In this fast-evolving electronic environment, Printed Circuit Boards—PCBs—play a vital role in the functioning of almost every device we can think of. One type that really stands out within the industry is the FR4 PCB, which now has become the de facto standard for all high-performance applications. The major characteristics of the FR4 PCBs are the main subject of this article, together with their important features, benefits, and reasons why they prevail in an electronic design.

Understanding FR4 PCBs

What is a PCB?

A Printed Circuit Board is a flat board made from an insulating material on which conductive pathways are etched or printed. PCBs serve as the foundational element in electronic devices, providing the electrical connections necessary for components such as resistors, capacitors, and integrated circuits to function effectively.

FR4 Board

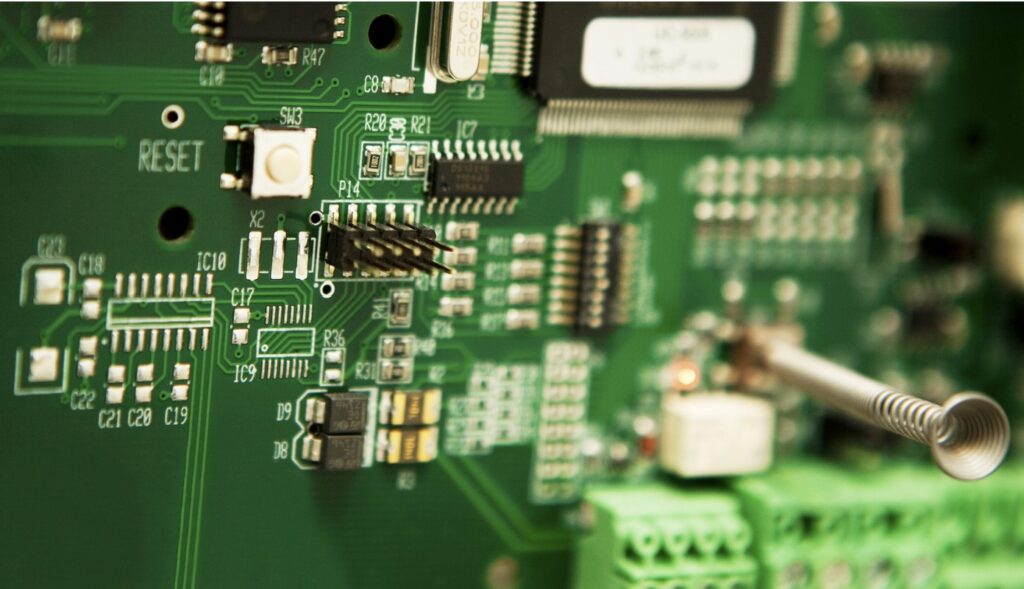

FR4 is a widely used material in the manufacturing of printed circuit boards (PCBs). It is a composite of woven fiberglass and epoxy resin, offering excellent mechanical strength, thermal stability, and electrical insulation properties. FR4 boards are popular in a range of electronic applications due to their durability and versatility, making them suitable for both consumer electronics and industrial equipment.

What Does the FR4 Stand For?

The term “FR4” stands for “Flame Retardant 4,” which designates a specific grade of fiberglass-reinforced epoxy laminate. The “FR” indicates that the material is flame retardant, meaning it has been treated to reduce flammability and improve safety during use. The “4” refers to the specific formulation of the material as standardized by the National Electrical Manufacturers Association (NEMA), ensuring consistent performance in various applications.

The Composition of FR4

FR4 PCB, or Flame Retardant 4 Printed Circuit Board, is a widely used material in the electronics industry due to its excellent electrical insulation properties and mechanical strength. Made from woven fiberglass and epoxy resin, FR4 is known for its durability and resistance to heat, making it ideal for a variety of applications, from consumer electronics to industrial machinery. Its versatility allows for intricate designs and high-density circuit layouts, which are essential in modern electronic devices. Additionally, FR4 PCBs can be manufactured in various thicknesses and copper weights, catering to specific project requirements. Overall, FR4 is a reliable choice for engineers and designers looking to create efficient and long-lasting electronic products!

However, FR4 is more than just a material; it’s a classification that denotes several important properties:

Flame Retardant:

FR4 is designed to resist ignition and limit the spread of fire, which is particularly crucial in electronic applications where overheating may occur.

Glass-Fiber Reinforced:

The glass fibers in FR4 offer excellent mechanical strength and durability, allowing for reliable performance in challenging environments.

Epoxy Resin:

The epoxy resin provides excellent electrical insulation properties, making FR4 PCBs suitable for high-frequency applications.

Design Variants

FR4 PCBs can be designed in various configurations, including single-sided, double-sided, and multi-layer options. The versatility in design allows engineers to create complex circuits tailored to specific requirements.

What is the Dielectric Constant of FR4 in PCB?

The dielectric constant of FR4 material typically ranges between 4.0 and 5.0, depending on the specific formulation and manufacturing process. This property is crucial because it affects the electrical performance of the PCB, influencing signal propagation speed and impedance characteristics. The relatively stable dielectric constant of FR4 makes it an ideal choice for many electronic applications, including high-frequency circuits.

Why Choose FR4 PCBs?

