Wounds are a ubiquitous part of the human experience, yet for many people they represent far more than a minor inconvenience. While most cuts and scrapes heal relatively quickly, certain conditions—such as diabetes, compromised immune systems, and chronic infections—can transform a minor injury into a persistent, debilitating wound. These chronic wounds can last for weeks, months, or even years, leading to increased healthcare costs, heightened anxiety, depression, and potentially life-threatening complications. According to various estimates, the financial burden of caring for chronic wounds reaches billions of dollars per year worldwide. As populations continue to age and the prevalence of conditions like diabetes grows, effective wound-care solutions have never been more urgent. Enter the concept of a “smart bandage,” a cutting-edge blend of traditional bandaging materials and tiny electronic components designed to monitor, report on, and even help manage the wound-healing process in real time. The integration of advanced PCB design is pivotal in this innovation, allowing for the development of compact electronic systems that enhance the smart bandage’s capabilities.

The Challenge of Chronic Wounds

Chronic wounds are defined as injuries that do not progress through the normal healing stages in a predictable amount of time. They persist for more than 12 weeks and often show minimal signs of improvement despite ongoing treatment. People who suffer from chronic wounds commonly cope with more than physical pain; they can experience significant emotional distress due to the protracted healing process, the unpleasant odor of some wounds, the need for frequent bandage changes, and the potential for social isolation. Meanwhile, healthcare professionals strive to manage infection risk, prevent further tissue damage, and create optimal conditions for healing—an often complex and resource-intensive task.

Diseases like diabetes further complicate wound care. Chronically high blood sugar impairs blood circulation and dampens the immune response, making it harder for wounds to close. Nerve damage, or neuropathy, can also occur, dulling the sensation of pain and leaving patients less aware of injuries that worsen over time. Additionally, suppressed immune systems—whether from underlying medical conditions, certain medications, or advanced age—further compound the risk of infection. When these factors converge, the healing process stalls, resulting in wounds that seem to linger indefinitely.

Because of these complexities, the cost of chronic wound care is enormous. Between specialized dressings, repeated clinic visits, hospitalizations for wound-related infections, and lost productivity due to disability, the toll on patients and healthcare systems can skyrocket. It is no surprise that medical research has turned to innovative solutions, like the integration of electronics with wound dressings, to reduce costs, minimize suffering, and help patients regain their quality of life.

Imagining the Smart Bandage

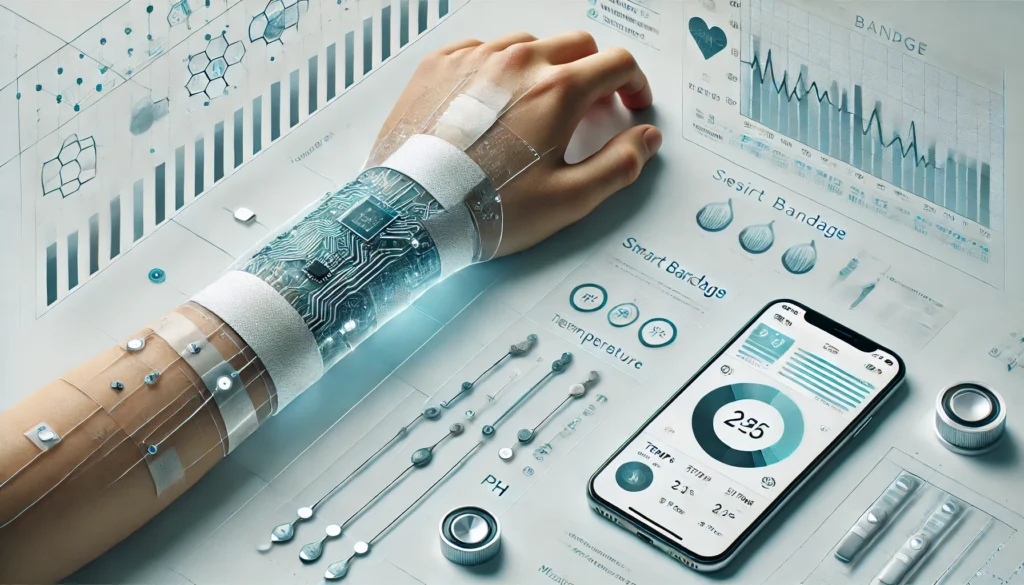

A smart bandage preserves the key features of a standard dressing—protecting the injury from dirt and microbes—while incorporating a suite of embedded electronic sensors that monitor the wound’s status. The device relies on a form factor similar to an adhesive bandage but comes equipped with a flexible, printable circuit board (PCB). These advanced PCBs must be designed to stretch, twist, and bend without losing functionality, making flexible PCB design one of the most important innovations enabling comfortable, continuous use.

Inside this miniature electronic platform are sensors capable of measuring parameters such as electrical conductivity, impedance, and pH levels in the wound exudate (the fluid that seeps from an injury). Shifts in pH might signal an infection, while changes in electrical conductivity could indicate tissue regrowth or necrosis. Sensors can also detect bleeding or changing moisture levels, providing valuable information about the state of the wound and whether the dressing might adhere improperly when removed.

The Role of PCB Design in Smart Bandages

One of the biggest hurdles in creating a functional smart bandage is ensuring that the integrated electronics work reliably under the constant motion of daily life. Enter PCB design—particularly the specialized craft of flexible PCB design. This involves selecting materials, layouts, and production techniques that yield circuits with high durability, low power consumption, and consistent signal quality.

