In today’s world of pcb design and electronics manufacturing, efficient and reliable interconnections are the foundation of system performance. Every electronic product—from industrial controllers to medical devices—depends on a network of cables and wires to transmit signals and power between components. This critical infrastructure is made possible through cable and wire harness assembly services, which provide organized, tested, and durable wiring systems tailored to specific applications.

Cable and wire harness assembly is far more than bundling wires together; it involves engineering design, material selection, precision assembly, and rigorous testing. The result is a product that ensures electrical integrity, simplifies installation, and enhances safety and serviceability. Whether used in aerospace, automotive, telecommunications, or consumer electronics, a properly designed harness directly impacts reliability and performance.

Cable Harness Assembly

A cable harness assembly is a structured grouping of cables or wires that transmit electrical power and signals in a controlled and organized manner. The main goal of a harness is to simplify wiring systems, reduce installation time, and minimize the risk of loose connections or damage.

Each harness typically includes wires, connectors, terminals, protective sleeving, and insulation materials, all tailored to the device’s electrical and mechanical requirements. Cable harnesses are often custom-designed for a specific application, taking into account voltage ratings, current loads, environmental factors, and spatial constraints.

The advantages of using cable harness assemblies include:

- Reduced installation errors and assembly time

- Improved protection against vibration, abrasion, and moisture

- Simplified troubleshooting and maintenance

- Enhanced aesthetics and cable organization

Cable harness assemblies are used across industries such as automotive, industrial automation, aerospace, telecommunications, and consumer electronics—where precision and reliability are non-negotiable.

Wire Harness Manufacturing

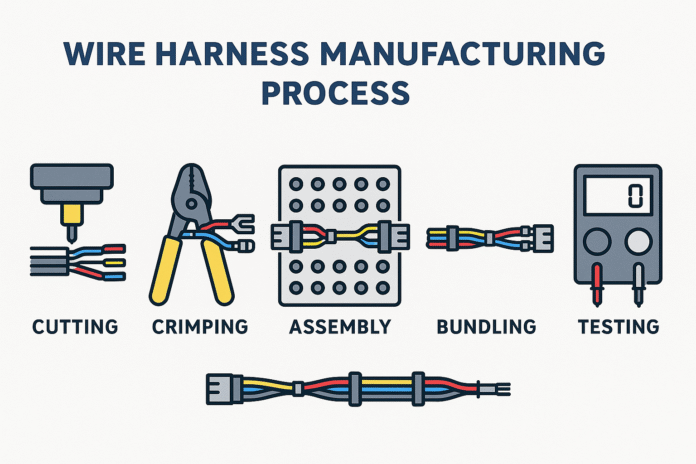

Wire harness manufacturing is a step-by-step process that transforms raw wire and connector components into finished wiring systems ready for installation. It requires both skilled labor and advanced automation equipment to meet high-quality standards.

Typical stages of wire harness manufacturing include:

- Design and Engineering: Engineers create detailed harness diagrams or schematics that define wire lengths, connector types, pin configurations, and routing paths.

- Cutting and Stripping: Automated machines cut wires to precise lengths and remove insulation at the ends.

- Crimping and Termination: Terminals or pins are crimped onto wire ends using specialized tooling to achieve reliable electrical and mechanical connections.

- Assembly Board Setup: The wires are laid out on a harness board or jig to maintain accurate routing and orientation.

- Bundling and Wrapping: Wires are grouped using cable ties, braided sleeves, or heat-shrink tubing for protection and organization.

- Testing and Inspection: Electrical continuity, insulation resistance, and high-voltage tests confirm performance and reliability.

This structured approach ensures each harness meets the required specifications and can withstand the environmental stresses of its intended application.

Custom Cable Assemblies

Modern electronics often require custom cable assemblies that go beyond standard configurations. Custom assemblies are engineered to fit specific design constraints, operating conditions, and performance targets.

Examples include:

- High-frequency coaxial cables for RF and data communication.

- Power distribution cables for high-current applications.

- Flat ribbon cables for compact PCB interconnections.

- Hybrid assemblies combining signal, power, and fiber-optic lines in one harness.

Designing a custom cable assembly involves selecting conductor materials, insulation types, shielding methods, and connector interfaces that align with the end-use requirements. For instance, cables used in outdoor telecom installations may need UV-resistant jackets and moisture seals, while medical assemblies demand biocompatible materials and sterilization compatibility.

Military Cable Assembly

Military cable assemblies represent some of the most rugged and demanding harness designs in the industry. They must operate reliably in extreme environments—exposure to heat, cold, shock, vibration, and electromagnetic interference (EMI).

Key characteristics of military-grade assemblies include:

- MIL-Spec Compliance: Designed to meet standards such as MIL-DTL-38999, MIL-DTL-5015, and MIL-C-26482.

- EMI/RFI Shielding: Braided shields and conductive jackets prevent signal degradation from electromagnetic interference.

- Environmental Sealing: Waterproof and dust-tight connectors protect against contaminants.

- Durable Construction: Reinforced insulation and abrasion-resistant jacketing for extended service life.

Military and defense applications include communication systems, avionics, radar units, navigation equipment, and ground vehicles. These cable systems must pass extensive qualification tests before being deployed.

Medical Wire Harness

In the healthcare industry, medical wire harnesses are vital for connecting sensors, diagnostic equipment, and life-support systems. Precision, safety, and cleanliness are the top priorities in this field.

