Introduction

Brushless DC motors (BLDC) have become a popular choice in various applications due to their efficiency, reliability, and performance. Unlike traditional brushed motors, BLDC motors operate without mechanical brushes and commutators, offering several advantages. This article provides a comprehensive overview of BLDC motors, detailing their working principles, advantages, and disadvantages.

What is a BLDC Motor?

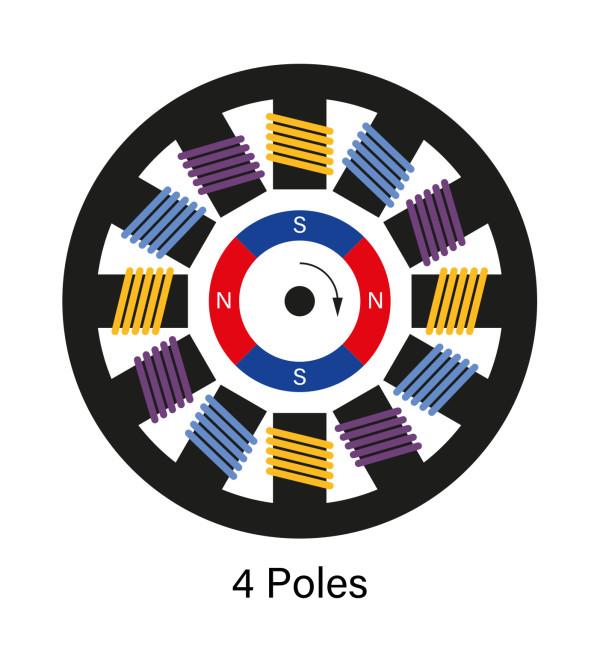

A Brushless DC motor (BLDC) is a type of electric motor that relies on electronic commutation instead of mechanical brushes and commutators. BLDC motors consist of a rotor, which is typically a permanent magnet, and a stator, which contains the windings. The electronic controller provides the necessary current to the stator windings, creating a rotating magnetic field that drives the rotor.

Working Principle of BLDC Motors

Components of a BLDC Motor

1. Stator: The stationary part of the motor, consisting of windings.

2. Rotor: The rotating part of the motor, typically made of permanent magnets.

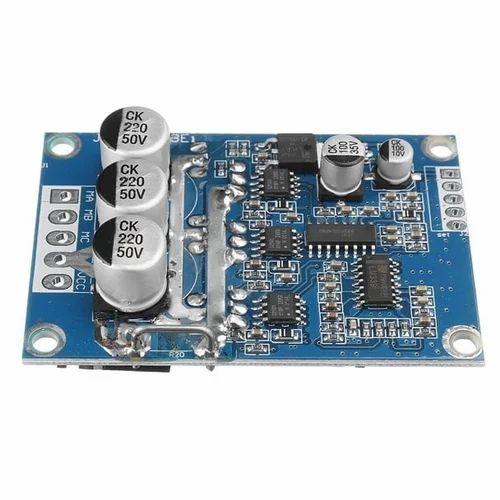

3. Electronic Controller: Manages the current flow to the windings, ensuring the motor operates efficiently.

Operation

The electronic controller supplies current to the stator windings in a precise sequence, generating a rotating magnetic field. This magnetic field interacts with the permanent magnets on the rotor, causing it to rotate. The controller continuously adjusts the current to maintain the rotor’s motion, providing smooth and efficient operation.

Advantages of BLDC Motors

High Efficiency

BLDC motors are known for their high efficiency, primarily due to the absence of mechanical brushes, which eliminates frictional losses. This results in lower energy consumption and reduced heat generation.

Long Lifespan

The lack of brushes in BLDC motors reduces wear and tear, leading to a longer lifespan. This makes them ideal for applications where maintenance is challenging or costly.

High Power Density

BLDC motors offer a high power-to-weight ratio, providing significant power output in a compact size. This makes them suitable for applications with space constraints, such as electric vehicles and drones.

Precise Control

The electronic controller in BLDC motors allows for precise control over speed and torque. This makes them ideal for applications requiring accurate motion control, such as robotics and CNC machines.

