Introduction

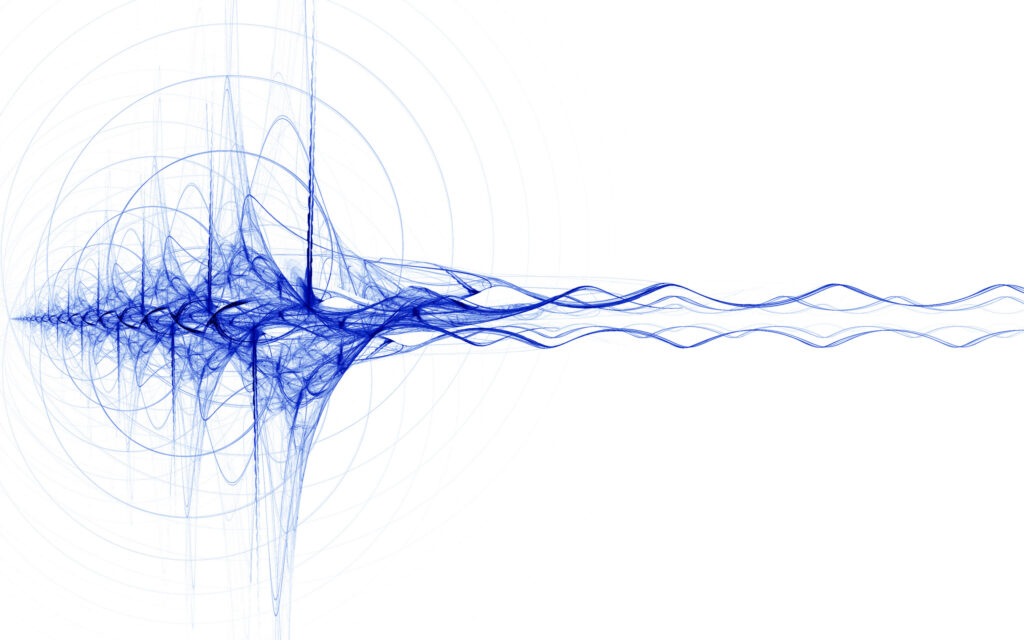

Structural health monitoring (SHM) is critical for ensuring the safety and reliability of engineering structures like bridges, buildings, dams, and aircraft. One of the most effective ways to detect defects in these structures is by monitoring their vibration modes. Vibration-based monitoring capitalizes on the fact that a structure’s dynamic behavior changes when it develops defects such as cracks, material degradation, or loosened joints. These changes manifest as variations in the structure’s natural frequencies, mode shapes, and damping ratios.

This article will explore how vibration monitoring using Predictive Maintenance techniques can detect structural defects, the methodologies used, and the real-world applications of these techniques in industries such as construction, aerospace, and transportation.

Vibration Modes and Their Importance in Pdm

Vibration modes refer to the characteristic ways a structure oscillates when subjected to an external force or disturbance. Every structure has a set of natural frequencies, which depend on its geometry, material properties, boundary conditions, and loading conditions. These natural frequencies correspond to different mode shapes—specific patterns in which different parts of the structure move during vibration.

How Defects Alter Vibration Modes

When a structure experiences damage, its mass, stiffness, and damping properties are affected. A crack, for instance, reduces the stiffness of a material, which in turn alters the structure’s natural frequency. The following changes occur as a result:

– Reduction in stiffness leads to a decrease in natural frequency.

– Changes in mass distribution can shift vibration patterns.

– Localized defects such as cracks affect the mode shapes, leading to distortions in the way the structure vibrates.

Monitoring these changes provides critical insights into the condition of the structure. By comparing the vibration characteristics of a healthy structure to its current state, defects can be detected early, potentially preventing catastrophic failure.

Vibration Monitoring Techniques for early Defect Detection

There are several techniques used to detect structural defects through vibration monitoring at an earlier stage. These methods can be broadly categorized into experimental techniques that measure the structure’s vibrations and analytical methods used to interpret the data. Every case may different based on the size and mechanical features of the structure, but over all, vibration monitoring is the heart of the Predictive Maintenance.

1. Baseline Measurements

The first step in detecting structural defects is to establish baseline measurements for the structure in its undamaged state. This involves:

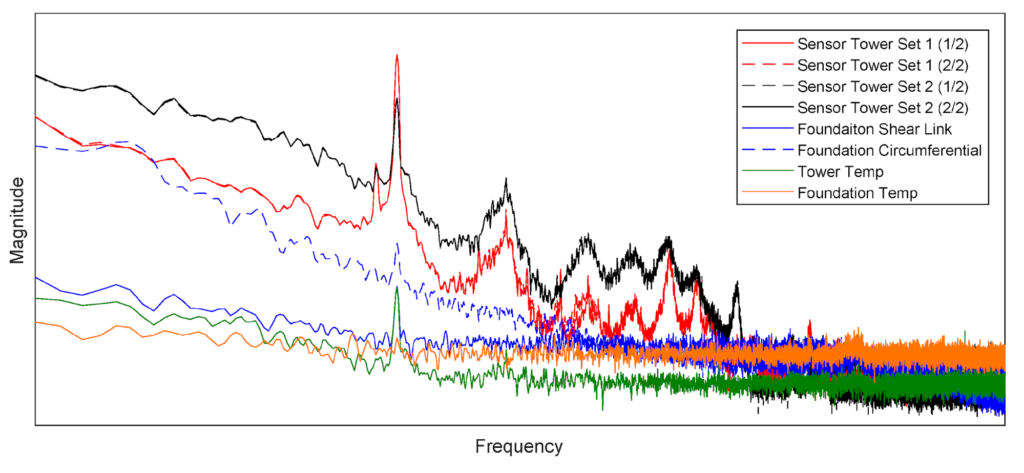

– Attaching sensors (e.g., accelerometers, strain gauges, or laser Doppler vibrometers) at various points on the structure.

