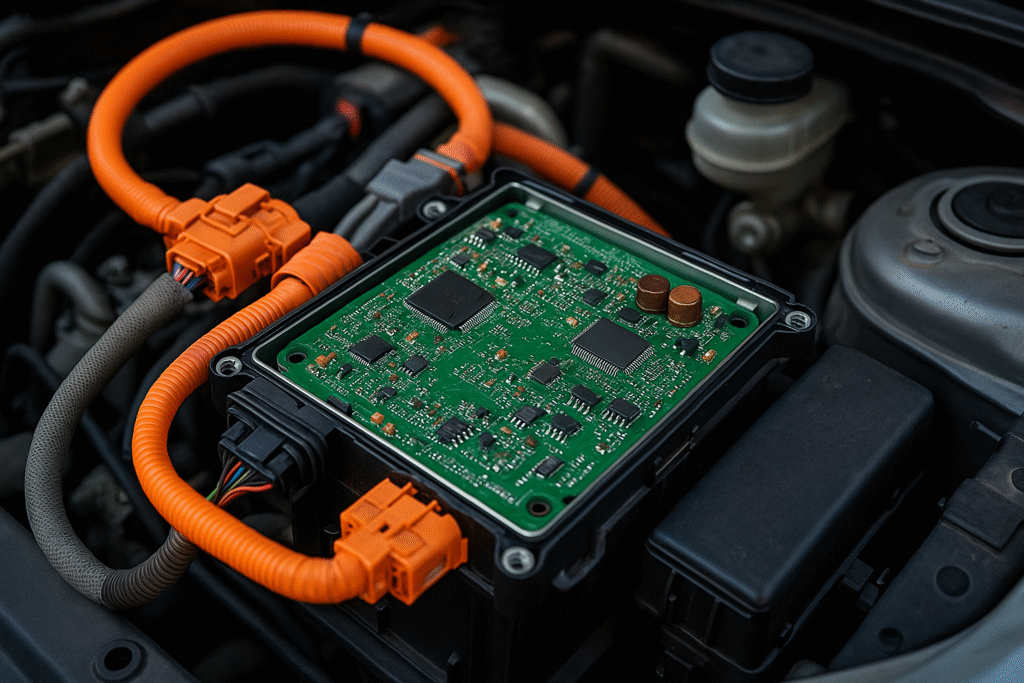

Automotive electronics have transformed modern vehicles from mechanical machines into intelligent, high-performance computing platforms. From engine control units to driver assistance systems, electronics dictate the precision, safety, and comfort of today’s cars. At the core of these systems is effective pcb design, a fundamental aspect of building robust and reliable automotive-grade circuits. As vehicles continue integrating more digital systems, the role of automotive electronics becomes increasingly pivotal across all tiers of automotive manufacturing.

Automotive Electronics Design

Designing electronics for automotive applications is vastly different from general consumer electronics due to stringent reliability, temperature, and safety requirements. Engineers must prioritize electromagnetic compatibility, thermal management, and long product lifespans.

Most automotive electronic systems are structured around microcontrollers or system-on-chip (SoC) units, working in coordination with sensors and actuators. These are responsible for mission-critical functions like powertrain control, braking, steering, and even advanced infotainment systems.

PCB layout is central to this process. Multi-layer PCBs are often used to support high-density routing and isolation between power and signal layers. Materials such as FR-4, polyimide, and metal-core boards are selected based on the required thermal and mechanical performance. Component placement must allow for effective heat dissipation and minimal signal interference, especially in high-speed communication lines like CAN, LIN, and FlexRay.

Design Considerations for Automotive Electronics

- Environmental Durability: Automotive electronics must withstand high vibrations, moisture, dust, and extreme temperatures. Conformal coatings, vibration-resistant soldering techniques, and ruggedized housings are essential.

- Power Management: Power distribution in cars is complex due to voltage fluctuations from start-stop systems and regenerative braking. Protection circuits, transient voltage suppression, and redundant power supply lines are key considerations.

- Functional Safety (ISO 26262): All automotive electronic designs must adhere to functional safety standards. This includes implementing diagnostic features, safe-state transitions, and fail-operational capabilities for systems like electronic braking and airbags.

