In today’s rapidly evolving technology landscape, the success of a product often hinges on its ability to seamlessly integrate cutting-edge electronics. Custom electronic design has emerged as a critical component of the product development process, offering businesses a competitive edge in the marketplace. By tailoring electronic systems to the specific needs of a product, companies can unlock enhanced functionality, improved performance, and greater efficiency – all of which are essential for driving innovation and capturing the attention of discerning consumers.

This blog post will explore the pivotal role of custom electronic design in product development, highlighting the key benefits, challenges, and best practices that businesses should consider when undertaking this essential process. Whether you’re developing a new consumer electronics device, an industrial automation system, or a cutting-edge medical technology, understanding the importance of custom electronic design will be crucial for ensuring your product’s success.

The Advantages of Custom Electronic Design

One of the primary benefits of custom electronic design is the ability to optimize a product’s functionality and performance. By designing electronic systems from the ground up, engineers can ensure that every component is perfectly calibrated to the specific requirements of the product, leading to enhanced efficiency, greater reliability, and improved user experiences.

For example, in the case of a wearable fitness tracker, custom electronic design would allow the engineers to create a highly specialized sensor array that can precisely monitor a user’s heart rate, activity levels, and sleep patterns. This level of personalization would be difficult to achieve with off-the-shelf electronic components, which are often designed for general-purpose applications.

Moreover, custom electronic design enables businesses to differentiate their products in a crowded marketplace. By incorporating unique features and capabilities that are tailored to the specific needs of their target audience, companies can establish a strong brand identity and stand out from their competitors.

Another key advantage of custom electronic design is its ability to drive down long-term costs. By optimizing the electronic systems for efficiency and performance, businesses can reduce power consumption, minimize the need for costly maintenance and upgrades, and ultimately improve the overall cost-effectiveness of their products.

How Can Custom Electronic Design Provide Advantages In Some Key sectors?

Consumer Electronics:

By tailoring the electronic systems to the specific needs of their target consumers, companies can develop products with enhanced user experiences, improved performance, and greater energy efficiency. This customization can be a powerful differentiator in a crowded marketplace, helping brands stand out and build loyal customer bases.

Industrial Automation:

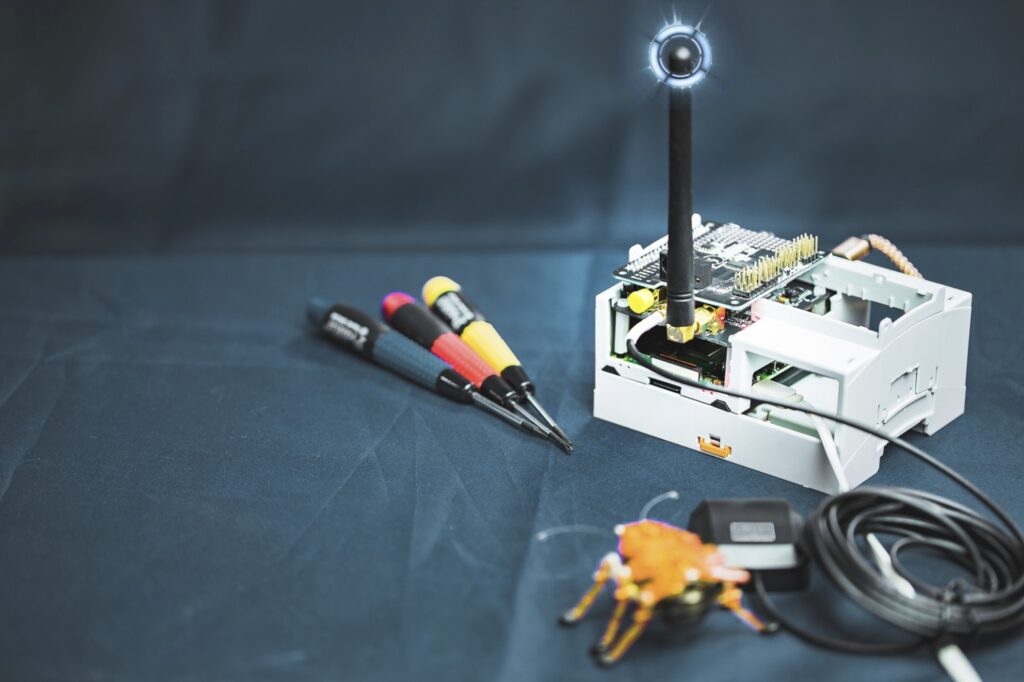

In the industrial automation sector, custom electronic design is essential for creating reliable, high-performance control systems that can withstand the rigors of harsh environments. By designing specialized electronic components and integrated systems, engineers can optimize for factors like durability, precision, and energy efficiency – all of which are critical for ensuring the smooth and reliable operation of industrial equipment and processes.

