Printed Circuit Boards (PCBs) remain fundamental to modern electronics, functioning as the bedrock on which components like microcontrollers, capacitors, and connectors thrive. The backbone for these boards often involves FR4, a versatile glass-reinforced epoxy laminate widely recognized for its balanced mechanical, electrical, and thermal properties. Despite FR4’s popularity, certain specialized or high-performance applications may demand alternatives that closely match, or even surpass, FR4 in specific aspects. This leads us to the concept of “Pcb board material fr4 equivalent” solutions, bridging the gap between standard FR4 characteristics and unique performance criteria.

In this article, we’ll explore materials similar to FR4, investigate alternative multilayer PCB substrate material examples, and discuss how these “FR4 equivalents” can shape your next PCB design.

What Materials Are Similar to FR4?

Why FR4 Is so Popular

Before examining what materials are comparable or considered FR4 “equivalents,” it’s vital to understand why FR4 dominates the PCB landscape. FR4 is the industry workhorse for many reasons:

- Mechanical Strength: The glass-reinforced epoxy offers robust tensile and flexural strength, withstanding typical PCB manufacturing processes.

- Electrical Performance: FR4’s dielectric properties suffice for most low- to moderate-frequency applications, striking a good balance between cost and functionality.

- Thermal Stability: With a glass transition temperature (Tg) commonly around 130–150°C, it handles typical solder reflow cycles and moderate operational temperatures.

- Cost Efficiency: Mass production, standardization, and a well-established supply chain make FR4 cost-effective.

The Need for “FR4-Equivalent” Materials

Still, FR4 is not a universal solution for every PCB board material requirement. Certain advanced or niche applications demand better mechanical stability, higher Tg, improved dielectric properties, or superior thermal conductivity. Hence, designers often seek materials that are similar or roughly equivalent to FR4 in overall performance but supply unique characteristics needed by their specific application—commonly referred to as “FR4-like” or “FR4-equivalent” laminates.

Key Equivalence Criteria might include:

- Similar Tg: The glass transition temperature should remain in a comparable range.

- Comparable Dielectric Constant (Dk): Ensures that the board’s signal integrity and impedance match FR4-based designs.

- Process Compatibility: The material should adhere to standard PCB manufacturing steps, i.e., lamination processes, hole drilling, plating, etc.

- Mechanical Durability: Offers an equivalent or better mechanical strength to endure typical use environments.

Alternative Multilayer PCB Substrate Material Examples

Several materials serve as FR4 alternatives, each focusing on specific design parameters (thermal performance, frequency range, mechanical rigidity, or cost). Below are five categories of materials that can effectively act as “Pcb board material fr4 equivalent” solutions, depending on the application:

- Metal-core or metal-backed boards

- Ceramic substrates

- Composite Epoxy Material (CEM)

- High-frequency laminates

- Hybrid constructions with PTFE

We’ll examine each in detail.

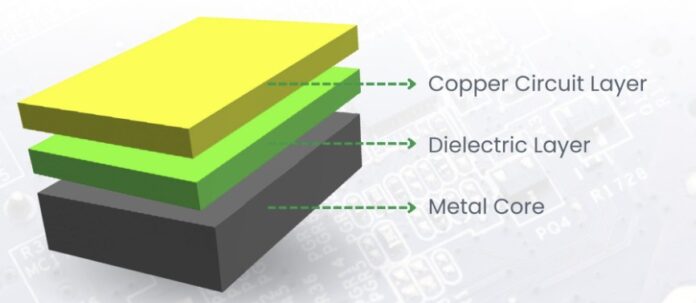

Metal-Core or Metal-Backed Boards

Metal-core or metal-backed PCBs are common in high-power or high-heat environments. They feature an aluminum or copper core at their base layer, improving heat dissipation substantially. While not a direct “FR4 equivalent” in mechanical sense, these boards can be similar to FR4 in manufacturing steps if the epoxy layer and copper foil layering remain standard. For a moderate jump in thermal performance, some metal-core substrates aim to mirror FR4 in terms of cost and processability.

Key Features:

- Enhanced Thermal Conductivity: Significantly outperforms FR4 in heat dissipation.

- Moderate Mechanical Strength: The metal core can be prone to bending or warping if extremely thin.

- Standard Processes: Usually support standard plating, drilling, and assembly with minimal modifications.

- Common Uses: LED lighting, power conversion systems, automotive lighting modules.

Advantages:

- Better heat management than FR4

- Durable, robust for power electronics

Drawbacks:

- Heavier weight due to metal core

- Potentially higher cost

- May have different expansion coefficients (CTE) that complicate multi-layer designs

Ceramics

Ceramic PCBs typically leverage materials like alumina (Al2O3), aluminum nitride (AlN), or beryllium oxide (BeO) to create boards with exceptional thermal conductivity, dimensional stability, and excellent high-frequency performance. However, the mechanical rigidity and brittleness differ from FR4. Despite these differences, certain ceramic PCBs can be considered FR4 “equivalents” for specialized high-temperature, high-reliability applications.