Electrical Performance

One of the most significant advantages of FR4 PCBs is their excellent electrical performance. The material has a relatively low dielectric constant, ensuring minimal signal loss and maintaining the integrity of the electronic signals. This characteristic is crucial in high-speed and high-frequency applications, such as telecommunications and computing.

Thermal Stability

FR4 offers good thermal stability, which is essential for electronic devices that generate heat during operation. The material can withstand elevated temperatures, reducing the risk of distortion or damage. This attribute is particularly vital in power electronics, where heat dissipation is a critical concern.

Mechanical Strength

The glass-fiber construction of FR4 provides superior mechanical strength, making these PCBs durable and resilient. This toughness allows them to endure the rigors of manufacturing processes, shipping, and operation in various environments. Whether it’s a consumer gadget or industrial machinery, FR4 PCBs hold up under pressure.

Cost-Effectiveness

In addition to their performance advantages, FR4 PCBs are cost-effective. The widespread availability of FR4 material combined with mature manufacturing processes keeps production costs relatively low. For businesses engaged in electronic design, this cost efficiency means that high-performance boards can be produced without exorbitant expenditures.

FR4 in Applications

FR4 PCBs are used across a wide array of applications, from consumer electronics to aerospace. Some common applications include:

Consumer Electronics:

Smartphones, tablets, and other gadgets rely on FR4 PCBs to ensure reliability and performance.

Industrial Equipment:

Machinery often incorporates FR4 PCBs for their strength and thermal stability.

Automotive:

Modern vehicles utilize FR4 for electronics governing critical systems like infotainment and engine management.

Telecommunications:

High-frequency circuits in communication devices use FR4 PCBs for efficient signal transmission.

What is the Difference Between Ceramic and FR4 PCB?

The primary difference between ceramic and FR4 PCBs lies in their material properties and applications. Ceramic PCBs are known for their superior thermal conductivity, high thermal stability, and excellent electrical insulation, making them suitable for high-performance applications, such as RF and microwave circuits. In contrast, FR4 PCBs are more cost-effective and easier to manufacture, making them ideal for a wide range of general electronic applications. While ceramic PCBs can handle higher temperatures and provide better heat dissipation, FR4 is often favored for its balance of performance and affordability in everyday electronics.

The Electronic Design Process with FR4 PCBs

Designing for FR4

When embarking on electronic design, engineers consider several factors when choosing FR4 PCBs:

Layer Count:

Depending on the complexity of the circuit, the number of layers in the PCB can vary. Multi-layer boards are especially useful for densely packed components.

Trace Width and Spacing:

The width of the conductive pathways impacts the board’s current-carrying capacity and must be designed with precision.

Routing Techniques:

Advanced routing techniques like blind/buried vias can be employed to optimize space and efficiency.

Thermal Management:

Mitigating thermal issues is essential in the design phase; appropriate layout and heat sinking techniques can be implemented to manage heat better.

Prototyping and Testing

Once the design is completed, prototyping follows. Rapid prototyping technologies allow engineers to quickly fabricate and test FR4 PCBs to identify any design flaws before mass production. Testing involves ensuring that the boards meet electrical specifications and can withstand the intended operational conditions.

Iteration and Improvement

The electronic design process is often iterative. Based on test results, designs can be modified to enhance performance or reduce costs. The modularity of FR4 PCBs allows for easy adjustments, making them a preferred choice among engineers.

Challenges in Working with FR4 PCBs

While FR4 PCBs have numerous advantages, they are not without challenges. Here are some common issues that designers may encounter:

Moisture Sensitivity

FR4 can absorb moisture, which can lead to degradation of performance in humid environments. Designers must consider environmental sealing and coatings to mitigate this issue.

Limited Frequency Range

While FR4 handles a variety of applications well, high-speed applications that exceed a certain frequency range might require materials with lower loss factors, such as PTFE or specialized laminates.

Thermal Limitations

Though FR4 has good thermal stability, there is a limit to the temperatures it can withstand. In applications with extreme thermal conditions, alternative materials may be necessary.

Future Trends in FR4 PCB Technology

As technology advances, so do the applications of FR4 PCBs. Key trends in the industry include:

Miniaturization

The push for smaller, more compact electronics has led to advancements in FR4 PCB miniaturization techniques, including finer trace widths, smaller vias, and more complex layering processes.

IoT and Smart Devices

With the rise of the Internet of Things (IoT) and smart devices, FR4 PCBs will continue to play a critical role in the connectivity and performance of these technologies.

Green and Sustainable Manufacturing

The industry is moving towards environmentally friendly practices. Manufacturers are exploring ways to produce FR4 PCBs using recyclable materials and eco-friendly processes.

Conclusion

FR4 PCBs have established themselves as the industry standard for high-performance electronics due to their excellent electrical, mechanical, and thermal properties. Their cost-effectiveness and versatility in design make them suitable for a broad range of applications, ensuring that they remain a cornerstone of modern electronic design. As technology continues to evolve, FR4 PCBs will adapt, paving the way for the next generation of innovative electronic solutions. Whether you’re an engineer involved in electronic design or a manufacturer looking to create reliable products, understanding the value of FR4 PCBs is essential in navigating the electronics landscape.