Autonomous vehicles (AVs) are at the forefront of technological advancement, revolutionizing transportation through self-driving capabilities that enhance safety, efficiency, and comfort. Behind the innovative technology of autonomous vehicles lies intricate and robust printed circuit board (PCB) design. This extensive article explores the detailed considerations necessary for effective PCB design specifically tailored for autonomous vehicles, thoroughly addressing safety and reliability, material selection, data transmission, EMI/EMC considerations, and real-world case studies.

Autonomous Vehicles

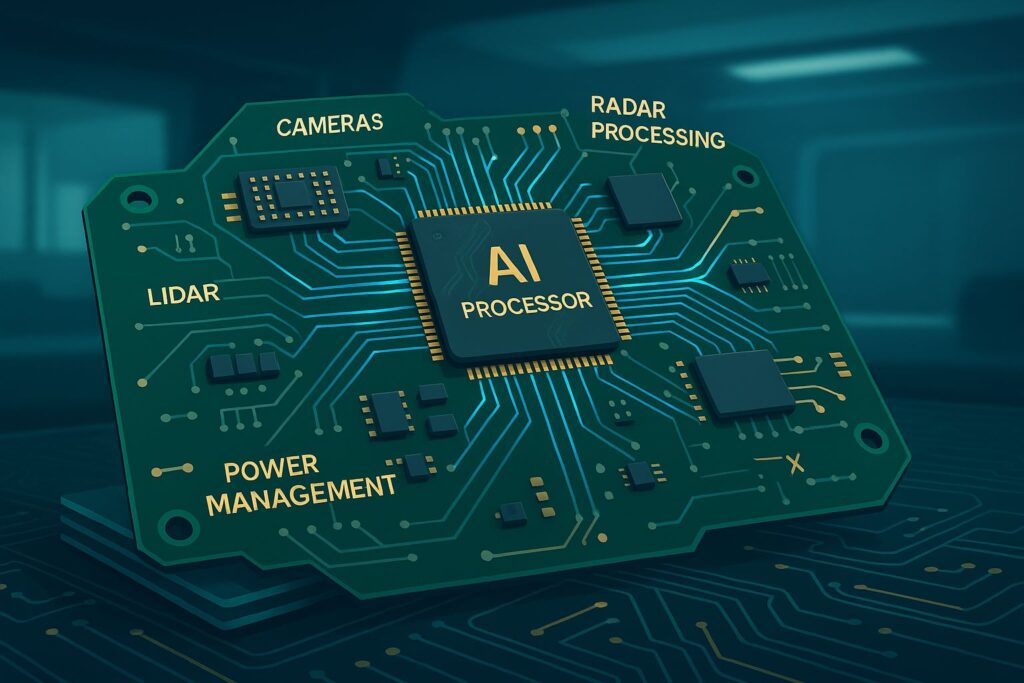

Autonomous vehicles are transforming modern transportation through sophisticated integration of technologies such as sensor fusion, artificial intelligence (AI), and advanced computing systems. These vehicles continuously analyze real-time data from diverse sensors—including lidar, radar, ultrasonic sensors, and cameras—to autonomously navigate their surroundings safely and effectively. Key systems integral to autonomous vehicles include:

- Sensors: High-resolution sensors that capture critical environmental data.

- Computational Units: Powerful processors capable of handling extensive data analysis rapidly and reliably.

- Communication Systems: Advanced vehicle-to-everything (V2X) communications enabling interactions with other vehicles and infrastructures.

- Power Management: Systems that efficiently manage energy consumption, crucial for electric and hybrid autonomous vehicles.

Safety and Reliability

Safety and reliability are paramount in autonomous vehicle applications. PCBs in autonomous vehicles must adhere to stringent automotive standards, notably ISO 26262, which dictates comprehensive functional safety requirements.

Functional Safety (ISO 26262)

ISO 26262 standardizes safety procedures across automotive electronics, emphasizing:

- Redundant Systems: Implementation of dual or multiple redundant pathways to maintain functionality despite potential failures.

- Fault Detection and Correction: Advanced diagnostic systems capable of real-time fault detection and immediate correction to ensure continuous vehicle operation.

- Rigorous Testing Protocols: Exhaustive testing under simulated extreme conditions, including temperature variations, mechanical shocks, vibrations, and environmental stressors.

