Sensors have become the unsung heroes of the digital age, quietly enabling everything from smartphones and fitness trackers to industrial machinery and autonomous vehicles. Whether measuring temperature, pressure, motion, or light, sensors are integral components in modern electronic systems. For companies involved in electronic product development, the ability to design and integrate sensors effectively can make the difference between a successful product and one that struggles in the marketplace. Sensor design services—offered by specialized firms like Arshon Technology—are at the forefront of this evolution, providing custom electronic design solutions tailored to specific industry needs. This article explores how sensors are shaping modern electronics, the benefits they bring to electronic design, the industries that rely heavily on sensor integration, and the challenges and considerations involved in developing and implementing sensor-based systems.

1. Introduction to Sensor Design Services

Sensor design services refer to the specialized process of conceptualizing, creating, testing, and integrating sensors into electronic products. This can involve customizing existing sensor technologies or developing entirely new sensing methods to address unique requirements. The goal is to ensure that the final product can collect and interpret real-world data reliably, accurately, and efficiently.

These services encompass various disciplines, such as electrical engineering, materials science, embedded systems design, software development, and even machine learning and data analytics. Because sensors are often subjected to harsh or unpredictable environments, sensor design services also need to consider factors like durability, power consumption, calibration routines, and communication protocols. Consequently, sensor design is not just about picking the right component off the shelf; it is about crafting an entire sensing solution that seamlessly fits within the larger system’s architecture.

For companies in need of end-to-end solutions, specialized firms like Arshon Technology offer a comprehensive approach. They work from concept to final product, ensuring the sensor not only meets performance requirements but is also optimized for manufacturing, cost-effectiveness, and long-term reliability. This focus on specialized, custom electronic design underscores the importance of sensor performance in modern electronic product development.

2. The Role of Sensors in Modern Electronics

Modern electronics rely on sensors for an ever-expanding array of applications. Today’s devices must go beyond simple functionality; they must detect and respond to their surroundings, gather usage metrics, and communicate wirelessly. Here are just a few of the critical roles sensors play:

- Data Collection: Sensors are the gateway through which digital devices perceive the physical world. By converting analog signals (like temperature, pressure, vibration, or light) into digital data, sensors enable devices to adapt their operations in real-time.

- Automation and Control: Sensors drive automated processes by providing real-time feedback to control systems. In industrial and manufacturing settings, sensor data can detect anomalies, control robotic systems, and regulate conditions on production lines to ensure quality and efficiency.

- User Experience: In consumer electronics, sensors elevate user engagement and convenience. Motion sensors enable gesture control, while environmental sensors adjust device settings based on ambient conditions. This level of interactivity has become a hallmark of the modern user experience.

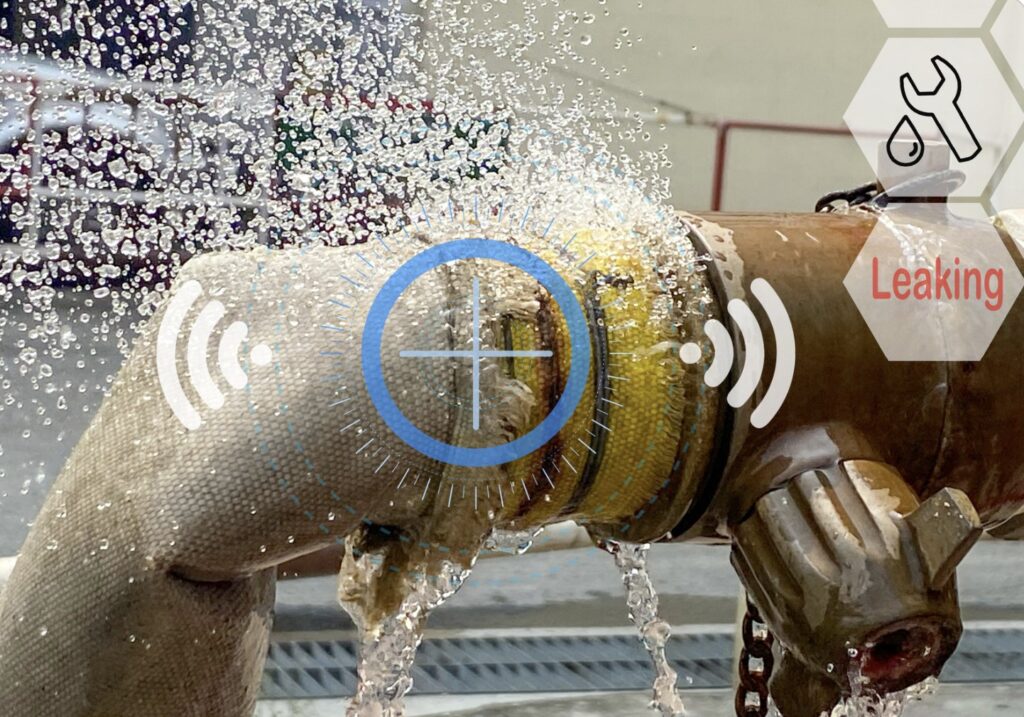

- Predictive Maintenance: Increasingly, sensors are at the heart of predictive maintenance solutions in industries such as automotive, aviation, and heavy machinery. By continuously monitoring equipment health, sensor data can forecast potential failures, thus avoiding downtime and reducing maintenance costs.

