In an era defined by rapid technological advancements and digital transformation, industries are increasingly leveraging Artificial Intelligence (AI) to improve their operational efficiencies. One significant application of AI in industrial settings is predictive maintenance, particularly concerning electrical equipment. As manufacturers strive to minimize downtime, reduce maintenance costs, and extend the lifespan of their assets, predictive maintenance emerges as a revolutionary approach powered by AI. This article delves deep into the role of AI in predictive maintenance for electrical equipment, addressing its importance, functionalities, benefits, challenges, and future prospects.

Understanding Predictive Maintenance

What is Predictive Maintenance?

Predictive maintenance refers to the proactive approach of using data analysis, AI, and machine learning to predict equipment failures before they occur. By analyzing historical data, performance metrics, and real-time monitoring, organizations can schedule maintenance activities only, when necessary, rather than following a predetermined schedule or reacting to equipment failures.

The Shift from Reactive to Predictive Maintenance

Historically, organizations relied on reactive maintenance—repairing equipment only after it failed. This approach often led to unplanned downtime, lost productivity, and increased costs. Over time, the industry transitioned to preventive maintenance, where regular maintenance checks are scheduled based on time intervals. However, these methods didn’t address the real cause of failures or optimize resource allocation.

The adoption of predictive maintenance powered by AI represents a significant leap forward. Predictive maintenance combines real-time data with advanced algorithms to foresee potential issues, allowing for timely interventions that minimize disruption and maximize operational efficiency.

The Role of AI in Predictive Maintenance

Data Collection and Integration

At the core of predictive maintenance is data. Electrical equipment in industrial settings produces vast amounts of data from various sources, including sensors, control systems, and operational logs. AI technologies assist in aggregating, cleaning, and integrating this data from disparate systems to provide a comprehensive view of equipment performance.

AI can handle both structured data (like operational metrics) and unstructured data (like maintenance logs and sensory inputs). This holistic data collection allows for a better understanding of equipment health and performance, setting the foundation for predictive models.

Machine Learning and Data Analysis

Once the data is collected, machine learning algorithms come into play. These algorithms analyze historical data to identify patterns and correlations that might indicate impending failures.

Key Techniques in Machine Learning for Predictive Maintenance:

Anomaly Detection:

AI systems can identify deviations from normal operating conditions, helping to detect early signs of malfunction.

Regression Techniques:

By using regression analysis, AI can quantify the relationships between different operational parameters, allowing for the prediction of equipment lifespan.

Time Series Analysis:

Many parameters in electrical equipment operate over time, making time series analysis crucial to predict future values based on historical data trends.

Deep Learning:

Advanced neural networks can analyze complex datasets with multiple variables, enhancing prediction accuracy.

Natural Language Processing (NLP):

NLP can analyze textual data, such as maintenance logs and reports, to extract insights and issues that may not be evident in structured data alone.

Predictive Algorithms and Models

Once the data is processed, predictive algorithms are employed to create models tailored to specific equipment. These models can forecast when an electrical component is likely to fail or require maintenance, enabling organizations to plan interventions strategically.

AI tools can incorporate various parameters, such as operating temperature, load conditions, and vibration patterns, to generate more reliable predictions. Over time, the models improve as they learn from new data, constantly refining their accuracy.

Real-Time Monitoring and Alerts

In the landscape of predictive maintenance, real-time monitoring is crucial. AI systems enable continuous surveillance of electrical equipment, employing IoT devices and sensors that feed data back to central systems.

When AI detects anomalies or predicts a potential failure, it can instantly send alerts to maintenance teams, allowing them to act before a significant problem occurs. This real-time capability reduces the risk of catastrophic failures and minimizes operational downtime.

Benefits of AI in Predictive Maintenance

The integration of AI into predictive maintenance brings numerous benefits to industrial settings:

Reduced Operational Downtime

By predicting failures ahead of time, AI-equipped predictive maintenance systems drastically reduce unplanned downtime. This leads to smoother production processes and improved workflow.

Cost Savings

Predictive maintenance reduces costs associated with emergency repairs, redundant maintenance tasks, and equipment replacement. Organizations spend less on needless interventions and can allocate budgets toward more strategic initiatives.

Extended Equipment Lifespan

Regular maintenance is essential for prolonging equipment life. Predictive maintenance ensures that maintenance is conducted at the optimal time, allowing machinery to operate efficiently and last longer.

Enhanced Safety and Compliance

Predictive maintenance aids in identifying potential safety issues before they become critical. This proactive management not only protects employees and operators but also ensures compliance with industry regulations.

Improved Resource Allocation

With predictive maintenance insights, organizations can optimize their maintenance schedules and manpower allocation. Instead of deploying technicians for routine checks, they can focus on areas needing immediate attention.

Enhanced Performance Insights

AI-powered predictive maintenance generates rich data insights that help organizations analyze overall equipment effectiveness (OEE) and spot trends that may lead to performance improvements.

Challenges of Implementing AI in Predictive Maintenance

Despite the myriad benefits of AI-driven predictive maintenance, organizations face several challenges during implementation:

Data Quality and Availability

The accuracy of predictive maintenance heavily relies on the quality and completeness of data. Poor data quality may lead to erroneous predictions, undermining the entire initiative.

