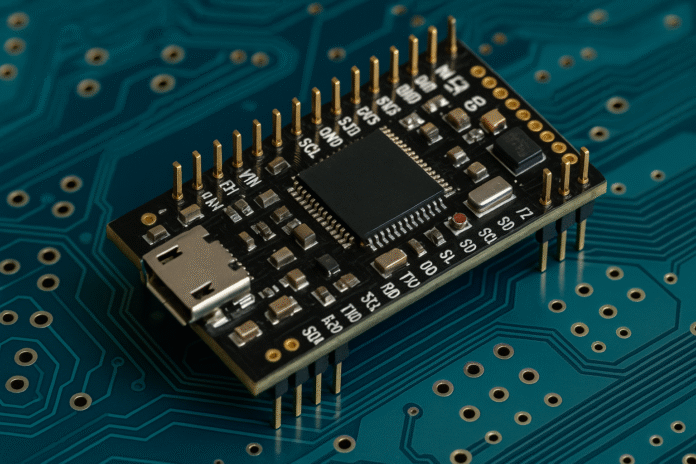

Choosing the right microcontroller is one of the most influential decisions in embedded product development. From system architecture and power budget to manufacturability and firmware delivery, the MCU you select affects the entire product lifecycle. Early technical decisions should include considerations for PCB layout and pcb design, power distribution, and test access so the chosen device can be integrated without late rework. This article walks through a practical, engineering-focused process to Choose the Right Microcontroller for Your Embedded System, covering requirements capture, common architectures, peripheral tradeoffs, performance sizing, power budgeting, development ecosystem, production concerns, and final checklist items to reduce risk and accelerate time to market.

What is a microcontroller in an embedded system?

A microcontroller is a single integrated circuit that contains a CPU core, memory, and peripherals tailored for control tasks. It typically includes on-chip flash for code, SRAM for runtime data, timers, ADCs, DACs, serial interfaces (UART, SPI, I²C), and GPIO. Compared with application processors, microcontrollers are optimized for deterministic timing, low power draw, quick boot times, and cost-effective BOM. In an embedded system the MCU runs firmware that interacts with sensors, actuators, communications modules, and user interfaces to deliver a controlled function.

How to choose the correct microcontroller?

Start by translating product needs into measurable constraints. A clear requirements matrix prevents feature creep and lets you filter candidates quickly. Key fields to capture are: worst-case control loop rates and ISR latencies, total code and data memory required with headroom for OTA and logging, required analog performance (ADC resolution, sample rate), communications and interfaces (number and type), power constraints (battery capacity and duty cycle), environmental range, security needs, and target unit cost. With this data you can apply a staged filter: eliminate devices lacking required peripherals or memory, then focus on core performance, power characteristics, and ecosystem maturity. Always include a longer-term availability check and at least one compatible alternate.

Which microcontroller architecture is commonly used in embedded systems?

ARM Cortex-M architecture dominates modern embedded development because of broad vendor support and a mature toolchain. Cortex-M0+/M3 suit low-power control, M4 and M7 give DSP and FPU for sensor fusion and audio, M33 adds on-chip security features, and M55 introduces vector extensions for ML inference. RISC-V is gaining momentum offering open ISA flexibility and competitive power/performance. Established 8-bit families such as AVR and PIC remain valid where ultra-low cost and minimal code size are primary drivers. For designs that need an operating system and heavy networking or GUIs, an application processor (ARM Cortex-A class) paired with a small MCU for real-time tasks is a common pattern.

What are the three main components of a microcontroller?

The three essential elements are: the CPU core (execution engine), memory (nonvolatile flash for program storage and volatile SRAM for stacks and buffers), and peripherals/I-O (timers, ADCs, DACs, serial interfaces, DMA engines). Modern MCUs may also add crypto accelerators, TRNGs, hardware event routers, and power domains to support low-power operation.

Is a Raspberry Pi a microcontroller?

No. Typical Raspberry Pi boards are single-board computers built around application processors that run Linux and contain a memory management unit (MMU). They provide rich OS features at the cost of longer boot times, higher power use, and less deterministic timing. The Raspberry Pi Pico (RP2040) is an exception: it is a microcontroller board and fits the embedded MCU pattern.

Is ESP32 a microcontroller?

