In the world of electronics, the efficient management of heat is a critical concern, especially in high-power circuits. The printed circuit board (PCB) plays a pivotal role in this process, as its thermal conductivity directly impacts the ability to dissipate heat generated by components. Understanding the principles of PCB thermal conductivity and the various strategies for thermal management is essential for designing reliable and high-performing electronic systems.PCB Thermal Conductivity: Managing Heat in High-Power Circuits

PCB Thermal Conductivity Fundamentals

At the heart of PCB thermal management lies the concept of thermal conductivity. This property, measured in watts per meter-kelvin (W/m-K), describes a material’s ability to conduct heat. In the context of PCBs, thermal conductivity is influenced by the composition and structure of the board.

Conventional FR-4 (Flame Retardant 4) PCBs, the most commonly used substrate material, have relatively low thermal conductivity, typically ranging from 0.2 to 0.4 W/m-K. This limited heat transfer capability can pose challenges when dealing with high-power components or circuits that generate significant amounts of heat.

To address this, manufacturers have developed specialized PCB materials with enhanced thermal conductivity. These include:

1. Metal-Core PCBs:

These boards incorporate a metal layer, usually copper or aluminum, as the core, which acts as a highly conductive heat dissipation path. Metal-core PCBs can have thermal conductivity values ranging from 1 to 4 W/m-K, significantly improving the board’s ability to manage heat.

2. Ceramic-Filled PCBs:

By incorporating ceramic fillers, such as aluminum nitride or boron nitride, into the substrate, PCB manufacturers can increase the overall thermal conductivity of the board, typically reaching 1 to 2 W/m-K.

3. Graphite-Based PCBs:

Utilizing graphite-based materials, which have excellent thermal conductivity (typically 100 to 400 W/m-K), these specialized PCBs offer superior heat dissipation capabilities.

The choice of PCB material with appropriate thermal conductivity is crucial in high-power applications, such as power electronics, LED lighting, and high-performance computing, where effective heat management is essential for reliable operation and extended component lifespan.

PCB Thermal Management Strategies

Beyond the selection of PCB materials, there are various thermal management strategies that designers can employ to optimize heat dissipation and ensure the reliable operation of high-power circuits. These strategies include:

1. Copper Thickness and Copper Layers:

Increasing the copper thickness or the number of copper layers in a PCB can significantly enhance the board’s thermal conductivity. Thicker copper traces and additional copper layers provide more efficient heat transfer paths, allowing for better heat dissipation.

2. Thermal Vias:

Thermal vias are plated-through holes that connect the copper layers within a PCB, creating a vertical heat transfer pathway. These vias act as thermal bridges, facilitating the movement of heat from hot components to the board’s outer layers, where it can be more effectively dissipated.

3. Heat Sinks and Cooling Mechanisms:

Integrating heat sinks, fans, or other cooling mechanisms directly onto the PCB can greatly improve the overall thermal management of the system. These solutions help to actively remove heat from the board, reducing the thermal load on critical components.