Key Features:

- Outstanding Thermal Conductivity: Minimizes temperature rise in high-power circuits.

- High-frequency Compatibility: Low dielectric loss at microwave or millimeter-wave signals.

- Dimensional Stability: Minimal expansion, maintaining shape under temperature stress.

Common Applications:

- RF power amplifiers

- LED substrates for industrial lighting

- Aerospace, defense electronics

Advantages:

- Superior thermal & high-frequency performance

- Minimal circuit drift over temperature cycles

Drawbacks:

- More fragile than FR4

- Higher fabrication cost

- Specialized manufacturing processes

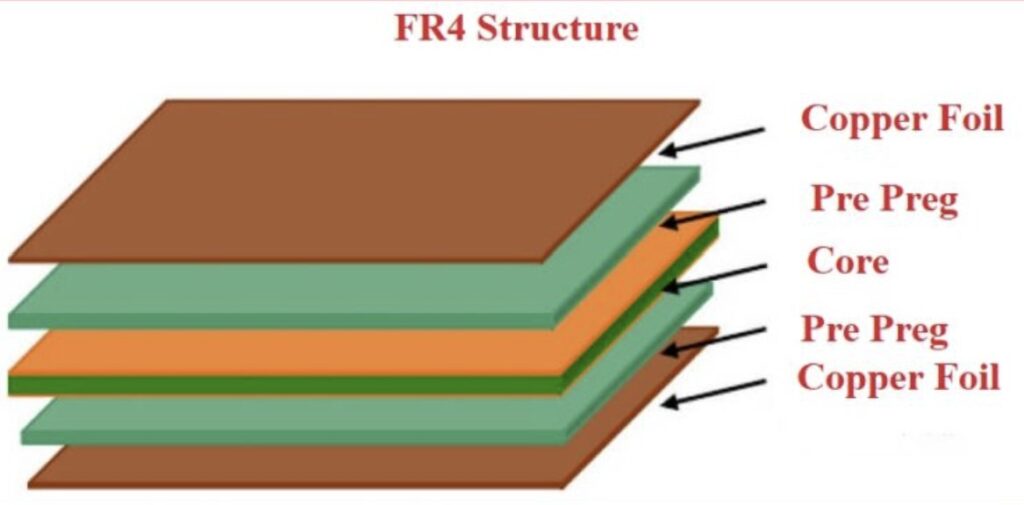

Composite Epoxy Material (CEM)

Composite Epoxy Material (CEM) boards, particularly CEM-1 and CEM-3, often appear in cost-sensitive applications. Composites typically involve woven glass fabric with an epoxy matrix, quite similar to FR4 in many ways.

- CEM-1: Paper-based with a single glass fiber layer, typically for single-sided boards.

- CEM-3: Glass cloth-based, akin to FR4, used for double-sided or multi-layer boards.

CEM materials can perform similarly to FR4 in mechanical and dielectric properties, though typically for lower-layer-count designs or moderate frequencies. They may cut costs by up to 10-30% compared to standard FR4.

Advantages:

- Cost savings

- Standard processing compatibility

- Good mechanical strength & decent thermal properties

Drawbacks:

- Slightly lower Tg, limiting high-temperature processes

- Not as widely used in complex, high-speed PCBs

- Not always available in thick multi-layer stacks

CEM-3, though, can be a near “FR4-equivalent,” making it an attractive material for consumer electronic boards that do not push frequency or temperature limits too heavily.

High Frequency Laminates

High-frequency laminates form a broad category encompassing materials designed for advanced RF or high-speed digital circuits. Leading brand examples include Rogers (e.g., Rogers 4000 or 3000 series), Taconic, Isola high-speed families, and so on.

While these laminates differ from FR4 in dielectric constant and loss tangent—often offering much better signal integrity at high frequencies—they can be considered “equivalent” in mechanical or manufacturing processes if the application needs them:

- Rogers 4350B: Slightly higher cost but better high-frequency performance than FR4, with fairly standard PCB manufacturing steps.

- Isola FR408HR: Improved dielectric properties yet similar mechanical properties to FR4.

- Taconic TLY or TLX**: Suitable for microwave frequencies, low loss, but can be integrated into standard line definitions in many shops.

Despite differences in cost, these high-frequency laminates sometimes slot in as an “FR4 stand-in” for advanced designs requiring minimal signal attenuation or stable dielectric performance.