- Internet of Things (IoT) Integration: Sensors form the foundational layer of IoT ecosystems. Each sensor node collects data and sends it to a cloud platform for aggregation and analysis, enabling a wide range of services—from smart home automation to city-wide infrastructure monitoring.

Given these roles, sensor design services are essential to ensuring that sensors meet the precise demands of each application. Durability, precision, and data integrity are non-negotiable attributes, which is why custom electronic design firms devote substantial time to perfecting sensor architecture and interfacing.

3. Benefits of Sensor Integration in Electronic Design

When integrated correctly, sensors offer numerous benefits that can significantly enhance a product’s functionality, reliability, and market competitiveness. Some of the key advantages include:

- Enhanced Product Capabilities: By adding sensors to a device, manufacturers can expand its feature set. For instance, a wearable device that was originally just a step counter can be upgraded to track heart rate, body temperature, or even blood oxygen levels.

- Improved Efficiency: Sensor-driven feedback loops allow electronics to operate more efficiently. From temperature regulation in data centers to automatic brightness adjustments in mobile devices, sensors ensure systems consume only the resources they need.

- High Precision and Accuracy: Modern sensor technologies can measure parameters with remarkable accuracy. This precision can be critical in industries such as healthcare, aviation, and automotive, where tiny deviations can lead to significant outcomes.

- Better User Engagement and Experience: Sensors enable more intuitive user interactions. Touch sensors, motion sensors, and environmental sensors can automatically adjust device settings in real-time based on user preferences or environmental conditions.

- Cost Savings Over Time: While there might be an initial investment in sensor design services, effective sensor integration can reduce long-term operating costs. Predictive maintenance sensors, for example, minimize downtime by catching potential issues early.

- Data-Driven Insights: The data collected from sensors can provide valuable insights for both manufacturers and end-users. These insights can guide product improvements, optimize production processes, or uncover new business opportunities.

Ultimately, these benefits emphasize why many organizations seeking to innovate in electronic product development choose to invest in custom electronic design services. With a partner like Arshon Technology, companies can ensure that sensor integration is done seamlessly, meeting performance requirements without sacrificing cost-effectiveness or time-to-market.

4. Industries Benefiting from Sensor Design

4.1 Automotive and Transportation

In the automotive sector, sensors are central to evolving vehicle designs. Modern cars contain dozens of sensors that monitor everything from engine performance to tire pressure, air quality in the cabin, and driver biometrics. Advanced Driver Assistance Systems (ADAS) rely on cameras, radar, LiDAR, and ultrasonic sensors to enable features like automatic emergency braking, adaptive cruise control, and self-parking. As the industry moves towards autonomous driving, the complexity and importance of sensor arrays will only increase.

4.2 Healthcare and Medical Devices

Healthcare technology has undergone a significant transformation thanks to sensors. Wearable devices can continuously track vital signs like heart rate, blood oxygen level, and ECG patterns, enabling proactive health monitoring. In hospitals, advanced sensor technologies contribute to patient safety—infusion pumps, robotic surgical systems, and imaging devices rely on high-precision sensors to deliver accurate readings and real-time feedback. Custom electronic design for medical devices ensures compliance with stringent safety standards and real-world patient needs.

4.3 Industrial Automation and Manufacturing

Factories and production facilities worldwide use sensor-driven automation to streamline processes and ensure product quality. Machine vision systems spot production defects, while temperature and humidity sensors stabilize the production environment. Vibration and acoustic sensors detect machine wear and prevent costly breakdowns. By utilizing robust sensor design services, industrial facilities can integrate sensors that endure harsh conditions (extreme heat, chemical exposure, or vibration) while maintaining accuracy.

4.4 Consumer Electronics

From smartphones and gaming consoles to smart TVs and wearables, consumer electronics integrate sensors for user-centric experiences. These sensors range from gyroscopes and accelerometers for motion detection to light sensors for auto-brightness settings. The competition in consumer electronics is fierce, making sensor performance a critical differentiator. Electronic design that prioritizes sensor accuracy and user experience can help companies stand out in a crowded market.