Reliability Design Practices

Ensuring reliability involves:

- Component Selection: Using automotive-grade components designed to perform reliably under challenging automotive conditions.

- Design-for-Reliability (DfR): Techniques including derating of components, mechanical design adjustments for vibration resistance, and advanced thermal management.

- Power Integrity: Maintaining stable power distribution networks to withstand variable electrical loads inherent in automotive applications.

Material Selection

Material choice is fundamental to ensuring PCB robustness and functionality within the demanding automotive environment:

- FR-4: Cost-effective and suitable for general automotive purposes.

- High-Tg FR-4: Improved thermal and mechanical properties ideal for under-the-hood conditions.

- Polyimide: Offers superior thermal resistance and flexibility, beneficial for applications requiring durability and complex form factors.

- Ceramic-Based Laminates: Ideal for high-frequency radar and high-performance computing due to superior dielectric properties and thermal performance.

The choice of materials significantly affects the PCB’s performance, impacting its ability to handle high temperatures, mechanical stress, signal integrity, and overall reliability.

Data Transmission

Autonomous vehicles require robust and high-speed data transmission capabilities to handle massive volumes of sensor data effectively. Key considerations in PCB design include:

- Signal Integrity: Managing impedance-controlled routing and differential pair matching to ensure minimal signal degradation.

- Robust Connectivity: Ensuring reliability of connectors and cable assemblies to withstand continuous vibrations and temperature fluctuations.

- Advanced Protocols: Employing high-speed communication protocols such as Gigabit Ethernet, PCIe, and SerDes to facilitate rapid and reliable data transfer within the vehicle.

EMI/EMC Considerations

Managing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) is crucial for autonomous vehicles. Effective PCB design strategies include:

- Grounding Techniques: Utilizing star grounding and well-defined separation of analog, digital, and power domains to minimize interference.

- Shielding: Implementation of metal enclosures, shielded cables, and ferrite beads to mitigate interference effects.

- Filtering and Decoupling: Use of filters, capacitors, and common-mode chokes to reduce electrical noise and enhance signal integrity.

- Compliance Testing: Rigorous EMI/EMC testing according to automotive industry standards (e.g., CISPR 25) to ensure regulatory compliance.

Case Studies

Case Study 1: Tesla Model 3

Tesla’s Model 3 incorporates advanced PCB design techniques that ensure high reliability and efficient thermal management. Tesla employs sophisticated automotive-grade materials and integrated cooling systems, significantly enhancing reliability and operational performance under various environmental conditions.

Case Study 2: Waymo’s Autonomous Vehicles

Waymo’s autonomous driving platform emphasizes redundancy, high-speed data integrity, and robust EMI/EMC management. Their PCB designs include multi-layered high-performance substrates, fault-tolerant configurations, and extensive EMI shielding techniques to ensure reliable autonomous operation.

Case Study 3: NVIDIA DRIVE AGX Platform

The NVIDIA DRIVE AGX platform integrates high-performance GPUs and processors requiring advanced PCB designs. NVIDIA incorporates innovative thermal management solutions such as copper heat pipes and vapor chambers, combined with advanced power integrity strategies, ensuring stable high-performance operation critical for autonomous vehicles.

Additional Relevant Topics

Thermal Management

Effective thermal management solutions—including thermal vias, heat sinks, liquid cooling, and specialized thermal interface materials—are essential for maintaining optimal performance and reliability of PCBs within autonomous vehicles.

Compliance with Automotive Standards

Ensuring adherence to automotive standards such as AEC-Q100, AEC-Q200, and IPC guidelines is essential to meet stringent reliability and quality requirements specific to automotive applications.

Future Trends in PCB Design

Emerging advancements in PCB technologies—including high-density interconnects (HDI), embedded passive components, and flexible PCBs—promise significant enhancements in autonomous vehicle capabilities, supporting increased complexity and improved performance.

Conclusion

Robust PCB design is essential to the safe, reliable, and efficient operation of autonomous vehicles. Through comprehensive safety protocols, optimal material selection, robust data transmission practices, and stringent EMI/EMC compliance, engineers can design advanced PCBs capable of enduring the challenging conditions of autonomous vehicle operations. Ongoing advancements in PCB design and manufacturing technologies will continue to drive innovation and facilitate the broader adoption of autonomous transportation systems.