Low Noise and Vibration

BLDC motors operate quietly and with minimal vibration, making them suitable for applications where noise reduction is essential, such as household appliances and medical equipment.

Better Thermal Management

Due to their high efficiency and lower heat generation, BLDC motors have better thermal management compared to brushed motors. This enhances their performance and reliability, especially in high-power applications.

Versatility

BLDC motors can be used in a wide range of applications, from small devices like computer fans to large systems like electric vehicles. Their adaptability and performance make them a popular choice across various industries.

Disadvantages of BLDC Motors

Higher Initial Cost

One of the primary disadvantages of BLDC motors is their higher initial cost compared to brushed motors. The electronic controller and the need for precise components contribute to the increased cost.

Complex Control Systems

BLDC motors require sophisticated electronic controllers to operate effectively. This complexity can make the design and implementation process more challenging, requiring specialized knowledge and expertise.

Sensitivity to Environmental Conditions

BLDC motors can be sensitive to harsh environmental conditions, such as extreme temperatures and moisture. This can affect their performance and lifespan, necessitating protective measures in certain applications.

Electromagnetic Interference (EMI)

The electronic switching in BLDC motors can generate electromagnetic interference (EMI), which may affect nearby electronic devices. Proper shielding and filtering are required to mitigate this issue.

Maintenance of Controllers

While the motors themselves are low-maintenance, the electronic controllers require regular maintenance and updates to ensure optimal performance. This can add to the overall maintenance requirements.

Limited Speed Range

Although BLDC motors offer precise control, their speed range is limited compared to some other motor types. This may restrict their use in applications requiring extremely high or variable speeds.

Applications of BLDC Motors

Automotive Industry

– Electric Vehicles (EVs): BLDC motors are widely used in electric vehicles due to their high efficiency, compact size, and excellent performance.

– Power Steering: BLDC motors provide precise control and reliability in electric power steering systems.

– Cooling Fans: The low noise and high efficiency of BLDC motors make them ideal for automotive cooling fans.

Consumer Electronics

– Computer Fans: The quiet operation and reliability of BLDC motors make them perfect for cooling computer systems.

– Household Appliances: BLDC motors are used in washing machines, refrigerators, and air conditioners for their efficiency and low noise.

Industrial Applications

– Robotics: The precise control and high power density of BLDC motors make them suitable for robotic arms and automated systems.

– CNC Machines: BLDC motors provide accurate motion control, essential for CNC machining operations.

– Conveyor Systems: Their reliability and efficiency make BLDC motors ideal for industrial conveyor systems.

Medical Equipment

– Surgical Tools: The low noise and precise control of BLDC motors are beneficial in surgical tools and medical devices.

– Ventilators: BLDC motors are used in ventilators due to their reliability and quiet operation.

Aerospace

– Drones: The high power density and efficiency of BLDC motors make them perfect for powering drones and UAVs (Unmanned Aerial Vehicles).

– Aircraft Systems: BLDC motors are used in various aircraft systems for their reliability and performance.

Renewable Energy

– Wind Turbines: BLDC motors are used in small wind turbines for their efficiency and low maintenance requirements.

– Solar Trackers: Their precise control and reliability make BLDC motors suitable for solar tracking systems.

Conclusion

Brushless DC motors (BLDC) offer numerous advantages, including high efficiency, long lifespan, high power density, precise control, low noise, and better thermal management. However, they also come with disadvantages such as higher initial cost, complex control systems, sensitivity to environmental conditions, electromagnetic interference, maintenance of controllers, and limited speed range.

Despite these challenges, the benefits of BLDC motors make them a popular choice across various industries, including automotive, consumer electronics, industrial applications, medical equipment, aerospace, and renewable energy. Understanding the advantages and disadvantages of BLDC motors can help in making informed decisions about their implementation in different applications.

By leveraging the strengths of BLDC motors and addressing their limitations, industries can achieve improved performance, efficiency, and reliability in their products and systems. Contact Arshon Technology, so they can help you with your BLDC selection and design of the controller.