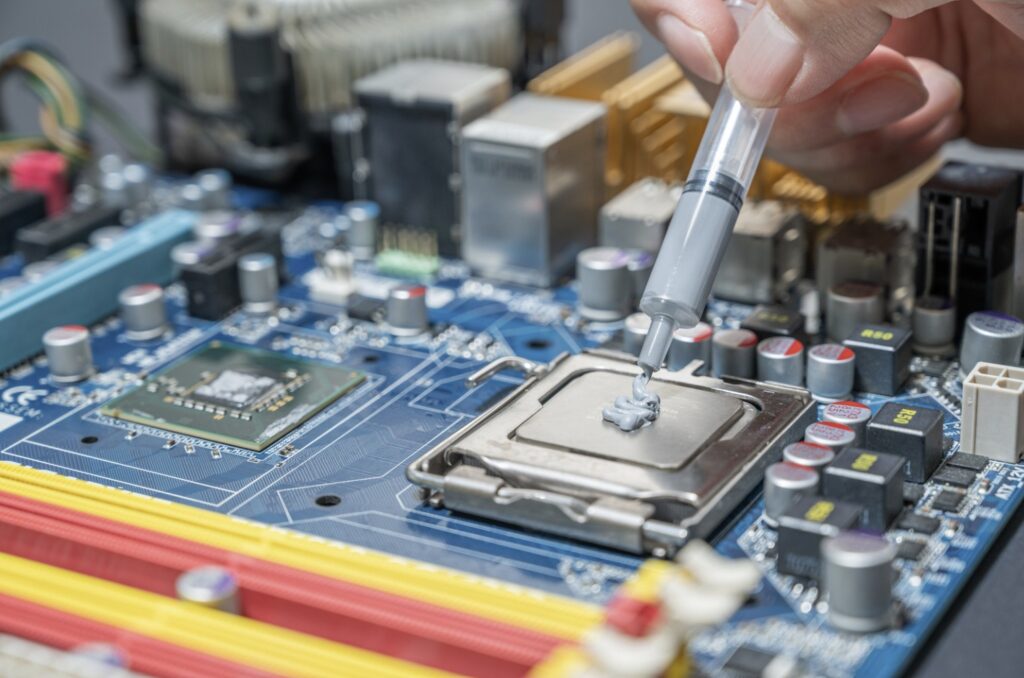

4. Thermal Interface Materials (TIMs):

Thermal interface materials, such as thermal greases, pads, or phase-change materials, are used to fill the gaps between the PCB and heat-generating components or heat sinks. These materials optimize heat transfer by improving the thermal contact between surfaces, reducing thermal resistance and enhancing heat dissipation.

5. Layout and Component Placement:

The physical layout of the PCB and the placement of components can significantly impact thermal management. Careful component placement, ensuring adequate spacing, and strategic routing of high-power traces can help minimize hot spots and facilitate efficient heat transfer.

6. Simulation and Thermal Modeling:

Utilizing thermal simulation and modeling tools during the PCB design process can provide valuable insights into the board’s thermal behavior. These tools allow designers to analyze heat distribution, identify potential hot spots, and evaluate the effectiveness of various thermal management strategies before the physical prototype is manufactured.

7.Power Dissipation Considerations:

– Minimize power losses in the circuit by optimizing efficiency and reducing resistive/switching losses.

– Use low on-resistance components and consider paralleling devices to distribute power dissipation.

– Operate components within their safe operating area and derate as needed for high-temperature environments.

8. Airflow and Ventilation:

– Ensure adequate ventilation and airflow around the circuit, either through natural convection or forced airflow.

– Consider enclosure design and placement to facilitate heat dissipation.

– Avoid obstructing airflow paths or airflow to critical components.

The specific techniques used will depend on the power levels, component types, and application requirements of the high-power circuit. Careful thermal management is crucial for reliable and safe operation.

PCB Fabrication Considerations

Alongside the thermal management strategies, the PCB fabrication process plays a crucial role in ensuring the effective implementation of thermal conductivity principles. Some key considerations during PCB fabrication include:

1. Material Selection: The choice of PCB substrate material, copper thickness, and other layer stackup components directly impact the board’s thermal performance.

2. Copper Plating and Etching: Precise control over the copper plating and etching processes is essential to maintain the desired copper thickness and ensure consistent thermal conductivity across the PCB.

3. Thermal Via Fabrication: The manufacturing of thermal vias, including their size, spacing, and plating quality, can significantly influence the overall heat transfer capabilities of the board.

4. Surface Finish: The selection of the appropriate surface finish, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), can affect the thermal interface between the PCB and heat-generating components or heat sinks.

5. Quality Control: Rigorous quality control measures during the PCB fabrication process, such as testing for thermal performance and ensuring consistent manufacturing standards, are crucial to deliver reliable, high-performing boards.

Conclusion

Effective management of heat in high-power circuits is a critical aspect of PCB design and fabrication. Understanding the principles of PCB thermal conductivity and the various thermal management strategies is essential for engineers and designers working in industries where reliable and efficient heat dissipation is paramount.

By leveraging specialized PCB materials, implementing thermal management techniques, and carefully considering the fabrication process, designers can create PCBs that can effectively handle the thermal challenges posed by high-power electronics. This holistic approach to PCB thermal management ensures the long-term reliability, performance, and safety of electronic systems in a wide range of applications.