon Technology

At Arshon Technology, ALT is an integral part of the product validation process. The company has developed customized ALT protocols to simulate the exact operating environments their clients’ products will face.

The ALT Procedure at Arshon Technology:

1. Environmental Chamber Setup:

The product is placed inside a chamber where the temperature and humidity are controlled and cycled.

2. Temperature Cycling:

Every 8 hours, the temperature cycles between extreme highs and lows to induce stress on the product’s components.

3. Humidity Variation:

Simultaneously, humidity levels are adjusted to mimic real-world environmental conditions.

4. Mechanical Stress:

Depending on the product’s application, mechanical shock and vibration may be added to further stress the product.

5. Performance Monitoring:

Throughout the test, the product’s performance is continuously monitored to detect any signs of degradation or failure.

6. Comprehensive Reporting:

Once the test is complete, a detailed report is generated. This report outlines how the product performed under stress, identifying any weaknesses or areas for improvement.

By incorporating ALT testing into the design and development process, Arshon Technology ensures that the products they create are reliable, durable, and ready for long-term use in even the most challenging environments.

Conclusion

The Accelerated Lifetime Test (ALT) is a crucial tool for ensuring the longevity and reliability of electronic products. By simulating years of wear and tear in just a few weeks, ALT helps manufacturers identify and address potential failures before products are released into the market.

Arshon Technology’s implementation of ALT testing ensures that their clients’ products meet the highest standards of quality and reliability, backed by comprehensive reporting. Whether dealing with temperature extremes, humidity variations, or mechanical stress, Arshon’s products are designed and tested to withstand the challenges of real-world operation.

By incorporating ALT into your product development process, you can ensure that your electronics are built to last, giving you confidence in their performance for years to come.