As technology evolves, older devices and systems often struggle to meet modern expectations for performance, efficiency, and connectivity. Companies facing component obsolescence, high production costs, or outdated designs must look toward Upgrading and Redesigning Existing Electronic Products as a strategic solution. From advanced pcb design techniques to hardware re-engineering and firmware modernization, the goal is to improve functionality, manufacturability, and reliability while reducing costs and extending product life.

Product Upgrade Services

Product upgrade services help manufacturers transform outdated devices into high-performing, market-ready solutions. These upgrades can include hardware replacements, firmware optimization, communication module integration, and compliance updates. With technology advancing at a rapid pace, upgrading products allows companies to maintain competitiveness without starting from scratch.

A typical product upgrade begins with an in-depth analysis of the current design. Engineers assess performance metrics, identify bottlenecks, and evaluate aging components. Based on these findings, they create a roadmap outlining which elements to modify or replace. Upgrades might involve introducing faster microcontrollers, new wireless connectivity (Bluetooth, Wi-Fi, or LoRa), or improved power management circuits.

In industrial, medical, and automotive markets, product upgrade services often include compliance updates to meet new safety or environmental regulations, such as RoHS, REACH, or ISO standards. By updating both hardware and software elements, manufacturers can breathe new life into legacy systems and maintain a strong presence in competitive markets.

Legacy Hardware Redesign

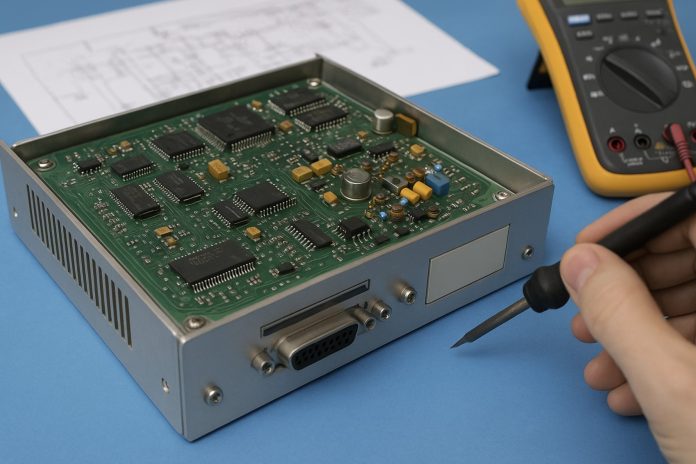

Legacy hardware redesign is an essential step in bringing old products up to modern standards. Over time, many components become obsolete, and the original suppliers may no longer support them. Redesigning legacy hardware involves re-engineering the existing boards, updating schematics, and adapting the design to new component footprints.

In the process, engineers focus on improving circuit efficiency, thermal management, and signal integrity. By applying modern pcb design practices such as impedance control, multilayer routing, and EMI mitigation, redesigned boards perform better and last longer.

One of the main challenges of legacy redesign is maintaining backward compatibility. Customers who depend on older devices often require new models that interface seamlessly with existing systems. Therefore, engineers must preserve critical I/O interfaces and communication protocols while upgrading internal electronics.

The result is a product that maintains its original functionality but benefits from faster performance, improved reliability, and lower power consumption—all while meeting today’s manufacturing and compliance requirements.

PCB Redesign Services

As the foundation of every electronic product, the printed circuit board (PCB) plays a central role in performance, cost, and durability. PCB redesign services allow companies to modernize their hardware, optimize layouts, and incorporate new technologies without completely re-engineering the product.

Engineers start by reviewing the existing PCB to identify limitations such as signal crosstalk, insufficient copper thickness, or inefficient component placement. Using advanced design tools, they recreate the schematic and layout, introducing modern components and refining trace geometry for better signal flow.

When products transition from through-hole to surface-mount technology (SMT), redesign services are critical. SMT reduces board size, lowers production costs, and supports automation. For high-speed digital or RF designs, engineers may also introduce impedance-controlled routing and ground planes to minimize noise and improve stability.

Another key aspect of PCB redesign is preparing the design for Design for Manufacturability (DFM) and Design for Testability (DFT) standards. These enhancements streamline assembly and testing, reducing defects and improving production yield.

Product Refresh Program

A product refresh program extends a product’s lifecycle while adding new features and improvements. Instead of retiring a successful product, manufacturers can use refresh programs to modernize the design and reintroduce it to the market.

Product refreshes typically include aesthetic improvements, performance upgrades, and user interface modernization. For example, an industrial control unit may gain a touchscreen display, energy-efficient power supplies, or enhanced communication capabilities.

Software updates and IoT integration are often part of the refresh process, allowing older devices to connect with cloud platforms or monitoring systems. Refresh programs are also ideal for meeting new environmental standards or improving energy efficiency.

By leveraging existing tooling, certifications, and supply chains, product refresh programs minimize development costs and accelerate time-to-market. They provide a bridge between legacy technology and next-generation innovation, helping manufacturers remain relevant in fast-changing industries.

Re-Engineering Electronic Devices

Re-engineering electronic devices involves rethinking and reconstructing existing products to achieve better performance, functionality, or manufacturability. It is a multidisciplinary effort that integrates hardware redesign, firmware optimization, and mechanical refinement.

In many cases, re-engineering starts with a teardown of the existing device to assess design weaknesses and production inefficiencies. Engineers use tools such as 3D scanning, circuit reverse-engineering, and thermal imaging to analyze and improve every subsystem.

The process may involve migrating from analog to digital control, upgrading to new microcontrollers, or improving connectivity with Bluetooth Low Energy (BLE), LoRaWAN, or cellular modules. Engineers also redesign power systems for improved energy efficiency and thermal stability, ensuring compliance with modern EMC and safety regulations.

