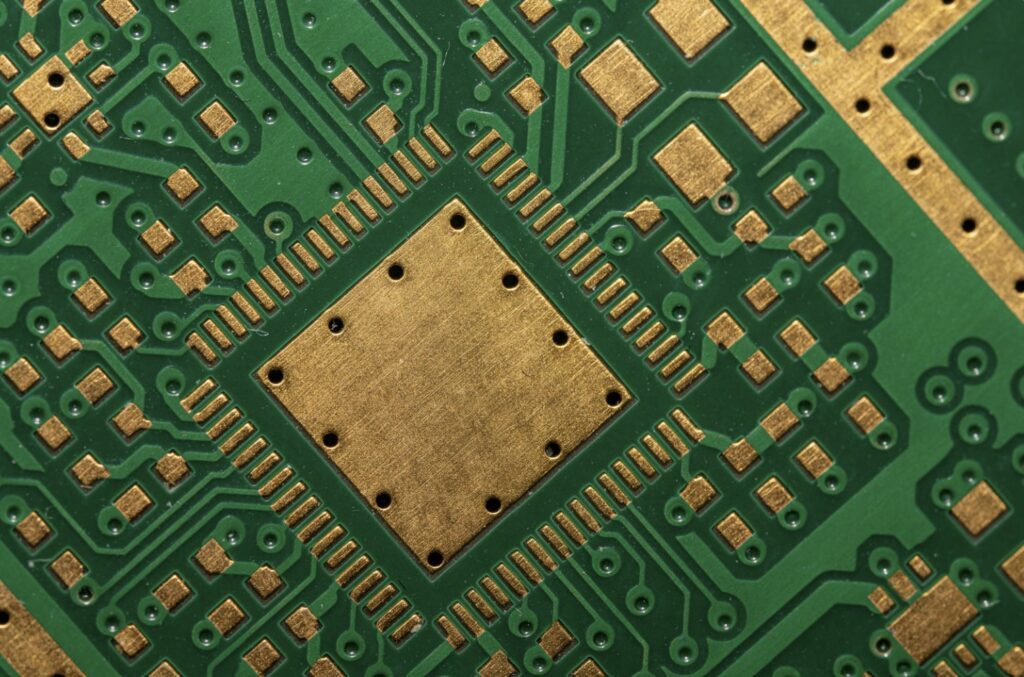

Printed Circuit Boards, or PCBs, are a fundamental element in modern electronics—it acts as the backbone that interlinks and supports various electronic components. The performance and efficiency of any device, from smartphones and computers to medical equipment and automotive technologies, depend strongly on the choice of PCB substrate. This paper presents various types of PCB substrates, together with their characteristics, and gives guidance on how to choose the best material for your particular electronic design needs.

What are PCB Substrates?

PCB substrates are the foundational layers on which electronic components are mounted and interconnected. They determine not only the physical structure of the PCB but also its electrical and thermal performance. The choice of substrate material can significantly influence factors such as signal integrity, thermal management, cost, and manufacturing capabilities.

Types of PCB Substrates

When it comes to PCB substrates, a range of materials are available. The most common types include:

1. FR-4 (Flame Retardant 4)

FR-4 is the most widely used substrate material for PCBs. It is a glass-reinforced epoxy laminate that provides excellent electrical insulation, mechanical strength, and dimensional stability. FR-4 substrates are relatively cost-effective and suitable for a variety of applications. However, they might not be ideal for high-frequency or high-temperature applications due to their limited thermal resistance.

2. Polyimide

Polyimide substrates, often used in flexible circuit boards, offer superior thermal stability and resistance to extreme conditions. They maintain performance at elevated temperatures, making them popular in aerospace, automotive, and high-performance computing applications. Polyimide’s flexibility allows for extraordinary design configurations but comes with a higher cost than traditional FR-4 material.