Automotive Electronics:

The automotive industry has seen a rapid increase in the integration of electronic systems, from advanced driver assistance features to infotainment systems. Custom electronic design allows automakers to develop specialized electronic components and control units that are seamlessly integrated with the vehicle’s mechanical systems, resulting in improved performance, enhanced safety, and a more immersive driving experience for consumers.

Medical Devices:

In the medical device industry, custom electronic design is essential for creating innovative, life-saving technologies. By designing specialized electronic systems for applications like diagnostic equipment, prosthetics, and implantable devices, engineers can ensure that these critical products meet the stringent safety, reliability, and performance requirements of the healthcare sector. This customization can be a key differentiator in a highly regulated industry.

Renewable Energy:

The renewable energy industry relies heavily on custom electronic design to optimize the performance and efficiency of its systems. From solar inverters to wind turbine control units, the electronic components that power these clean energy solutions must be tailored to the specific demands of the application, ensuring maximum energy output, grid integration, and reliable operation.

Overcoming the Challenges of Custom Electronic Design

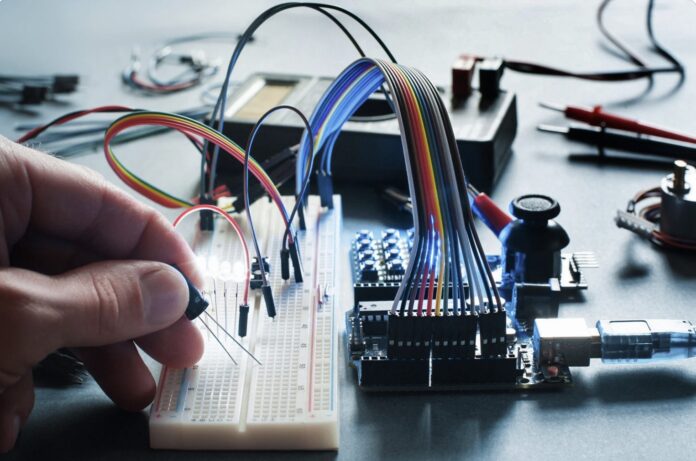

While the benefits of custom electronic design are substantial, the process is not without its challenges. One of the primary hurdles is the increased complexity and time-to-market associated with this approach. Designing a custom electronic system from scratch requires a deep understanding of the product’s requirements, as well as specialized expertise in areas such as circuit design, firmware development, and system integration.

To overcome these challenges, businesses must invest in a highly skilled and experienced engineering team, equipped with the latest tools and technologies. This can be a significant investment, both in terms of time and resources, and may require companies to reevaluate their product development timelines and budgets.

Another challenge lies in the need for robust testing and validation processes. Custom electronic systems must be thoroughly tested to ensure their reliability, safety, and compliance with industry standards. This can be a time-consuming and complex process, requiring specialized equipment and expertise.

Moreover, the integration of custom electronic design with other aspects of the product development process, such as mechanical design and software development, can also present unique challenges. Effective communication and collaboration between cross-functional teams are essential to ensure seamless integration and a cohesive final product.

Best Practices for Successful Custom Electronic Design

To navigate the complexities of custom electronic design and unlock its full potential, businesses should consider the following best practices:

1. Clearly define product requirements:

Before embarking on the custom electronic design process, it’s crucial to have a thorough understanding of the product’s specific requirements, including its intended use, target market, and performance objectives. This will help guide the design process and ensure that the final product meets the needs of the end-user.

2. Invest in a skilled engineering team:

Successful custom electronic design requires a team of highly skilled and experienced engineers, with expertise in areas such as circuit design, firmware development, and system integration. Investing in the right talent can be the difference between a successful product and a costly failure.

3. Embrace a collaborative approach:

Custom electronic design often involves close collaboration between cross-functional teams, including mechanical engineers, software developers, and product managers. Fostering a culture of open communication and information-sharing can help to ensure that the final product is a cohesive and well-integrated solution.

4. Prioritize testing and validation:

Rigorous testing and validation processes are essential for ensuring the reliability, safety, and compliance of custom electronic systems. This may include a range of testing protocols, such as environmental stress testing, electromagnetic compatibility (EMC) testing, and safety certification.

5. Leverage the latest tools and technologies:

The field of custom electronic design is rapidly evolving, with the introduction of new tools and technologies that can streamline the design process and improve the overall quality of the final product. Staying up-to-date with the latest advancements in areas such as computer-aided design (CAD) software, simulation tools, and rapid prototyping can give businesses a competitive edge.

Conclusion

By leveraging the benefits of custom electronic design, companies can unlock a host of advantages, including improved performance, increased efficiency, and reduced long-term costs.

However, the complexity and challenges associated with custom electronic design should not be underestimated. Businesses must be willing to invest in a skilled engineering team, embrace a collaborative approach, and prioritize robust testing and validation processes to ensure the success of their custom electronic systems.

As the pace of technological change continues to accelerate, the importance of custom electronic design will only grow. By staying ahead of the curve and adopting best practices in this essential discipline, businesses can position themselves for long-term success and deliver innovative, high-performing products that captivate the hearts and minds of consumers.