In modern electronics manufacturing, the integration of advanced soldering methods is vital for achieving high-quality and reliable products. Every stage of production, from pcb design to final assembly, demands careful attention to soldering processes to guarantee performance and durability. Advanced solder techniques such as Surface Mount Technology (SMT), reflow soldering, wave soldering, and selective soldering have revolutionized how circuit boards are fabricated, enabling faster production, smaller components, and improved consistency.

SMT Assembly Services

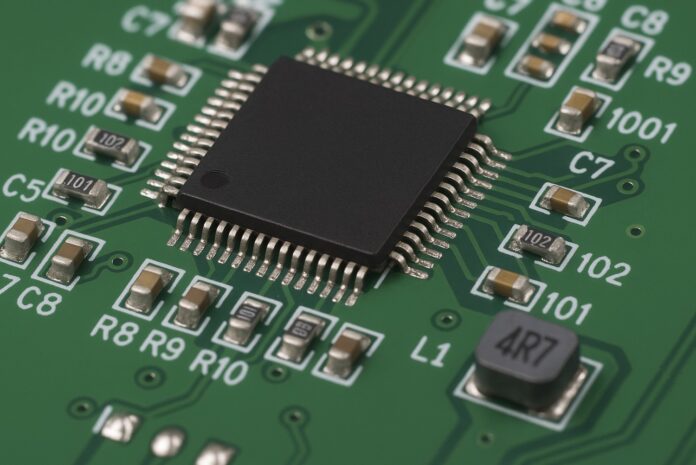

Surface Mount Technology (SMT) has become the standard for most electronic assemblies. It allows components to be placed directly onto the surface of a printed circuit board without the need for through-hole leads. SMT assembly services use automated pick-and-place machines that can position thousands of components per hour with remarkable precision. This automation not only reduces labor costs but also enhances accuracy and repeatability.

SMT assembly starts with stencil printing, where solder paste is applied to the pads of the PCB. The solder paste composition is critical; it contains flux and microscopic solder particles that melt during the reflow process. Once applied, the board passes through the pick-and-place station, where tiny resistors, capacitors, and ICs are mounted in exact positions. After placement, the board proceeds to the reflow soldering stage for permanent bonding.

The use of SMT has transformed modern electronics by allowing higher circuit density, lighter assemblies, and faster production cycles. SMT is suitable for consumer electronics, automotive systems, industrial controls, and aerospace electronics, where reliability and precision are key.

Reflow Soldering Process

Reflow soldering is the backbone of SMT assembly. After components are placed on the solder paste, the PCB enters a reflow oven where controlled heat melts the solder particles, forming electrical and mechanical joints. The process typically involves several stages: preheat, soak, reflow, and cooling.

During preheat, the board and components are gradually brought up to temperature to prevent thermal shock. The soak phase stabilizes the temperature across the board and activates the flux, which cleans the metal surfaces. The reflow stage reaches peak temperature, allowing the solder to melt and wet the component leads and pads. Finally, the board is cooled in a controlled manner to solidify the joints.

The quality of the reflow profile determines the integrity of the solder joints. Too high or too low a peak temperature can cause solder defects such as tombstoning, cold joints, or bridging. Engineers use thermal profiling tools to record the exact temperature of various points on the PCB to fine-tune the reflow oven settings. This optimization is essential for consistent solder quality, especially when dealing with mixed-technology boards or lead-free alloys.

Wave Solder vs Reflow

Wave soldering and reflow soldering are two distinct processes suited for different component types. While reflow soldering is ideal for SMT components, wave soldering remains relevant for through-hole components.

In wave soldering, the PCB passes over a molten wave of solder. The process involves applying flux to clean and prepare the metal surfaces, preheating the board, and then running it across the solder wave. The molten solder adheres to exposed metal leads, creating strong joints as it cools. This method is fast and effective for through-hole assemblies, where multiple joints can be soldered simultaneously.

However, wave soldering is not suitable for fine-pitch SMT components due to the risk of solder bridging. Reflow soldering, on the other hand, offers precise temperature control and is compatible with miniature and surface-mounted parts. In modern mixed-technology assemblies, both techniques may be used in combination: reflow soldering for SMT components and wave or selective soldering for through-hole components.