3. PTFE (Polytetrafluoroethylene)

PTFE substrates are known for their excellent dielectric properties and stability at high frequencies. As a result, they are commonly used in RF (radio frequency) and microwave applications. PTFE is also highly resistant to chemical environments. However, due to their cost and manufacturing complexities, PTFE PCBs are typically reserved for specialized applications.

4. Ceramic Substrates

Ceramic substrates are ideal for high-frequency applications due to their low dielectric loss and thermal conductivity. They can provide exceptional thermal dissipation required in high-power applications. However, ceramic PCBs can be brittle, and their manufacturing process tends to be more complex, leading to increased costs.

5. Metal Core PCBs

Metal core PCBs, typically made of aluminum or copper, are designed for applications that require efficient heat dissipation. They are particularly common in LED lighting and high-power electronics, where managing thermal buildup is critical. While they can enhance thermal management, metal core PCBs are heavier and may require more specialized manufacturing processes.

Applications of Different PCB Substrates

Understanding the applications corresponding to each substrate type can help guide your decision:

- FR-4 is excellent for general-purpose applications like consumer electronics, where cost and safety are priorities.

- Polyimide is favored in flexible circuits used in wearables, instrumentation, and aerospace.

- PTFE is ideal for high-frequency applications, such as telecommunications and satellite communications.

- Ceramic substrates are utilized in RF applications, high-temperature applications, and power electronics.

- Metal core PCBs are used primarily in LED lighting and high-power devices that require thermal management.

Factors to Consider When Choosing PCB Substrates

Selecting the right substrate material for your PCB design can be a complex process. Several factors should be considered to ensure optimal performance and compatibility with your electronic device.

1. Electrical Requirements

The electrical characteristics of the substrate play a critical role in PCB performance. Factors such as dielectric constant (Dk), dielectric loss (Df), and conductivity must be evaluated based on the intended application. For high-frequency or high-speed circuits, low-Dk and low-Df materials are essential to minimize signal loss and maintain signal integrity.

2. Thermal Conductivity

Understanding the thermal requirements of your PCB design is vital. If the circuit produces significant heat, selecting a substrate with high thermal conductivity (such as metal core PCBs or ceramic substrates) can help dissipate heat effectively, prolonging the lifespan of electronic components.

3. Environmental Considerations

The operating environment of your PCB should be taken into account. Will it be exposed to moisture, extreme temperatures, or corrosive substances? In harsher environments, substrates like polyimide or ceramics offer better resistance to environmental factors compared to traditional FR-4 materials.

4. Mechanical Properties

The mechanical strength of the substrate affects how well it can withstand handling, assembly, and operational stresses. If your device is exposed to vibrations, shocks, or flexing, choosing a substrate that provides the necessary mechanical integrity is crucial.

5. Cost and Manufacturing Capabilities

Cost considerations are paramount in electronic design. While high-performance substrates can offer superior benefits, they may not always fit within the project budget. Additionally, the complexity of manufacturing and special processing techniques can influence the overall cost and feasibility of using specific substrate materials.

Conclusion

Selecting the right PCB substrate is vital for ensuring the performance, efficiency, and reliability of electronic devices. A comprehensive understanding of the various substrate options, their characteristics, and the associated trade-offs is essential for making informed choices in the electronic design process. Whether you opt for cost-effective FR-4, high-performance polyimide, or specialized ceramic materials, each choice significantly influences your circuit’s functionality and longevity. It’s crucial to consider electrical, thermal, mechanical, and cost factors to align the substrate with the specific needs and operating conditions of your application.

For companies facing PCB substrate selection challenges, Arshon Technology stands ready to assist. As a leading PCB and electronic design firm, the company provides expert guidance in identifying the most suitable substrate materials tailored to specific project requirements. Their expertise lies in navigating the intricate trade-offs between cost, performance, and manufacturing capabilities, empowering clients to make informed decisions for their applications. Collaborating with Arshon Technology can enhance the reliability and efficiency of electronic devices while simplifying the design process, ensuring that designs are built to last.