Bare-metal embedded programming is one of the most fundamental yet advanced approaches in embedded systems development. Instead of relying on operating systems or middleware, bare-metal programming places developers in direct control of the hardware, writing code that runs without abstraction layers. This approach is essential for applications requiring real-time performance, minimal overhead, and deterministic behavior. Achieving success in bare-metal environments requires not only low-level coding expertise but also strong integration with hardware, where careful pcb design ensures the microcontroller and peripherals operate reliably under strict timing constraints. In this article, we’ll explore the principles of bare-metal programming, startup routines, peripheral drivers, schedulers, and trade-offs.

What is Bare-Metal Programming?

Bare-metal programming refers to writing software that interacts directly with hardware without an operating system. Unlike applications running on Linux or RTOS-based systems, bare-metal code typically includes only:

- Initialization routines.

- Peripheral drivers.

- Application logic.

- Interrupt service routines (ISRs).

This results in maximum control over the device. For example, in automotive safety-critical systems such as ABS controllers, bare-metal programming ensures predictable execution times without OS-induced latency.

Key Characteristics

- No OS kernel: Developers manage scheduling, memory, and timing manually.

- Direct register access: Code manipulates microcontroller registers to configure hardware peripherals.

- Deterministic performance: Timing is fully under developer control.

- Minimal resource usage: Eliminates OS overhead, crucial for devices with kilobytes of memory.

Bare-metal programming is typically used in microcontrollers, simple IoT nodes, medical devices, and safety-critical systems.

Startup Code and Initialization

When a microcontroller powers on, it follows a well-defined startup sequence. Bare-metal developers must understand and often modify this sequence.

Boot Process

- Reset vector: CPU fetches the initial program counter from the vector table.

- Stack pointer initialization: Sets the stack for runtime operations.

- Copying .data section: Initializes variables stored in RAM with values from flash.

- Zeroing .bss section: Clears uninitialized variables.

- Calling main(): Execution begins with developer-defined code.

Linker Script

In bare-metal programming, the linker script defines memory layout:

- Flash memory allocation for code.

- RAM regions for variables and stacks.

- Peripheral-mapped addresses for I/O registers.

Proper configuration of the startup code ensures predictable execution and avoids undefined behavior.

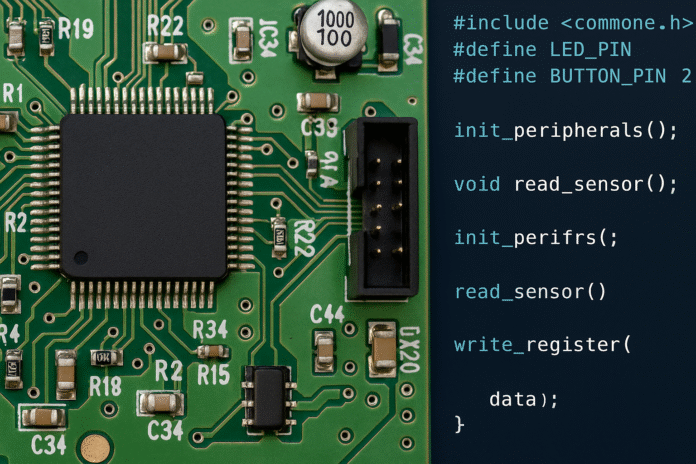

Peripheral Access and Device Drivers

Interfacing with peripherals is at the heart of bare-metal development. This involves writing low-level drivers that directly manipulate control registers.

GPIO (General-Purpose I/O)

- Configured by setting direction registers.

- Used for LEDs, buttons, and digital signals.

Timers and Counters

- Provide precise delays and pulse-width modulation (PWM).

- Essential for motor control and sensor sampling.

Communication Interfaces

- I2C and SPI: Connect sensors, memory devices, and displays.

- UART: Used for debugging and serial communication.

- CAN bus: Common in automotive networks.

ADC and DAC

- ADC converts sensor signals to digital values.

- DAC generates analog output for control systems.

Developers must write device drivers that handle register-level access, interrupts, and error states. Unlike OS-based systems, these drivers are lightweight and purpose-built.

Lightweight Schedulers vs. Full RTOS

One of the major decisions in embedded systems design is whether to remain bare-metal or adopt an RTOS.

Bare-Metal Scheduling

In a bare-metal system, scheduling can be as simple as:

- Superloops: Infinite loops running tasks sequentially.

- Interrupt-driven execution: Critical tasks handled in ISRs.

- Cooperative schedulers: Time-sliced loops for multiple tasks.

This approach works well for simple applications with limited concurrency.

RTOS Scheduling

An RTOS provides:

- Multithreading.

- Priority scheduling.

- Inter-task communication.

However, RTOS introduces additional memory and processing overhead. Bare-metal systems avoid this overhead but require careful design to prevent priority inversion, race conditions, and missed deadlines.

Advantages and Trade-Offs

Advantages

- Performance: Maximum efficiency with no OS overhead.

- Determinism: Predictable execution, ideal for real-time systems.

- Resource efficiency: Runs on devices with minimal memory.

- Control: Developers have full hardware access.

Trade-Offs

- Development complexity: Requires deep knowledge of hardware.

- Maintainability: Large bare-metal codebases are harder to scale.

- Portability: Code tied to specific microcontrollers.

- Debugging difficulty: Fewer tools and abstractions available.

Thus, bare-metal is ideal for mission-critical, resource-limited, or performance-sensitive systems but may not suit complex multi-tasking applications.