Yes. The ESP32 family integrates microcontroller cores and wireless radios on a single package. Many products choose ESP32 for cost-effective Wi-Fi/BLE connectivity when the radio and MCU on one chip removes the need for an external modem or module. RF layout and certification still require careful attention, but the integration can reduce BOM and development time.

How to choose microcontroller frequency?

Clock speed is a tradeoff among performance, energy, and EMI. Rather than choosing an MCU for specified MHz alone, quantify the total cycle budget the application needs: cycles for ISRs, background tasks, signal processing, comms, and housekeeping. If your algorithm requires floating-point math or tight DSP loops, favor a core with FPU or DSP extensions so you get more done per cycle. Also evaluate power at typical operating points: many MCUs are more energy efficient when run briefly at higher speed and returned to deep sleep than when run slowly for longer time. Consider external timing constraints too; USB, audio, or certain codecs need clocks at specific rates.

Design process and checklist—step by step

- Requirements capture. Create a spreadsheet with functional and nonfunctional items. Include memory estimates for all firmware components, peripheral counts, ADC sampling needs, OTA space, and retention requirements.

- Prototyping targets. Choose a small set of evaluation boards from candidate vendors. Bring-up early on eval hardware will reveal unexpected issues and clarify toolchain friction.

- Sizing compute and memory. Convert your workload into cycles and bytes. For RTOS designs, budget stack per task and add secure storage for credentials. Add 30–50% headroom for future features.

- Peripheral mapping. Check pin mux options and ensure required peripherals can be mapped without conflicting with boot pins or JTAG. Pay attention to high-speed interfaces that require specific pins or board routing.

- Power model and modes. Define average and peak currents. Choose parts with ultra-low sleep modes, fast wake-up where needed, and suitable voltage range for your power supply. Include regulator efficiency in the budget.

- Security and lifecycle. Select MCUs with secure boot, signed firmware verification, hardware crypto, and lifecycle support for field updates. Plan a secure OTA with rollback protection.

- PCB and mechanical constraints. Confirm package options are manufacturable (QFN vs BGA) and that thermal dissipation and copper pours are planned. Early attention to pcb design prevents rework later.

- Ecosystem check. Examine toolchains, vendor SDKs, community support, certified stacks, and reference designs. Time saved by a well-supported SDK often outweighs a small difference in per-unit cost.

- Longevity and supply chain. Require vendor life-cycle commitments, check second-source options, and verify distribution channels to avoid mid-production shortages.

- Production readiness. Plan for programming and test fixtures, programming time per unit, and burn-in strategies.

Peripheral tradeoffs that steer selection

ADC quality: detail signal chain metrics—SNR, ENOB, sample rate, input network, and multiplexer behavior. If analog performance is a major product differentiator, choose devices with dedicated ADCs and PGA in silicon or plan for external ADCs.

Timers and PWM: for motor control or power conversion, look for high-resolution PWM, capture/compare features, dead-time insertion, and multiple timers for multi-phase control.

Communication interfaces: confirm full-duplex requirements, DMA support, and buffer sizes. For example, USB host or device operation may impose specific clock requirements and memory usage. For CAN-FD or Ethernet, ensure MAC and PHY integration expectations and certified stacks are available.

Crypto and secure elements: hardware AES, SHA, elliptic curve accelerators, and TRNGs accelerate operations and protect keys without burdening the CPU. Consider secure elements for key storage in high-security applications.

Real-world constraints and mitigations

Cost vs schedule: an MCU that cuts firmware effort or includes an on-chip radio can shorten schedule and reduce BOM even if its per-unit cost is higher. Plan for total cost of ownership, including development time, test time, and field support.

Availability: pick a family with multiple package options and pin-compatible variants for scaling up performance or reducing cost without redesigning PCB.

Regulatory scope: if you need FCC, CE, automotive, or medical approvals, prefer vendors and modules that already have tested stacks or pre-certified RF modules to reduce certification risk.

Thermal concerns: running at sustained high MHz increases board temperature. Plan thermal vias, copper pours, and component placement to avoid hotspots. For high power, include thermal measurements in prototype testing.

Power and energy strategies

Low energy design often wins product features. Several patterns work well: run-to-completion then deep sleep, event-driven wakeups with hardware interrupts, offload sensor pre-processing to low-power peripherals or sensor hubs, and use DMA for bulk transfers to avoid waking the CPU. Evaluate regulator choices: switching regulators for efficiency across a wide input range and LDOs for quiet analog rails. Measure real current on prototype boards under representative duty cycles to validate spreadsheet estimates.