Advantages:

- Low dielectric loss

- Stable Dk over wide temperature range

- Good mechanical strength

Drawbacks:

- Higher cost compared to FR4

- Sometimes narrower process windows

- Potential different copper peel strength or lamination requirements

Hybrid Construction with PTFE

Hybrid PCBs combine FR4 (or a close epoxy-based material) with PTFE-based dielectrics, creating a multi-layer board with certain layers dedicated to high-frequency or high-speed signals, and the rest built from more standard laminates. PTFE (Polytetrafluoroethylene) is known for extremely low dielectric loss, making it prized in microwave and RF circuits. Meanwhile, the FR4 portion or FR4-like materials are used for less critical or lower-speed sections, balancing cost.

Key Features:

- Mixed Stack-up: Some layers are PTFE-based, while others remain epoxy-based for cost and mechanical reasons.

- Thermal Expansion Management: More advanced materials also help handle the mismatch in CTE between PTFE and epoxy, ensuring reliability.

- Selective Performance: Only the essential RF layers see high-performance PTFE laminates.

Advantages:

- Targeted performance for high-frequency lines

- Potential cost savings over full PTFE usage

- Normal FR4 (or CEM) layers for simpler circuit blocks

Drawbacks:

- More complicated lamination

- Potential cost or supply chain complexities

- Tighter manufacturing tolerances

Though not purely FR4, these hybrids still might classify as “FR4 equivalents” in large sections of the board, featuring advanced layers only where needed.

How Do These Materials Compare to Standard FR4?

Thermal Stability: Many FR4 alternatives focus on higher Tg values, better conduction, or improved mechanical stability at elevated temperature.

Dielectric Characteristics: For high-frequency or minimal signal loss, specialized laminates (e.g., PTFE-based, ceramic-based) outshine FR4.

Mechanical Robustness: FR4 remains robust enough for everyday consumer and industrial electronics; alternatives like metal-core or ceramic boards may handle unique mechanical or thermal demands.

Manufacturing Process: Some FR4 “equivalents” use standard FR4-like processes (CEM-3, certain high-speed laminates), while others (ceramics, PTFE) call for specialized equipment or processing knowledge.

Cost: Generally, true FR4 remains cost-effective. Alternatives typically add cost but can yield large performance benefits, making them cost-effective in the right use cases.

Relevance to PCB Design, Board Material, and FR4

When designing a PCB, selecting the board material is a foundational decision. Many PCB engineers default to FR4 for all but the most demanding designs. However, it’s crucial to acknowledge “FR4 equivalents” exist—ranging from CEM-3 for simple cost-driven designs to specialized ceramic or PTFE-based materials for advanced, high-frequency, or high-temperature scenarios. This selection influences:

- Signal Integrity: Materials with stable dielectric constants and minimal losses can handle higher bandwidth signals.

- Thermal Management: Metal-cores or advanced ceramics can better dissipate heat from high-power components.

- Reliability: Some designs require minimal expansion or mechanical stress, making a more stable epoxy or ceramic necessary.

- Manufacturing Complexity: A near-fr4 substrate often supports standard drilling, plating, and lamination equipment. More exotic materials require specialized processes, possibly limiting manufacturing vendor choices.

Summary of Pcb Board Material FR4 Equivalent Options

- Metal-core or metal-backed: Focus on heat dissipation, partially overlapping FR4’s mechanical/chemical properties in easier prototyping or mass production than specialized ceramics, but with heavier weight.

- Ceramics: Extreme thermal and frequency performance; cost and brittleness hamper everyday usage.

- CEM: Cost-friendly, near-FR4 mechanical/electrical performance, especially in consumer or low-layer count boards.

- High-frequency laminates: Superior to FR4 in high-speed design, used extensively in networking, telecom, and 5G boards.

- Hybrid PTFE: Balanced approach mixing FR4 with PTFE for selective high-frequency or low-loss demands.

Conclusion

A standard FR4 substrate may work for many PCB designs, but advanced or specialized applications require stepping outside of that comfort zone—exploring the wide realm of “Pcb board material fr4 equivalent” materials. Whether you’re optimizing for cost, mechanical endurance, signal integrity, or thermal management, these alternatives open a world of possibilities. By carefully evaluating each material’s pros and cons, you can achieve an optimal synergy of performance and budget.

Key takeaways:

- FR4 equivalents can maintain similar mechanical and electrical fundamentals but add specialized features—like higher Tg, improved thermal conduction, or lower dielectric loss.

- Materials like CEM-3 can closely replicate FR4 performance at a slightly lower cost, while high-frequency laminates or ceramics can surpass it in advanced or specialized tasks.

- Hybrid solutions combine cost-effectiveness of FR4 with specialized laminates where necessary, offering the best of both worlds for complex multi-layer or high-speed designs.

Ultimately, selecting the best “FR4 equivalent” requires understanding your design’s frequency, heat, mechanical, and budget targets. Partnering with a capable PCB manufacturer or design house ensures proper handling of these advanced materials, from stack-up planning through production—leading to consistently high-quality results in your finished boards.