The rapid advancement of technology has transformed the landscape of electronics manufacturing, making it more competitive and quality-driven than ever before. At the heart of this transformation lies the Printed Circuit Board (PCB), a fundamental component that enables electronic devices to function correctly. With increasing complexities in PCB design and an ever-present push for higher reliability, manufacturers face significant challenges in ensuring the flawless performance of their products. This is where Automatic Optical Inspection (AOI) comes into play.

AOI technology employs high-resolution imaging and sophisticated algorithms to provide a thorough inspection of PCBs during the manufacturing process. By automating the detection of defects, AOI not only enhances the quality assurance process but also drastically reduces the risk of errors that could lead to product failures. Detecting faults early in production not only saves time and resources but also fortifies the overall integrity of electronic devices. In this article, we will explore the mechanisms behind AOI, its benefits in PCB manufacturing, and the future implications of this vital technology in ensuring product quality and reliability

Understanding Automatic Optical Inspection (AOI)

Automatic Optical Inspection (AOI) is an innovative inspection process that utilizes sophisticated cameras and image processing algorithms to examine PCBs for defects. Typically employed in the manufacturing process, AOI provides a non-destructive means of evaluating the quality of PCBs at various stages, notably after soldering. The primary goal of AOI is to identify faults early, ensuring the manufacturing line remains efficient and the final product meets rigorous quality standards.

The Role of AOI in PCB Manufacturing

The importance of AOI in PCB manufacturing cannot be overstated. It addresses several critical issues:

1. Early Fault Detection: AOI enables the identification of defects in PCBs early in the production process. Detecting faults before subsequent manufacturing steps saves time and reduces costs associated with failed components.

2. High Inspection Speed: Unlike manual inspections, which can be labor-intensive and time-consuming, automated optical inspection systems can process PCBs quickly. This capability increases throughput and allows manufacturers to keep pace with rising demand.

3. Consistent Quality Control: Human inspectors can suffer from fatigue, leading to inconsistencies in inspection quality. AOI provides uniformity in inspections, ensuring that each board is evaluated against the same criteria without variation.

4. Wide Range of Defects: AOI is capable of detecting a variety of issues, including solder defects (such as insufficient solder, excess solder, and solder bridging), component misalignment, and missing components, as well as physical defects such as scratches and contaminations on the board.

How AOI Works

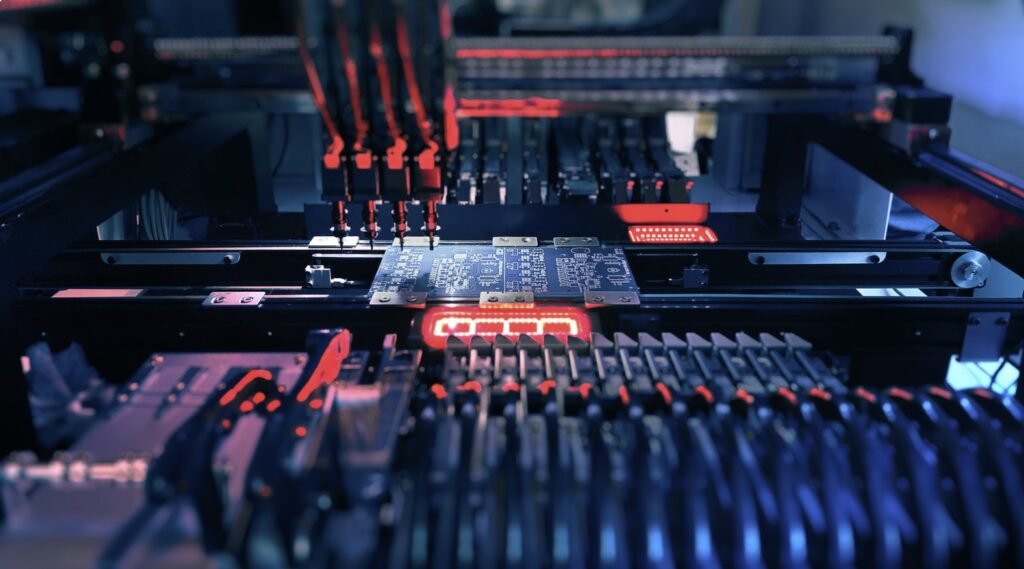

AOI systems typically comprise high-resolution cameras, powerful image processing software, and sometimes additional optical equipment like laser scanners. The inspection process generally follows these steps:

1. Image Capture:

The AOI machine captures high-resolution images of the PCB after the soldering process. This can occur in multiple angles and at different focal lengths to ensure comprehensive coverage.