Medical harnesses are designed under strict regulatory frameworks such as ISO 13485 and FDA guidelines. Common applications include:

- Patient monitoring systems

- Imaging equipment (MRI, CT, X-ray)

- Surgical tools and robotic systems

- Diagnostic devices and laboratory analyzers

Medical cable assemblies require specialized materials that resist chemicals, sterilization processes, and repeated flexing. Silicone, TPE, and medical-grade PVC are often used for insulation and jacketing. These assemblies also undergo rigorous electrical and biocompatibility testing to guarantee patient safety and performance stability.

Audio/Video Wiring Harness

Audio/video wiring harnesses are used in broadcasting, entertainment systems, automotive infotainment, and professional sound equipment. These harnesses carry both analog and digital signals and must maintain high fidelity while minimizing noise and interference.

Key design considerations include:

- Shielded Cables: Prevent electromagnetic interference for clean signal transmission.

- Gold-Plated Connectors: Enhance conductivity and reduce corrosion over time.

- Balanced Wiring: Minimizes signal loss across long cable runs.

- Custom Lengths and Terminations: Fit specific installations or enclosures.

High-quality A/V harnesses are critical in environments such as recording studios, theaters, and vehicle entertainment systems, where signal clarity defines performance quality.

Cable Assembly Company

Choosing a reliable cable assembly company is essential for achieving consistent quality, fast turnaround, and long-term reliability. A professional manufacturer provides end-to-end services, from design consultation and prototyping to volume production and testing.

A good cable assembly company typically offers:

- Design Assistance: Helping customers optimize cable routing, connector selection, and shielding.

- Prototyping Services: Building small batches for evaluation before mass production.

- Automated Manufacturing: Using precision machinery for cutting, stripping, and crimping.

- Testing and Certification: Performing continuity, high-pot, and environmental tests.

- After-Sales Support: Offering repair, modification, and technical documentation.

Partnering with an experienced manufacturer reduces risks of production delays, component incompatibility, or electrical faults. Companies like Arshon Technology, for instance, integrate cable assembly expertise with pcb design and system engineering, providing complete electronic solutions.

UL/CSA Cable Assembly

UL and CSA certifications are key indicators of product safety and compliance. UL/CSA cable assemblies are tested against stringent electrical and mechanical standards to guarantee reliability in industrial and consumer applications.

- UL (Underwriters Laboratories) focuses on U.S. standards for electrical safety and performance.

- CSA (Canadian Standards Association) certifies products for the Canadian market.

Certified assemblies undergo testing for insulation resistance, flame retardancy, dielectric strength, and temperature endurance. Using UL/CSA-approved assemblies not only meets legal requirements but also builds customer confidence and reduces liability for manufacturers.

Wire Harness Process

The wire harness process involves several coordinated steps to achieve consistency, accuracy, and quality. Each harness follows a documented manufacturing plan to maintain traceability and repeatability.

The process typically includes:

- Design and Documentation: CAD drawings define wire lengths, routing paths, and terminal configurations.

- Wire Preparation: Automated systems cut, strip, and mark wires according to the schematic.

- Crimping and Soldering: High-precision machines attach terminals, ensuring solid electrical contact.

- Laying Out on Assembly Board: Technicians position wires on a formboard that replicates the final layout.

- Bundling and Protection: Heat-shrink tubing, spiral wrap, or braided sleeves are applied.

- Testing and Quality Control: Electrical and visual inspections confirm continuity, resistance, and compliance with design standards.

Quality assurance is integrated throughout the process, with documentation for every stage to meet ISO 9001 and IPC/WHMA-A-620 standards.

Harness Fabrication Services

Harness fabrication services provide turnkey solutions for companies that require ready-to-install wiring systems. These services range from prototyping and low-volume builds to large-scale production runs.

Leading fabrication services include:

- Rapid Prototyping: Short-run samples for design verification.

- Mass Production: Automated assembly lines for consistent output.

- Overmolding and Encapsulation: Enhancing mechanical durability and environmental protection.

- Testing and Validation: Electrical testing, pull-force testing, and mechanical durability assessments.

- Documentation and Traceability: Complete production records for regulatory compliance.

Outsourcing harness fabrication allows OEMs to focus on product development while leveraging specialized manufacturing expertise to reduce cost and time-to-market.

Applications of Cable and Wire Harness Assemblies

Cable and wire harness assemblies are indispensable across industries, including:

- Automotive: Engine control units, lighting, infotainment, and safety systems.

- Aerospace: Avionics, navigation, and satellite communication systems.

- Industrial Automation: Robotics, sensors, and power distribution systems.

- Telecommunications: Network routers, base stations, and data centers.

- Renewable Energy: Solar panels, battery systems, and wind turbine controllers.

Each industry demands specific materials, tolerances, and standards, making customization and certification essential to meet performance expectations.

Conclusion

Cable and wire harness assembly services are the foundation of modern electronic connectivity. They combine engineering precision, quality materials, and manufacturing expertise to create reliable interconnections that power today’s technology. From pcb design and prototyping to large-scale production, harness assemblies simplify wiring systems, reduce errors, and enhance product reliability.

Whether for medical devices, aerospace equipment, or industrial automation, choosing the right assembly partner ensures consistency, compliance, and durability. As electronic systems continue to evolve, cable and wire harness technologies will remain a key enabler of innovation, supporting smarter, safer, and more connected products.