Designing and understanding brushless DC (BLDC) motor controller circuits is essential for engineers, hobbyists, and product developers. These controllers are at the heart of modern automation, robotics, electric vehicles, drones, and countless industrial systems. A BLDC motor cannot function without a proper control circuit that drives its stator windings based on rotor position. From pcb design considerations to commutation techniques and switching devices, this guide covers every aspect of BLDC motor controller circuits with detailed explanations and practical examples.

Introduction to BLDC Motor Controllers and Why They Matter

BLDC motors have replaced brushed DC motors in many applications due to higher efficiency, longer lifespan, and reduced maintenance. However, unlike brushed motors that mechanically switch current through brushes and commutators, BLDC motors rely on electronic controllers. The controller acts as the “brain” of the motor, providing the correct voltage and current to stator windings depending on the rotor’s position. This enables precise speed control, torque optimization, and smoother operation. Without the controller, a BLDC motor is just a passive set of coils and a permanent magnet rotor.

Half-Bridge vs. Full H-Bridge Circuits Explained

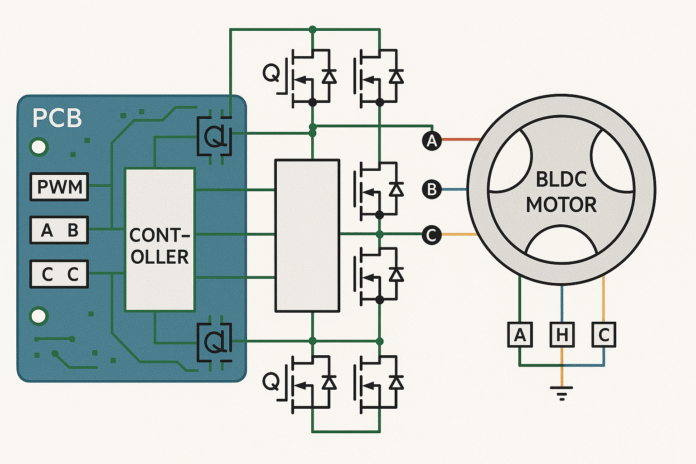

At the core of BLDC control circuits are half-bridge and full H-bridge configurations. A half-bridge uses two switches, typically MOSFETs or IGBTs, to control current in one motor phase. It allows bidirectional current flow and enables PWM modulation. A full H-bridge, made from two half-bridges, controls current in two directions across a winding. In three-phase BLDC motors, three half-bridges (six switches) are used to energize the stator windings. Engineers must consider switching losses, gate driving circuits, and thermal effects when designing H-bridges.

Three-Phase Circuit Design: How Stator Windings Are Driven

Most BLDC motors are three-phase, with stator windings arranged in either star (wye) or delta configuration. The controller energizes these windings in sequence to create a rotating magnetic field. This is typically done using a six-step commutation process:

- Apply voltage across one phase pair while leaving the third phase floating.

- Rotate the energizing sequence every 60 electrical degrees.

- Ensure torque is continuous by aligning stator fields with rotor position.

Designers use gate drivers to control MOSFETs or IGBTs, ensuring that switches operate efficiently without cross-conduction.

Using Hall Sensors for Rotor Position Detection

Accurate rotor position feedback is crucial for commutation. BLDC motors often use Hall effect sensors embedded in the stator. These sensors detect the rotor’s magnetic poles and output digital signals to the controller. Based on these signals, the controller determines which phases to energize. Alternatives include:

- Sensorless control, where back-EMF detection replaces physical sensors.

- Encoders, used in high-precision robotics.

Hall sensors are cost-effective and widely used, but sensorless methods reduce wiring and improve reliability in certain environments.

Switching Devices: MOSFET vs. IGBT in BLDC Circuits

The choice of switching devices directly impacts efficiency and cost.

- MOSFETs are preferred in low-to-medium voltage applications (below 200V) due to fast switching speeds and low conduction losses.

- IGBTs are used in higher voltage systems such as industrial drives and electric vehicles, where they handle large currents with good efficiency at lower switching frequencies.

Designers must also account for gate drivers, switching losses, and thermal dissipation. Proper heatsinking, thermal vias in the PCB, and efficient layout are vital.

Trapezoidal vs. Sinusoidal Commutation: Pros and Cons

BLDC controllers use either trapezoidal or sinusoidal commutation.

- Trapezoidal commutation (six-step) is simple and cost-effective, generating block-like waveforms. It provides good efficiency but introduces torque ripple.

- Sinusoidal commutation drives windings with sine waveforms, resulting in smoother torque, quieter operation, and improved efficiency. However, it requires more complex circuitry and processing power.

Some modern controllers use field-oriented control (FOC), which optimizes torque and efficiency by directly controlling current vectors.

Pulse Width Modulation (PWM) and Signal Smoothing

PWM is the most common technique for controlling voltage applied to BLDC motors. By adjusting duty cycles, the controller regulates motor speed and torque. However, PWM introduces high-frequency noise and losses. To reduce these effects:

- LC filters smooth signals.

- Dead-time insertion prevents simultaneous conduction of high- and low-side switches.

- Current feedback loops improve stability and control accuracy.

Engineers must carefully balance PWM frequency, switching losses, and electromagnetic compatibility (EMC).

Integrated Controller ICs vs. Discrete Circuit Designs

Designers face a choice between using integrated BLDC controller ICs or building circuits from discrete components.

- Integrated ICs simplify design, offering gate drivers, current sensing, and protection features in a compact package. They are ideal for consumer devices and compact systems.

- Discrete circuits provide more flexibility, allowing engineers to optimize for higher efficiency, higher currents, or specialized functions. These are preferred in industrial and automotive applications.

The decision often depends on cost, design complexity, and application requirements.

Common Mistakes in Designing BLDC Controller Circuits

Some frequent errors in BLDC circuit design include:

- Poor grounding, leading to noise and unstable operation.

- Insufficient dead time, causing shoot-through in MOSFETs.

- Inadequate cooling, leading to thermal failures.

- Improper sizing of gate drivers, resulting in slow switching and losses.

- Overlooking EMI/EMC compliance, which is critical in consumer and automotive products.

Avoiding these mistakes requires careful PCB layout, component selection, and simulation before production.

Practical Circuit Diagram Examples and Case Studies

Example 1: Drone BLDC Controller

A compact BLDC driver for drones uses MOSFET-based three-phase bridge circuits, Hall sensors for feedback, and high-frequency PWM for speed control. The PCB design minimizes weight and maximizes thermal efficiency.

Example 2: Electric Vehicle Motor Drive

EV motor controllers use IGBT-based inverters with liquid cooling. They employ FOC algorithms for smooth torque and high efficiency. The PCB is multilayer, supporting high currents with copper pours and robust vias.

Example 3: Industrial Automation Controller

Industrial BLDC drivers often integrate communication protocols (CAN, RS-485) for networked control. They use discrete designs with redundant protection circuits.

These examples highlight how circuit diagrams vary depending on application requirements.

Conclusion

BLDC motor controllers are essential for modern motion systems, providing efficiency, control, and flexibility across industries. Whether using half-bridge or full H-bridge designs, MOSFETs or IGBTs, trapezoidal or sinusoidal commutation, engineers must carefully balance cost, efficiency, and complexity. Attention to pcb design, component selection, and rotor position detection ensures optimal performance. By avoiding common design pitfalls and leveraging modern integrated solutions, developers can create reliable controllers for drones, EVs, wearables, and industrial automation. The future of BLDC controllers lies in smarter, more efficient designs powered by advanced algorithms and robust hardware.