The ultimate goal of re-engineering is not just modernization—it is to enhance performance while simplifying assembly and reducing costs. Manufacturers that invest in re-engineering gain a significant advantage through improved quality, reduced field failures, and better scalability for future models.

Cost-Effective Product Upgrade

A cost-effective product upgrade strikes the right balance between investment and improvement. Instead of complete redevelopment, targeted upgrades address critical performance gaps while maintaining most of the existing design and infrastructure.

The process begins with a cost-benefit analysis to prioritize which changes deliver the greatest return on investment. For example, replacing a legacy processor with a newer version might unlock faster data processing without altering the PCB layout. Similarly, introducing modular components allows easy upgrades in the future without major redesign.

Manufacturers can also reduce costs by consolidating multiple boards into a single assembly, minimizing part counts, and replacing custom components with standard, easily sourced alternatives.

Outsourcing redesign and testing to specialized engineering firms further reduces overhead. These firms bring deep expertise in pcb design, compliance testing, and manufacturing optimization—allowing companies to achieve better results faster and at lower cost.

Redesign for Manufacturability

Even the best electronic design can fail if it is difficult or expensive to produce. Redesign for manufacturability (DFM) focuses on simplifying the design and production process to improve yield and reduce assembly costs.

Engineers review every aspect of the product—from PCB layout to mechanical housing—to identify areas that can be optimized. For example, replacing hand-soldered connectors with surface-mount types can reduce labor time. Standardizing components across multiple products simplifies inventory management and supplier negotiations.

Design teams also evaluate tolerance stacks, assembly sequences, and automated test accessibility. By planning for manufacturability early in the redesign phase, companies can eliminate costly rework, shorten lead times, and improve overall production efficiency.

This approach not only reduces cost but also increases reliability. Simplified designs have fewer assembly errors and better long-term serviceability, which enhances brand reputation and customer satisfaction.

Obsolete Component Replacement

Obsolete component replacement is one of the most common challenges in upgrading older products. Semiconductor manufacturers regularly discontinue parts, leaving companies scrambling to find equivalents. Replacing obsolete components requires careful consideration of electrical compatibility, footprint differences, and long-term availability.

When direct replacements are unavailable, engineers redesign circuits to accommodate newer or alternative components. This often involves updating firmware to match new device specifications. Simulation tools are used to validate signal integrity and performance before production.

In some cases, component replacement leads to broader system upgrades, as new components can introduce added functionality such as higher processing power or enhanced power efficiency. For example, a microcontroller replacement might enable additional communication interfaces, expanding product capabilities.

Proactive obsolescence management is key to maintaining production continuity. Establishing a lifecycle management plan and maintaining close communication with suppliers helps manufacturers anticipate obsolescence before it becomes disruptive.

Enhancing Legacy Systems

Enhancing legacy systems allows companies to extend the value of their existing product lines without sacrificing reliability or compatibility. This strategy is particularly valuable for industries such as defense, transportation, and industrial automation, where long-term product support is critical.

Enhancements can range from simple firmware updates to complete subsystem overhauls. Engineers often add modern interfaces such as Ethernet, USB, or wireless modules to replace outdated serial connections. Display technologies can be upgraded from monochrome LCDs to high-resolution color touchscreens.

In industrial control systems, adding predictive maintenance capabilities through sensor integration or cloud analytics dramatically improves operational efficiency. Firmware optimization enhances processing speed, reduces power consumption, and strengthens cybersecurity.

By combining hardware and software enhancements, companies can maintain continuity for their customers while providing new value through improved performance and connectivity.

Electronics Modernization

Electronics modernization represents the holistic transformation of older products into modern, high-performance systems. It integrates all aspects of hardware, software, and mechanical design to achieve cutting-edge functionality with minimal disruption to existing workflows.

Modernization often includes transitioning to contemporary architectures, such as replacing 8-bit controllers with 32-bit microprocessors or upgrading analog circuits with digital control systems. Engineers also introduce low-power components and optimized pcb layouts to meet energy efficiency standards.

Mechanical modernization can include lighter materials, smaller enclosures, and better thermal management. Meanwhile, firmware upgrades add compatibility with current communication protocols and user interfaces.

In industries such as medical devices, modernization also helps maintain regulatory compliance. Updated electronics meet current ISO, IEC, or FDA requirements, ensuring ongoing certification and market access.

Modernization projects not only revive aging products but also position companies to compete effectively in future markets by integrating AI-ready sensors, IoT connectivity, and data analytics capabilities.

The Benefits of Redesign and Modernization

Upgrading and redesigning existing products deliver numerous benefits beyond technical improvements. Manufacturers gain:

- Extended product lifecycle, reducing the need for full redevelopment.

- Reduced manufacturing costs through simplified design and part standardization.

- Improved reliability via modern components and better testing.

- Faster time-to-market compared to developing new products from scratch.

- Regulatory compliance with updated global standards.

These improvements translate directly into greater profitability, stronger customer loyalty, and a sustainable competitive edge.

Conclusion

Upgrading and Redesigning Existing Electronic Products is not merely a maintenance task—it is a strategic approach to innovation and longevity. By combining modern pcb design, component upgrades, and firmware enhancements, companies can transform outdated devices into reliable, future-ready solutions.

Through legacy hardware redesign, cost-effective upgrades, and manufacturability improvements, manufacturers enhance performance, extend product life, and maintain compliance in an ever-evolving technological landscape. In a world where speed and reliability define success, upgrading existing electronic products is the key to staying ahead while maximizing the value of every design.