System Integration

Integrating AI predictive maintenance solutions with existing systems can be complex. Many organizations have legacy systems that aren’t compatible with modern AI technologies, necessitating additional investments.

Skill Gap

There’s a shortage of professionals with the requisite skills to implement, manage, and optimize AI-driven predictive maintenance systems. Investing in training and hiring can be costly and time-consuming.

Resistance to Change

Organizations may face resistance from employees who are accustomed to traditional maintenance methods. Educational initiatives are essential to overcome skepticism and promote acceptance of AI technologies.

Data Privacy and Security

With the increased use of IoT devices and data connectivity, concerns regarding data privacy and cybersecurity become paramount. Organizations must ensure that their data processing systems are secure from potential breaches.

Future Prospects

The future of AI in predictive maintenance for electrical equipment looks promising as organizations continue to innovate and adapt to new technologies.

Enhanced AI Technologies

Advancements in AI technologies, including improved algorithms and machine learning models, promise to enhance the predictive maintenance landscape even further. These developments will lead to even more accurate predictions and faster response times.

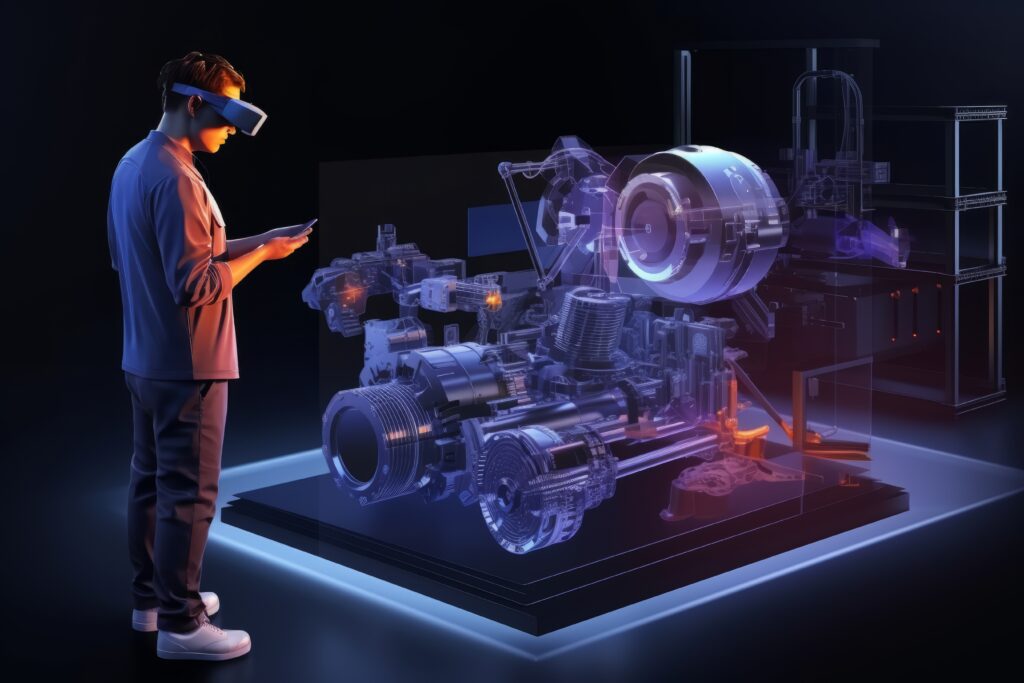

Integration of AI with Augmented Reality (AR)

Augmented reality can augment predictive maintenance by providing technicians with real-time data and insights during repairs or inspections. This combination can lead to more informed decision-making.

Collaborative Robotics

Collaborative robots (cobots) may play a role in predictive maintenance by helping human technicians with tasks such as monitoring equipment or conducting inspections.

Digital Twins

The concept of digital twins—virtual models of physical systems—can become integral to predictive maintenance. By simulating equipment performance, organizations can test different scenarios and maintenance strategies in a risk-free environment.

Real-time Data Sharing

As organizations transition to cloud computing, real-time data sharing among different teams can streamline decision-making, enhance collaboration, and enable collective insights about equipment health.

The Impact of Arshon Technology on Modern Industries

Arshon Technology is a leader in predictive maintenance, utilizing cutting-edge AI algorithms and machine learning techniques to create tailored solutions for electrical equipment across a variety of industrial sectors. Their expertise includes real-time data analytics, thorough performance monitoring, and an easy-to-navigate dashboard that provides insights into equipment health. By utilizing IoT sensors, Arshon Technolog’s predictive maintenance solutions can detect potential failures before they happen and offer actionable recommendations, enabling organizations to optimize their maintenance schedules. Furthermore, Arshon emphasizes user-friendly interfaces to ensure that teams can easily adopt the system and fully utilize its capabilities, facilitating a smooth transition from reactive to predictive maintenance approaches.

Conclusion

The role of AI in predictive maintenance for electrical equipment in industrial settings cannot be overstated. It not only provides a pathway to optimize equipment performance and reliability but also revolutionizes maintenance paradigms in various industries. While challenges persist, the benefits of AI-powered predictive maintenance—from reduced downtime and costs to enhanced safety and operational efficiency—underscore its value in modern industrial practices. As technological advancements continue, the future of predictive maintenance will likely be characterized by even more sophisticated AI applications, positioning organizations on the cutting edge of innovation and performance. Embracing these changes will empower industries to not only survive but thrive in the competitive landscape.