A leading force in this domain is Arshon Technology, a company with significant expertise in flexible PCB design and advanced manufacturing solutions. By leveraging novel materials and engineering strategies, Arshon Technology develops circuit boards that maintain reliable performance even when bent or twisted. This adaptability is critical for medical devices designed to conform to the body and remain comfortably in place during regular activity. Through collaborations with medical researchers and device manufacturers, Arshon Technology is helping to bring next-generation wearable devices—like smart bandages—to market.

How Smart Bandages Work

From a technological standpoint, the smart bandage employs several types of measurements to gain a comprehensive view of the wound:

Conductivity Measurements

Electrodes near the wound area measure electrical signals tied to tissue regrowth or deterioration. Subtle variations in conductivity can alert patients and healthcare professionals to improvements or escalating problems.

Impedance Sensing

Impedance, or the resistance to electrical current, differs between healthy and compromised tissue. By monitoring these shifts, the system can detect early signs of infection or delayed healing.

pH Monitoring

The acidity or alkalinity of wound exudate strongly correlates with healing progress. Elevated pH levels often point to bacterial growth, while more neutral levels can signal healthful conditions.

Temperature and Moisture Levels

Some designs incorporate sensors for temperature and moisture, since a spike in temperature can indicate infection, while moisture levels can guide optimal dressing changes.

All collected data is transmitted via Bluetooth Low Energy (BLE) to a smartphone app. Through specialized algorithms, the app interprets real-time information on wound status. Should readings suggest a looming infection or compromised circulation, the patient receives an alert and is advised to seek medical care. On the other hand, signs of steady healing can help alleviate anxiety by showing tangible progress.

A Smartphone App for Precision Care

The smartphone application serves as the digital nerve center for a smart bandage system. It receives raw sensor data from the bandage and translates it into meaningful insights:

- Immediate Alerts

When an abnormal pH level or sudden temperature increase suggests infection, the app notifies the patient. It can also remind them about medication schedules or provide step-by-step guidance on cleaning the wound. - Progress Tracking

Graphic visualizations help patients and doctors see trends over time, allowing them to assess the effectiveness of treatments and bandage choices. This tangible feedback can be especially reassuring for those managing long-term wounds. - Customized Care Plans

Since sensor data is updated continuously, healthcare professionals can tailor care strategies more accurately. Adjusting antibiotic use, recommending a new dressing type, or scheduling a telemedicine visit can all be prompted by real-time feedback from the smart bandage. - Data Sharing

With the patient’s permission, the app can forward wound data to clinicians. This enables remote monitoring of chronic wounds, reserving in-person visits for when red flags arise and saving time and costs for both patient and provider.

Advantages for Patients and Healthcare Systems

Smart bandages have the potential to elevate wound care from a reactive process to a proactive, personalized experience. Real-time data collection and alerts can help patients act early to prevent infections from escalating, thus avoiding emergency room trips, advanced procedures, or lengthy hospital stays. This stands to trim the considerable costs tied to chronic wound care and improve patient outcomes by catching complications early.

By integrating telemedicine features, the smart bandage concept also lightens the load on healthcare professionals. Clinicians can monitor multiple patients remotely and prioritize those displaying critical readings. The result is more efficient resource allocation, alleviating pressure on overburdened healthcare facilities. Patients, meanwhile, benefit from fewer clinic visits, which can reduce stress and, for those with limited mobility, remove significant travel barriers.

For individuals battling the psychological toll of a wound that refuses to heal, a smart bandage can restore a sense of control. Seeing small, measurable improvements fosters hope, while prompt notifications about potential complications provide reassurance that the problem will be caught early. This balance of real-time monitoring and patient empowerment could be a game-changer for those grappling with anxiety or depression tied to long-standing injuries.

The Future of Smart Bandages

While still a relatively new innovation, research and development in smart bandages is moving quickly. The miniaturization of electronics, the growing sophistication of flexible PCB design, and advances in battery technology have set the stage for revolutionary strides in wound management. Some endeavors even explore releasing therapeutic agents—like antimicrobial compounds—directly from the bandage in response to sensor readings, initiating preemptive treatment the moment conditions suggest an imminent infection.

Despite the promise, several challenges loom. High manufacturing costs, regulatory requirements, and ensuring robust data security are hurdles to large-scale adoption. Yet, the direction is clear: the marriage of medical science, materials engineering, and digital technology is forging a new path in wound care.

Companies like Arshon Technology, with deep expertise in PCB design and a commitment to quality engineering, are central to bringing these advanced medical devices to life. By partnering with innovators in healthcare, they help translate imaginative concepts into working prototypes that can be rigorously tested, refined, and ultimately deployed in real-world clinical settings.

Conclusion

The quest to improve patient outcomes and contain the escalating costs of chronic wound management has led to the advent of the smart bandage—an inventive blend of conventional dressings and next-generation electronic sensors. Through embedded conductivity, impedance, and pH monitoring, along with the support of smartphone apps, these dressings can spot trouble before it escalates and reassure patients when healing is on track.

Although obstacles remain in manufacturing, regulation, and implementation, the potential benefits are profound. A world where chronic wounds heal faster, where patients gain emotional relief from real-time feedback, and where clinicians can intervene swiftly and accurately is rapidly approaching. With the support of leaders in flexible PCB design like Arshon Technology, these once-futuristic ideas are quickly transforming into tangible solutions—offering hope, relief, and a more efficient healthcare experience for patients who have long struggled with wounds that resist healing.