4.5 Aerospace and Defense

Mission-critical applications in aerospace and defense demand the highest levels of reliability and resilience. Sensors must operate flawlessly under extreme conditions such as high altitudes, zero gravity, and exposure to radiation. In aircraft, sensors monitor cabin pressure, altitude, and structural integrity. In defense applications, sensors can support surveillance, targeting systems, and threat detection. Sensor design services are indispensable in these industries, ensuring safety and reliability when it matters most.

4.6 Internet of Things (IoT) and Smart Cities

IoT has expanded the scope of sensor deployment to include smart homes, smart cities, and connected infrastructure. Sensors in this context can range from simple, low-power devices that measure room temperature to complex networks monitoring traffic, pollution levels, and utility usage across an entire city. Custom electronic design ensures that these sensors are optimized for low power consumption, robust wireless communication, and easy scalability. By gathering environmental data, cities can make informed decisions about resource allocation, public safety, and sustainability efforts.

5. Challenges and Considerations in Sensor Design

While sensors offer immense potential, developing and integrating them into products is no simple task. Here are some of the primary challenges and considerations:

- Choosing the Right Sensor Technology: Selecting the wrong sensor can result in inaccurate data, increased costs, or product failure. Engineers must weigh factors such as range, sensitivity, power consumption, and durability.

- System Integration: In electronic design, sensors do not operate in isolation. They must interface seamlessly with microcontrollers, signal conditioning circuits, power supplies, and communication modules. Ensuring all these components work together without interference or noise is a significant engineering challenge.

- Calibration and Testing: Sensors often require periodic calibration to maintain accuracy. Designing easy-to-calibrate systems (or self-calibrating sensors) can reduce long-term maintenance costs and complexities.

- Environmental and Regulatory Compliance: Different industries have specific regulations (like ISO standards in manufacturing or FDA approval in medical devices). Sensors must meet these regulatory requirements, which can involve rigorous testing and documentation.

- Reliability and Redundancy: In safety-critical applications such as aerospace or medical equipment, sensor failure is not an option. Designing redundancy and fail-safe mechanisms adds another layer of complexity.

- Power Management: For battery-powered or remote devices, power consumption is a critical consideration. Designing sensors and their accompanying circuits to minimize power draw is paramount, particularly in IoT and wearable applications.

- Cost-Effectiveness: Balancing performance with cost is a key aspect of electronic product development. While high-performance sensors might deliver greater accuracy, they can increase the overall product price. Companies must weigh these trade-offs to stay competitive.

6. How Arshon Technology Contributes to Successful Sensor Design

Among the various service providers in the sensor design landscape, Arshon Technology stands out for its comprehensive approach. Leveraging expertise in custom electronic design, Arshon collaborates closely with clients to understand their specific needs, application environments, and market constraints. Key differentiators include:

- Tailored Solutions: Rather than forcing off-the-shelf components into a design, Arshon evaluates multiple sensor options and selects or designs the one best suited for the project’s goals.

- Rapid Prototyping: Shortening the design cycle is essential in today’s competitive market. Arshon uses rapid prototyping techniques, which help clients get functional sensor modules quickly and iterate based on real-world testing.

- Compliance and Testing: Arshon Technology’s expertise ensures that sensors meet or exceed regulatory requirements. From EMC/EMI testing to specialized industry certifications, rigorous testing protocols are applied.

- Lifecycle Support: Once a sensor design is finalized, Arshon offers production support, component sourcing, and ongoing maintenance strategies to ensure long-term reliability and scalability.

Through this end-to-end service, Arshon helps bridge the gap between concept and a fully realized product, making sure the sensor fits seamlessly into the larger electronic ecosystem.

7. Conclusion

Sensors have truly revolutionized the field of modern electronic design. They bring products to life by enabling them to sense, adapt, and interact with the world around them. From simple consumer gadgets that adjust settings based on ambient light to complex industrial systems that monitor production lines in real-time, sensors are the backbone of innovation in countless industries.

However, integrating sensors successfully into electronic product development requires more than just selecting the right component; it calls for specialized knowledge of embedded systems, calibration methods, environmental conditions, and regulatory compliance. This is where sensor design services excel. By offering custom electronic design solutions tailored to the specific demands of different applications, firms like Arshon Technology ensure that sensor-enabled products achieve both high performance and reliability.

As industries continue to demand more accurate data, faster response times, and smarter automation, sensors will only become more central to how electronic systems operate. The benefits are immense—improved efficiency, enhanced user experience, reduced costs, and data-driven insights that can transform how businesses operate. Yet challenges remain, from power management and integration complexities to meeting rigorous regulatory standards.

In the final analysis, investing in high-quality sensor design services is no longer just an option for forward-thinking companies; it is a strategic necessity. By harnessing the capabilities of modern sensors, organizations can create cutting-edge products that stand out in a crowded market and pave the way for future breakthroughs in IoT, automation, healthcare, and beyond. Through careful planning, expert engineering, and a commitment to innovation, sensor design can turn ambitious concepts into industry-changing realities.