- Software Integration: Electronics are deeply tied to embedded software. Real-time operating systems (RTOS) and automotive-grade software stacks such as AUTOSAR ensure timing precision, interoperability, and upgradability.

- Signal Integrity and EMI Mitigation: High-frequency lines need impedance control and proper grounding to avoid signal loss or corruption. Shielding and filtering techniques are used to mitigate EMI.

- Manufacturability and Testing: Design for manufacturability (DFM) and design for testability (DFT) principles are applied. This includes placing test points, selecting inspection-friendly components, and validating designs through thermal cycling, HALT, and HASS testing.

Electronics in Autonomous Vehicles

Autonomous vehicles elevate the need for advanced automotive electronics. These vehicles rely on a network of sensors such as LiDAR, radar, ultrasonic sensors, GPS, and high-resolution cameras. Each sensor generates massive amounts of data, processed in real time by central control units and edge AI processors.

Redundancy and latency become mission-critical in this context. Autonomous vehicles are built on fail-operational architectures, where secondary systems immediately take over in case of a fault. In addition, low-latency communication between components is vital. Technologies such as Ethernet AVB (Audio Video Bridging) and TSN (Time Sensitive Networking) are being adopted for in-vehicle networking.

Battery management systems, predictive diagnostics, and AI acceleration modules are embedded into the vehicle to enhance performance and user safety. Automotive electronics in autonomous platforms are pushing the boundaries of silicon integration, power optimization, and cybersecurity.

Safety Standards in Automotive Electronics

Safety in automotive electronics is mandated through rigorous international standards. The most prominent is ISO 26262, which defines functional safety requirements throughout the product lifecycle.

Other relevant standards include:

- AEC-Q100/Q200: Qualification standards for integrated circuits and passive components.

- ASIL (Automotive Safety Integrity Levels): A risk classification scheme used in ISO 26262 to determine the required integrity level.

- ISO/SAE 21434: Cybersecurity standard for automotive electronic systems.

- IEC 61508: Functional safety standard for electrical/electronic systems, applied in high-voltage automotive applications.

These standards dictate test procedures, design documentation, failure mode analysis (FMEA), and hardware/software co-validation protocols. Safety compliance is not a one-time effort but an ongoing validation that continues post-deployment through OTA (over-the-air) updates and diagnostics.

Future Trends in Automotive Electronics

The future of automotive electronics is shaped by several interrelated trends that will redefine how cars are built, operated, and experienced.

- Zonal Architecture: Traditional automotive architectures are evolving from ECU-centric designs toward zonal architectures. This consolidates control units into zones (front, rear, cabin) connected via high-speed Ethernet, reducing wiring complexity and improving scalability.

- Software-Defined Vehicles (SDVs): Electronics are enabling vehicles where software updates define behavior and features. Vehicle functions like steering responsiveness or entertainment features are now modifiable via OTA updates.

- Edge AI Processing: AI is increasingly processed at the edge using specialized automotive chips. This reduces latency in driver assistance systems, road sign recognition, and in-cabin monitoring.

- Increased Electrification: Electric vehicles (EVs) require more robust power electronics, onboard chargers, DC-DC converters, and motor control systems. Advanced power semiconductor materials like SiC and GaN are being deployed.

- Cybersecurity-First Design: With vehicles connected to cloud platforms and external networks, secure communication protocols, encrypted firmware, and intrusion detection systems are standard features.

- High-Performance Infotainment: Touchless controls, haptic feedback, 3D audio, and augmented reality dashboards are setting new benchmarks in infotainment systems.

- Energy-Efficient Lighting and Displays: LED and OLED lighting, along with energy-efficient displays, are being integrated for adaptive lighting systems and user interfaces.

Conclusion

Automotive electronics are no longer secondary systems but foundational elements driving innovation, safety, and sustainability in vehicles. From the basic engine controller to the full autonomy stack, these electronic systems demand excellence in design, testing, integration, and compliance.

PCB design remains at the heart of this transformation, enabling the reliable and scalable implementation of electronics in harsh automotive environments. As the industry moves toward more intelligent and connected transportation, the role of electronic engineering will continue to expand, setting the course for the vehicles of tomorrow.