Selective Solder Advantages

Selective soldering provides a targeted alternative to traditional wave soldering for through-hole components on mixed-technology boards. Using programmable nozzles or mini-waves, selective soldering machines can apply molten solder only where needed, without exposing the entire board to heat.

The main advantages of selective soldering include reduced thermal stress on sensitive SMT components, improved joint quality, and the ability to handle densely populated boards. Selective soldering is highly programmable, enabling precise control over dwell time, temperature, and solder flow. This flexibility allows manufacturers to optimize soldering parameters for each component type and location, enhancing reliability and yield.

This method is particularly valuable for high-mix, low-volume production where manual soldering would be too labor-intensive and inconsistent. Automated selective soldering ensures repeatability and minimizes operator dependency.

Soldering Technologies Comparison

Each soldering technique—SMT reflow, wave, and selective—has its own applications, benefits, and limitations. Reflow soldering is preferred for SMT components due to its precision and compatibility with automated production lines. Wave soldering remains valuable for traditional through-hole boards and large-scale production. Selective soldering bridges the gap, providing an efficient way to integrate both SMT and through-hole components on the same assembly.

| Technique | Best for | Advantages | Limitations |

|---|---|---|---|

| Reflow Soldering | SMT Components | Precise, clean joints, suitable for automation | Not ideal for through-hole |

| Wave Soldering | Through-hole Assemblies | Fast for high volume | Thermal stress, less precision |

| Selective Soldering | Mixed-technology Boards | Targeted heat, high reliability | Slower for large volume |

Choosing the right method depends on the pcb design, component mix, and production volume. Many manufacturers use hybrid processes to balance speed and quality.

Automated Solder Machines

Automation is central to modern electronics assembly. Automated soldering machines, whether for reflow ovens, wave solder systems, or selective soldering units, bring consistency, repeatability, and efficiency to the process. These machines precisely control parameters like temperature gradients, solder wave height, conveyor speed, and flux application.

In high-volume manufacturing, robotic arms and vision systems perform soldering tasks with micrometer-level accuracy. Advanced software integration allows engineers to monitor performance, record process data, and implement closed-loop feedback systems for quality control.

Automation reduces human error and improves productivity, making it possible to produce complex, high-density boards with minimal manual intervention. In industries such as aerospace, automotive, and telecommunications, automated soldering is a prerequisite for maintaining stringent quality standards.

Solder Paste Reflow Profile

A well-designed solder paste reflow profile is crucial for achieving strong, reliable solder joints. The reflow profile defines the temperature over time as the board passes through the oven. It typically consists of four stages: preheat, soak, reflow, and cooling.

- Preheat: Gradual warming to activate flux and prevent thermal shock.

- Soak: Stabilization phase to remove volatiles and ensure uniform temperature.

- Reflow: The actual melting of solder, forming metallurgical bonds.

- Cooling: Controlled cooling to solidify joints and prevent defects.

Each solder alloy requires a specific temperature curve, and deviations can lead to solder defects. Engineers use thermal profiling tools to fine-tune oven zones based on board thickness, component mass, and solder type. Proper reflow control is especially important in lead-free processes, where the melting point is higher and thermal margins are narrower.

Mixed-Technology Assembly

Many electronic assemblies combine SMT and through-hole components, leading to what is known as mixed-technology assembly. This approach allows designers to use the most suitable component types for each function. For example, power connectors may still require through-hole mounting for mechanical strength, while control ICs and sensors use SMT.

In mixed-technology assembly, the challenge lies in optimizing soldering processes so both component types achieve proper bonding. Often, SMT components are reflow soldered first, followed by wave or selective soldering for through-hole parts. Advanced pcb design strategies—such as component layout planning, thermal isolation, and solder mask definition—help facilitate dual-process soldering without compromising quality.