Software architecture and toolchain considerations

Choose an RTOS when concurrency, networking, or modular drivers are needed. FreeRTOS and Zephyr are common choices, with Zephyr providing more built-in device support in some ecosystems. Verify debug support (SWD, SWO, tracing) and continuous integration toolchain workflows. Unit tests, hardware-in-the-loop tests, and static analysis reduce shipping defects. Use bootloader and firmware layout with dual banks and a verified recovery path for safe OTA operations.

Production, test, and programming

Plan for programming in production: how long will programming take per unit, what are the secure personalization steps, and is a production key provisioning flow required? Include bed-of-nails or boundary-scan plans, and script tests that verify key peripherals. Add test points for power rails, clocks, and communications. For surface-mount packages expect X-ray or AOI inspection to validate solder quality at scale.

When to use modules vs discrete MCU packages

Modules containing MCU + radio + certified antenna simplify RF certification and speed time to market at higher per-unit cost. Use modules when RF certification or antenna layout is out of scope for the team or project timeline. Choose discrete parts when cost, board footprint, or size constraints make an integrated approach necessary and the team can handle RF layout and certification.

Is a two-chip architecture needed?

Use a companion device when conflicting requirements exist: a tiny MCU for very low sleep current paired with a higher-performance MCU or application processor for computationally heavy tasks; an MCU dedicated to safety-critical control and another for connectivity; or when regulatory boundaries separate functions. Keep interfaces simple and fault tolerant.

Choosing package and pinout with pcb design in mind

Pin mapping is an often overlooked source of late redesign. Lock pinout early and route critical nets first. Avoid using boot or test mode pins for signals that will be required in production. Keep SWD/JTAG accessible for bring-up and include test pads for production programming. Select a package that matches assembly capabilities: QFN and LQFP are forgiving; small BGA saves space but raises assembly cost and X-ray inspection needs. Leave test pads for power rails and high-value signals.

Security, provisioning, and product lifecycle

Security must be architected from the start. Plan for a secure root of trust, signed firmware, device-unique credentials, and secure storage. Define provisioning flows for manufacturing and field updates. Consider lifecycle states—debug enabled, provisioning, field, decommissioned—and ensure debug interfaces can be disabled in production.

What is the role of machine learning in modern design?

ML influences MCU choices when on-device inference or sensor fusion is required. TinyML models run on Cortex-M4/M7 or MCUs with vector extensions; if ML is core to the product, pick MCUs with DSP or NPU support and enough RAM to hold model tensors or plan external memory. ML can also accelerate test and yield improvements during manufacturing.

Practical examples and family snapshots (non-exhaustive)

• Low-power sensing: choose an M0+/8-bit variant with lowest sleep current and rich ADC resources.

• Motor control and sensor fusion: M4/M7 with FPU/DSP and high-resolution timers.

• Secure connected product: M33/M55 with TrustZone, hardware crypto, and Ethernet/Wi-Fi modules.

• Rapid prototyping and connected hobby projects: ESP32 or popular ARM dev boards give fast results.

Vendor ecosystems matter. ST’s STM32 line, NXP’s Kinetis and i.MX RT, Microchip’s SAM family and PIC, Nordic for BLE, and Espressif for Wi-Fi/BLE are widely used and supported.

Final checklist before committing to a part

• Does the MCU meet raw compute and memory needs with headroom?

• Are required peripherals present and pin-mappable?

• Are sleep modes and regulator choices compatible with your power budget?

• Is the vendor ecosystem mature enough to meet your schedule?

• Is there a secure boot and update story that fits product policy?

• Do package and assembly choices match manufacturing capability?

• Are supply and lifecycle risks acceptable with alternates identified?

• Have you validated clocks, PHYs, and ADC paths on eval boards?

• Have you planned production programming, test, and field update flows?

Conclusion

Choosing the right microcontroller for an embedded product is a multi-dimensional decision that mixes technical requirements, supply considerations, development productivity, and long-term maintenance. Treat the MCU selection as a systems decision: include PCB layout, power delivery, thermal management, and production test in initial evaluations. Prototype early, quantify needs in cycles and bytes, and prioritize parts with strong ecosystems and security features to reduce risk. With a disciplined process you can Choose the Right Microcontroller for Your Embedded System and move from prototype to product with confidence.