The petrochemical industry is one of the most critical sectors for global energy production, providing the raw materials for plastics, chemicals, and fuels. However, the complexity and scale of operations in this sector present unique challenges, especially in maintaining the reliability of equipment that operates in harsh and high-pressure environments. Unexpected downtime due to equipment failure can result in significant financial losses, environmental hazards, and production bottlenecks.

Predictive maintenance, powered by smart sensors and advanced analytics, has emerged as a game-changing solution for reducing downtime and improving operational efficiency. By continuously monitoring equipment health and predicting failures before they occur, petrochemical companies can avoid costly shutdowns, ensure safety, and optimize resource allocation.

The Importance of Maintenance in the Petrochemical Industry

The petrochemical industry relies on highly specialized and expensive equipment, including pumps, compressors, reactors, distillation columns, and heat exchangers. These machines are subjected to extreme temperatures, pressures, and corrosive chemicals, which can lead to wear and tear over time. Traditional maintenance approaches, such as reactive maintenance (fixing equipment after it fails) or scheduled maintenance (performing maintenance at regular intervals), have several drawbacks.

Reactive maintenance can lead to unplanned outages, resulting in significant production losses, safety risks, and even environmental hazards, such as leaks or spills of hazardous materials. On the other hand, scheduled maintenance can be inefficient, as it often involves servicing equipment that may not require immediate attention, leading to unnecessary downtime and costs.

Predictive maintenance offers a more efficient approach by allowing companies to maintain equipment based on actual performance data. Smart sensors continuously monitor critical parameters, such as vibration, temperature, pressure, and flow rates, detecting early signs of potential failure. By analyzing this data, companies can predict when equipment is likely to fail, allowing them to perform maintenance only when necessary, thus reducing unplanned downtime and optimizing maintenance schedules.

How Smart Sensors Enable Predictive Maintenance

Smart sensors are at the heart of predictive maintenance systems. These sensors collect real-time data on equipment performance, providing insights into the condition of machinery. In the petrochemical industry, smart sensors are used in various critical systems, including pumps, compressors, valves, and rotating equipment. The data collected by these sensors is fed into advanced analytics platforms, where machine learning algorithms analyze it to detect patterns and predict potential failures.

1. Vibration Monitoring

Vibration is one of the most common indicators of mechanical failure. Abnormal vibrations in rotating equipment, such as pumps and compressors, can signal issues like misalignment, bearing wear, or imbalance. Smart vibration sensors can detect even minor deviations in vibration levels, allowing maintenance teams to address problems before they lead to catastrophic failure.

For example, in a refinery, vibration sensors installed on centrifugal pumps can monitor the condition of the bearings and shaft alignment. If the vibration levels exceed predetermined thresholds, the system sends an alert to the maintenance team, enabling them to schedule repairs before the pump fails and causes a production halt.

2. Temperature and Pressure Monitoring

Temperature and pressure are critical parameters in petrochemical processes, where fluctuations can lead to equipment failure or safety hazards. Smart temperature and pressure sensors provide real-time data on equipment performance, ensuring that machines operate within safe limits. Any deviations from normal operating conditions are immediately detected, allowing for timely interventions.

For instance, in a heat exchanger, temperature sensors can detect overheating due to fouling or blockage, which could reduce efficiency and lead to equipment failure. By identifying these issues early, operators can clean or repair the heat exchanger, avoiding unscheduled shutdowns and prolonging the life of the equipment.