2. Image Processing:

Using advanced algorithms, the captured images are analyzed. The software compares the images against a pre-defined reference model (known as a “golden board”). This reference encompasses the correct placements and solder characteristics for the components on the PCB.

3. Defect Identification:

The AOI system checks for various defects such as:

- Solder defects: Insufficient solder, excess solder, and solder bridging.

- Component issues: Misalignment, incorrect orientation, or missing components.

- Physical defects: Damage or contamination on the PCB surface.

4. Reporting

Upon completing the inspection, the system generates a comprehensive report detailing the results, including any defects found, their locations, and possible remedies.

Benefits of AOI for PCB Quality Assurance

Incorporating AOI into PCB manufacturing offers numerous advantages that contribute to overall product reliability:

1. Cost-Effectiveness

Early detection of faults significantly reduces the costs associated with rework or scrapping defective boards. By identifying issues at an early stage, manufacturers can avoid the higher costs related to late-stage discoveries that often require extensive rework or complete revisions.

2. Flexibility and Adaptability

Modern AOI systems are versatile and can be easily programmed to accommodate different PCB designs and configurations. This adaptability makes them ideal for manufacturers that produce a range of products or frequently update designs.

3. Integration with Manufacturing Systems

AOI systems can be integrated into broader manufacturing execution systems (MES). This integration enables real-time monitoring of quality metrics and production data, allowing for immediate corrective actions when defects are detected.

4. Enhancing Competitive Advantage

Manufacturers that implement AOI not only improve their quality assurance processes but also enhance their market competitiveness. By providing high-quality products with fewer defects, companies can improve customer satisfaction and loyalty.

5. Meeting Regulatory Standards

In many industries, particularly aerospace and medical devices, compliance with strict regulatory standards is essential. AOI provides the documentation and traceability needed to demonstrate compliance, further solidifying the reliability of the PCB and the devices that use them.

Challenges of AOI Implementation

While AOI provides significant benefits, its implementation is not without challenges. Manufacturers must navigate the following:

1. Initial Investment Costs

The initial cost of purchasing and setting up AOI systems can be substantial. However, this should be viewed as a long-term investment in quality assurance and efficiency.

2. Complexity of Board Designs

As PCB designs become more complex, AOI systems must be able to adapt accordingly. Not all systems can handle multilayered boards or boards with extremely dense components.

3. Need for Skilled Operators

While AOI is automated, it still requires skilled personnel to operate and maintain the systems effectively. The learning curve associated with these advanced technologies can be steep.

4. Calibration and Maintenance

Regular calibration and maintenance of AOI systems are crucial to ensure their accuracy over time. This process requires an ongoing commitment to quality assurance.

The Future of AOI in PCB Manufacturing

With trends pointing toward the miniaturization of electronics and the growing complexity of PCB designs, the role of AOI is set to expand. Emerging technologies, such as artificial intelligence (AI) and machine learning, will enhance AOI systems, enabling them to better analyze data and improve fault detection rates.

Furthermore, the integration of AOI with other manufacturing technologies, such as 3D X-ray inspection or In-Circuit Testing (ICT), could lead to hybrid systems that offer comprehensive inspection capabilities. This convergence of technologies will provide manufacturers with an even more robust toolkit for ensuring PCB quality.

Conclusion

In summary, Automatic Optical Inspection (AOI) stands out as a crucial innovation in the PCB manufacturing process, addressing the pressing need for quality assurance in an era of rapidly advancing technology. The ability to detect faults early not only mitigates the risk of costly production errors but also enhances the overall reliability of electronic devices. AOI systems offer manufacturers significant advantages, including increased efficiency, consistent inspection quality, and adaptability to various PCB designs.

As the industry faces challenges from complex circuitry and miniaturization, the integration of advanced technologies such as artificial intelligence into AOI systems paves the way for even greater accuracy and effectiveness in fault detection. This evolution will not only streamline production lines but also bolster manufacturers’ competitive edge in a dynamic market where product reliability is paramount.

Ultimately, embracing AOI technology is more than just an investment in equipment; it’s a commitment to excellence in manufacturing practices and customer satisfaction. As businesses continue to prioritize quality and efficiency, AOI will undoubtedly play a pivotal role in shaping the future of PCB manufacturing, ensuring that electronic devices are built to the highest standards of performance and reliability. Manufacturers that adopt AOI will be better positioned to meet the demands of tomorrow’s marketplace while delivering products that can be trusted to perform.