– Measuring the structure’s natural frequencies, mode shapes, and damping ratios under different loading conditions.

– Creating a frequency response curve through techniques like Fast Fourier Transform (FFT) to analyze the structure’s vibration characteristics.

This baseline data is crucial because it serves as a reference point for future comparisons. Any significant deviation from these measurements can indicate the presence of a defect.

2. Forced Vibration Testing

In forced vibration testing, an external force is applied to the structure, often through devices like shakers or impact hammers. The resulting vibrations are recorded, and the frequency response function (FRF) is derived. Changes in the FRF indicate alterations in the structure’s natural frequencies and mode shapes, suggesting potential damage.

This method is highly effective in controlled environments and is often used in laboratories or for large structures where ambient vibrations alone may not provide enough data.

3. Operational Modal Analysis (OMA)

In some cases, it may not be feasible to apply external forces to a structure. Operational Modal Analysis measures the structure’s vibration during normal operation, using ambient excitations like wind, traffic, or machinery vibrations. This technique is particularly useful for bridges, high-rise buildings, or aircraft, where forced testing may be impractical.

OMA captures the structure’s vibration characteristics under real-world conditions and helps detect anomalies in the natural frequencies and mode shapes over time.

Defect Detection through Frequency and Mode Shape Changes

a) Frequency Shifts

Damage in a structure often manifests as a reduction in natural frequencies. For example, in a steel bridge, the formation of a crack reduces the stiffness of the bridge at that point, causing its natural frequency to drop. By monitoring these frequency shifts, engineers can detect the existence of defects.

One way to quantify this change is through Frequency Response Analysis (FRA). A sharp reduction in frequency can indicate a defect, while smaller shifts may require further investigation. The relationship between stiffness and frequency is inversely proportional: as stiffness decreases, frequency lowers, signaling potential damage.

b) Mode Shape Changes

While frequency shifts provide an initial indication of damage, mode shape analysis is often used to localize the defect. Changes in mode shapes are particularly helpful in identifying where the damage has occurred.

For example, a mode shape corresponding to a specific frequency in a healthy structure might show uniform vibration across its length. When damage occurs, however, this uniformity is disrupted. Areas near the damage vibrate differently than undamaged regions.

Advanced techniques like Modal Assurance Criterion (MAC) allow engineers to compare the mode shapes of a healthy structure with those of a potentially damaged one. By calculating the correlation between the two, engineers can pinpoint areas of the structure where damage has occurred.

Defect Localization Techniques

Once the presence of a defect has been detected, the next challenge is localizing it. Several methods can help identify where the damage is located within a structure:

a) Damage Index Method

The damage index method compares the natural frequencies or mode shapes of a damaged structure to those of a healthy one. The damage index quantifies changes in the structure’s dynamic behavior. A high damage index indicates areas where the structure’s properties have been significantly altered, helping to localize the defect.

b) Frequency Domain Decomposition (FDD)

Frequency Domain Decomposition is an advanced technique that decomposes vibration data into different frequency components. By analyzing how these components change over time, engineers can identify localized defects. FDD is highly effective in detecting small or localized damage that may not produce significant changes in overall frequency.

c) Modal Strain Energy (MSE) Method

The Modal Strain Energy method calculates the strain energy in different parts of the structure. Damage typically increases the strain energy in the affected region, allowing engineers to localize the defect. This method is especially useful for complex structures like aircraft wings or high-rise buildings.

Machine Learning and AI for Vibration-Based Defect Detection

With the advent of machine learning and artificial intelligence (AI), vibration-based defect detection has become even more sophisticated. By training machine learning models on large datasets of vibration signals, it’s possible to automate defect detection and localization.

a) Neural Networks

Neural networks can be trained to recognize patterns in vibration data that indicate defects. For example, by feeding the network vibration data from both healthy and damaged structures, it can learn to identify subtle changes in natural frequencies and mode shapes that signal the presence of defects.

b) Support Vector Machines (SVM)

SVMs are another powerful machine learning tool for detecting structural defects. By analyzing the frequency response functions (FRF) and other vibration features, an SVM model can classify the structure as either healthy or damaged.

Challenges in Vibration-Based Defect Detection

Despite its effectiveness, vibration-based defect detection comes with challenges. Some of the most common include:

– Environmental factors:

Temperature, humidity, and other environmental factors can affect the structure’s vibration response, making it difficult to distinguish between real defects and environmental changes.

– Small or localized defects:

Small cracks or defects may cause only minor changes in vibration modes, requiring highly sensitive equipment for detection.

– Complex structures:

For structures with complex geometries or material compositions, interpreting vibration data can be challenging.

Real-World Applications

Vibration monitoring has been successfully implemented in several real-world applications:

– Bridges and Infrastructure:

Many bridges are equipped with vibration monitoring systems to detect damage from wear and tear or external events like earthquakes.

– Aircraft and Aerospace:

Vibration monitoring is critical in the aerospace industry for detecting fatigue in aircraft components.

– Buildings and Towers:

High-rise buildings use vibration monitoring to detect structural degradation over time.

Conclusion

Monitoring vibration modes is an effective and reliable method for detecting structural defects. By analyzing changes in natural frequencies, mode shapes, and damping ratios, engineers can identify and localize damage before it leads to catastrophic failure. With the integration of AI and machine learning, vibration-based defect detection is becoming even more powerful, offering real-time monitoring and early warning systems across various industries.