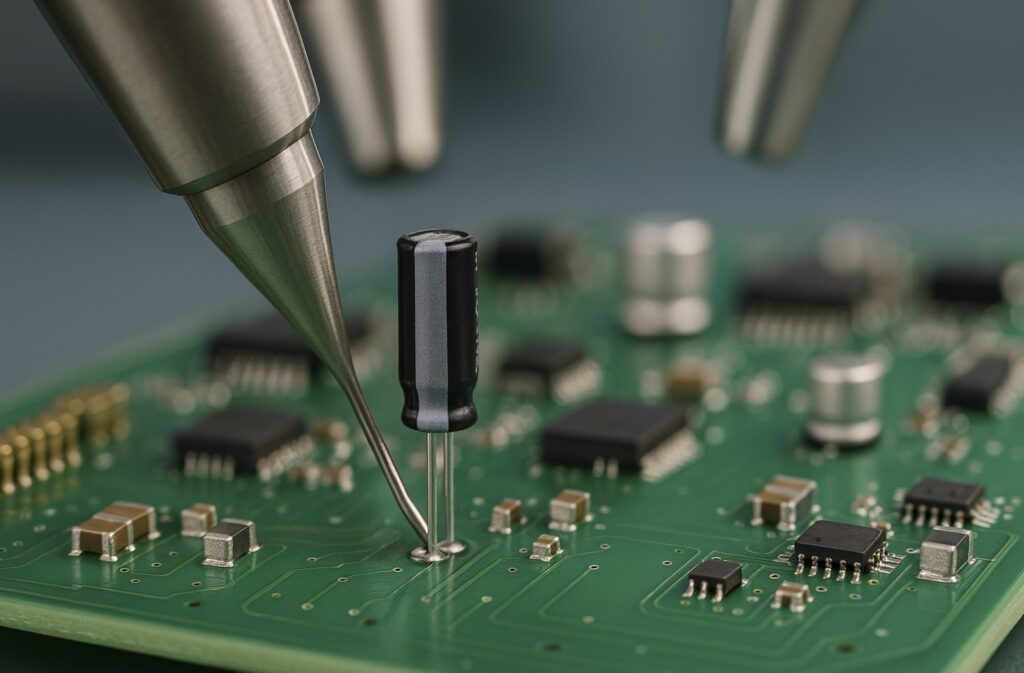

Through-Hole Soldering

Through-hole soldering remains relevant for components that require strong mechanical attachment, such as connectors, transformers, and high-current devices. In automated lines, through-hole components are typically soldered using wave or selective soldering machines, though manual soldering is still used for prototypes or repairs.

The through-hole process involves inserting leads into plated holes and soldering them from the underside of the PCB. Proper hole size, plating thickness, and solder volume are essential to form reliable connections. For high-reliability applications, such as aerospace or medical electronics, inspection techniques like X-ray imaging and cross-section analysis are used to verify solder joint quality.

Lead-Free Soldering Methods

With global environmental regulations such as RoHS (Restriction of Hazardous Substances), lead-free soldering has become the standard. Lead-free alloys, often based on tin-silver-copper (SAC), offer good mechanical strength and reliability but require higher process temperatures compared to traditional tin-lead solders.

Manufacturers have adapted by upgrading reflow ovens and wave solder systems to handle higher thermal loads. Flux formulations and solder pastes have also evolved to minimize oxidation and improve wetting behavior. Lead-free soldering presents new challenges such as increased dross formation and potential for brittle joints, but with careful process optimization, these issues can be controlled.

Modern lead-free methods include nitrogen-assisted reflow, which minimizes oxidation, and vapor-phase soldering, which provides uniform heat distribution. These advancements continue to push the boundaries of quality and environmental responsibility.

Conclusion

Advanced solder techniques form the foundation of modern electronics manufacturing. Whether it’s SMT reflow, wave soldering, or selective soldering, each method plays a vital role in achieving reliability and performance. With the integration of automation, lead-free processes, and mixed-technology strategies, manufacturers can produce compact, durable, and environmentally responsible products.

As pcb design continues to evolve toward higher density and miniaturization, mastering these soldering techniques becomes increasingly important. Future innovations, such as AI-driven process control and adaptive thermal management, will further enhance soldering precision, making electronics production faster, cleaner, and more efficient.