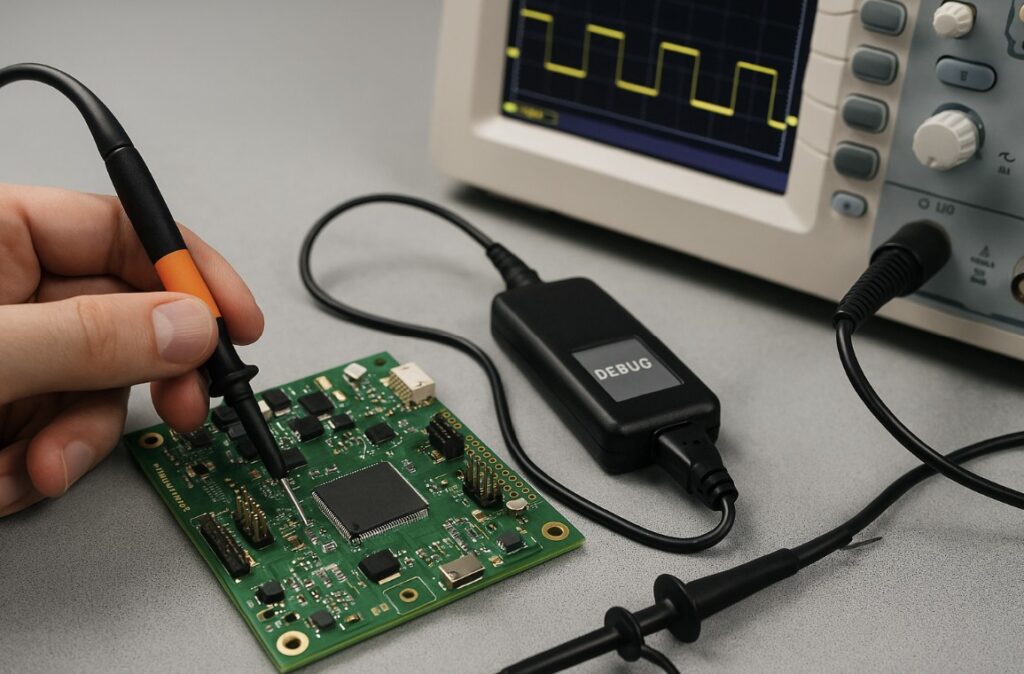

Debugging Bare-Metal Systems

Debugging without an OS can be challenging. Engineers rely on hardware and software tools such as:

- JTAG/SWD debuggers: Allow register inspection and step-through debugging.

- Serial output (UART logs): Provides runtime insights.

- Oscilloscopes and logic analyzers: Validate signal timing.

- Trace analyzers: Capture real-time execution flow.

Well-placed debug hooks and modular code design make troubleshooting manageable.

Bare-Metal vs. OS-Based Development

Choosing between bare-metal and OS-based approaches depends on application needs.

| Criteria | Bare-Metal | OS-Based |

|---|---|---|

| Performance | Maximum, no overhead | Moderate, due to scheduling and kernel |

| Complexity | High for large systems | Easier with built-in multitasking |

| Memory use | Extremely low | Higher, requires RAM and flash |

| Determinism | Very high | Limited by context switching |

| Portability | Tied to MCU | Easier with OS abstraction |

Bare-metal programming excels in time-critical, resource-constrained systems, while OS-based approaches shine in connected, feature-rich devices.

Real-World Applications

Automotive Safety Systems

- Airbag deployment controllers use bare-metal programming for deterministic execution.

- CAN communication stacks often run without OS overhead.

Medical Devices

- Pacemakers rely on ultra-low-power bare-metal systems for longevity.

- Safety requires predictable control with no OS latency.

IoT Nodes

- Bare-metal MCUs in wireless sensors prioritize low energy and compact firmware.

- Devices transmit data intermittently while staying in sleep mode.

Consumer Electronics

- TV remotes, calculators, and appliances often run bare-metal code.

These applications highlight the enduring relevance of bare-metal development.

Role of PCB Design in Bare-Metal Programming

Bare-metal code performance is strongly influenced by pcb design:

- Signal routing: Clean paths ensure stable clock and data signals.

- Power distribution: Adequate decoupling capacitors prevent voltage dips that disrupt software execution.

- Debug headers: JTAG/SWD access requires proper pin breakout.

- Thermal considerations: Protect microcontrollers from overheating.

A poorly designed PCB can negate the benefits of optimized bare-metal code, underscoring the synergy between hardware and software.

Future of Bare-Metal Programming

While high-level frameworks and RTOSs are expanding, bare-metal programming remains vital. Future trends include:

- Ultra-low-power MCUs: Energy-harvesting IoT nodes demand bare-metal efficiency.

- Safety-critical industries: Automotive and medical devices will continue to rely on bare-metal for determinism.

- AI at the edge: Lightweight bare-metal implementations may support inference tasks.

- Co-simulation with pcb design tools: Integrated workflows will allow hardware-software co-design.

Bare-metal programming will remain essential in embedded engineering, particularly as energy efficiency and reliability demands grow.

Conclusion

Bare-Metal Embedded Programming gives developers unmatched control over microcontrollers, making it ideal for systems demanding high efficiency, predictability, and minimal resource usage. From startup code to peripheral drivers and lightweight schedulers, bare-metal programming provides a foundation for mission-critical applications in automotive, medical, industrial, and consumer electronics. While it comes with trade-offs such as increased complexity and reduced portability, its advantages in determinism and efficiency make it indispensable. Together with robust pcb design, bare-metal programming remains a cornerstone of embedded engineering.