3. Flow Rate and Valve Monitoring

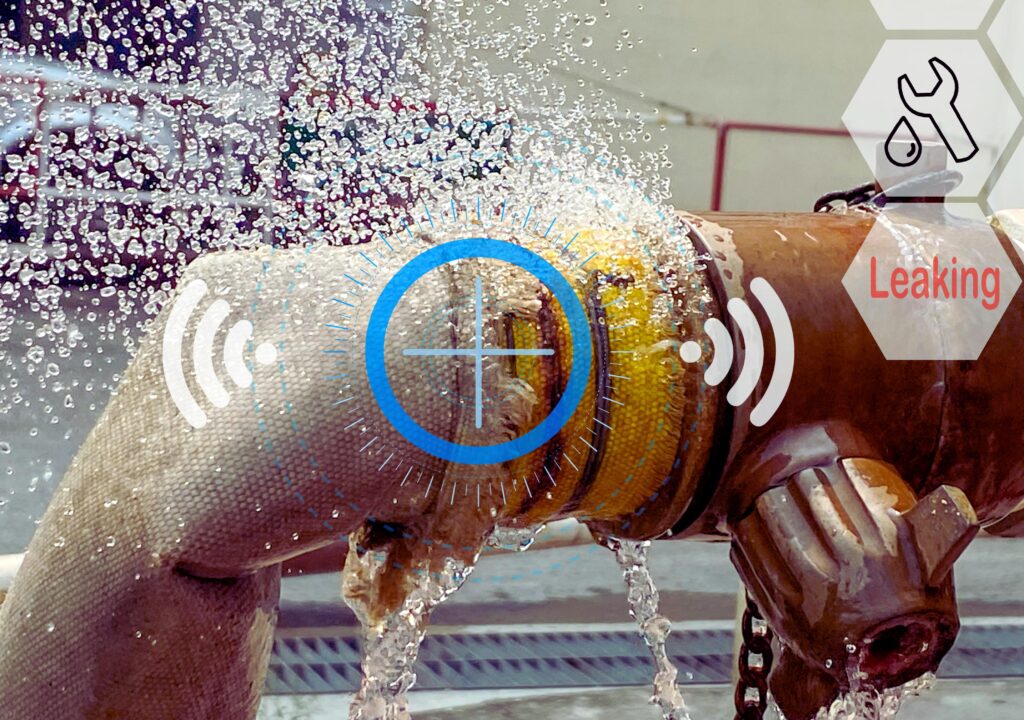

In the petrochemical industry, maintaining precise control over flow rates is essential for process stability and safety. Flow sensors monitor the movement of fluids through pipelines, providing data that can detect leaks, blockages, or other irregularities. Similarly, smart sensors on valves can ensure that they are functioning correctly, preventing issues such as valve sticking or malfunctioning that could lead to process disruptions or accidents.

In a pipeline system, for example, flow rate sensors can detect a decrease in flow that might indicate a partial blockage or leak. By detecting these anomalies early, maintenance teams can take corrective action before the issue escalates, minimizing downtime and preventing potential environmental hazards.

Benefits of Predictive Maintenance in the Petrochemical Industry

The adoption of predictive maintenance, powered by smart sensors, offers numerous benefits for petrochemical companies:

1. Reduced Downtime

Unplanned downtime is one of the costliest challenges in the petrochemical industry. A single equipment failure can bring production to a halt, leading to lost revenue, increased repair costs, and delays in supply chains. Predictive maintenance significantly reduces unplanned downtime by allowing companies to identify and address issues before they result in equipment failure. This leads to higher operational uptime and smoother production processes.

2. Improved Safety

Safety is a top priority in the petrochemical industry due to the hazardous nature of the materials involved. Equipment failure can lead to dangerous situations, including fires, explosions, and chemical spills. By predicting and preventing equipment failures, predictive maintenance enhances workplace safety, protecting workers and the environment.

For instance, predictive maintenance can help detect problems in pressure vessels before they reach a critical failure point, preventing potential explosions or hazardous material releases.

3. Optimized Maintenance Costs

Traditional maintenance approaches, such as scheduled maintenance, can result in over-servicing equipment, leading to higher costs and unnecessary downtime. Predictive maintenance, on the other hand, ensures that maintenance is performed only when needed, optimizing resource allocation. This reduces maintenance costs by eliminating unnecessary repairs and extending the lifespan of equipment through timely interventions.

4. Enhanced Asset Performance and Longevity

By continuously monitoring equipment health, predictive maintenance helps extend the lifespan of critical assets. Early detection of wear and tear allows maintenance teams to replace or repair components before they cause further damage to the machine. This proactive approach improves asset performance and reduces the need for costly replacements.

5. Data-Driven Decision Making

The data generated by smart sensors provides valuable insights into equipment performance and operational efficiency. Petrochemical companies can use this data to make informed decisions about maintenance schedules, production optimization, and capital investments. Over time, this data helps identify long-term trends in equipment performance, enabling continuous improvement and more effective asset management.

Real-World Applications of Predictive Maintenance in the Petrochemical Industry

Several leading petrochemical companies have successfully implemented predictive maintenance strategies using smart sensors, demonstrating the real-world benefits of this technology.

1. Shell’s Smart Maintenance Program

Shell, one of the largest petrochemical companies globally, has embraced predictive maintenance as part of its digital transformation strategy. By deploying smart sensors on critical equipment in its refineries and chemical plants, Shell has reduced unplanned downtime and improved safety. The company’s predictive maintenance program includes vibration monitoring, thermal imaging, and advanced analytics, enabling Shell to predict failures in pumps, compressors, and heat exchangers before they occur.

2. Chevron’s IoT-Based Predictive Maintenance

Chevron has also adopted IoT-enabled predictive maintenance across its petrochemical operations. By installing smart sensors on pipelines, pumps, and storage tanks, Chevron can monitor critical parameters and predict equipment failures. This approach has reduced maintenance costs and improved the reliability of Chevron’s assets, resulting in higher production efficiency and lower operational risks.

Conclusion

Predictive maintenance, driven by smart sensors, is revolutionizing the petrochemical industry by reducing downtime, improving safety, and optimizing maintenance costs. As the industry continues to face increasing pressure to enhance operational efficiency and minimize environmental impact, the adoption of predictive maintenance strategies is becoming a necessity.

With real-time monitoring and advanced analytics, petrochemical companies can predict equipment failures before they happen, ensuring smooth operations, extending the lifespan of assets, and maintaining a safe working environment. As more companies embrace predictive maintenance, the petrochemical industry is poised for a future where downtime is minimized, and efficiency is maximized through data-driven maintenance practices.