DC motor controllers are essential components in various applications, from industrial machinery to consumer electronics. They regulate the operation of DC motors, ensuring precise control of speed, direction, and torque. This article explores the fundamentals of DC motor controllers, their necessity, types, selection criteria, and differences from motor drivers.

What is a DC Motor Controller?

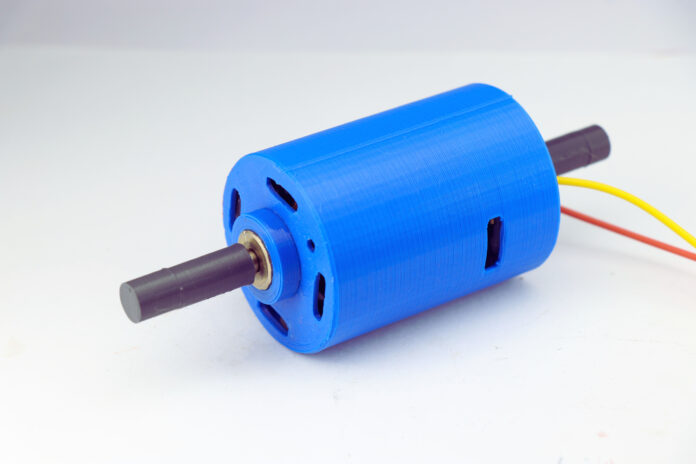

A DC motor controller is an electronic device that regulates the operation of a direct current (DC) motor. It adjusts the voltage and current supplied to the motor, controlling its speed, direction, and torque. DC motor controllers are used in various applications, including robotics, industrial automation, automotive systems, and consumer electronics.

Do DC Motors Need a Motor Controller?

Yes, DC motors typically require a motor controller to operate efficiently and reliably. While it’s possible to connect a DC motor directly to a power source, this approach offers no control over the motor’s speed or direction and can lead to inefficiencies and potential damage to the motor. A motor controller provides the necessary control and protection mechanisms to ensure optimal performance.

How Do You Control a DC Motor?

Controlling a DC motor involves several methods, each suited to different applications and requirements:

Voltage Control

By varying the voltage supplied to the motor, its speed can be adjusted. This method is simple but can be inefficient at low speeds.

Pulse-Width Modulation (PWM)

PWM control involves switching the motor’s power supply on and off rapidly. The average voltage applied to the motor determines its speed. PWM is highly efficient and provides precise control over the motor’s speed.

Direction Control

The direction of a DC motor can be reversed by changing the polarity of the voltage applied to it. This is typically achieved using an H-bridge circuit, which allows the motor to rotate in both directions.

Current Control

By regulating the current supplied to the motor, its torque can be controlled. This method is essential for applications requiring precise torque management.

What Are the Four Types of Motor Controllers?

Motor controllers can be categorized into four main types:

On/Off Controllers

These controllers provide simple on/off control of the motor. They are used in applications where precise speed or direction control is not required.

Proportional Controllers

Proportional controllers adjust the motor’s speed based on the difference between a desired setpoint and the actual motor speed. They provide smooth and continuous control.

Integral Controllers

Integral controllers focus on eliminating steady-state errors by considering the accumulation of past errors. They are often combined with proportional controllers (PI controllers) for improved performance.

Proportional-Integral-Derivative (PID) Controllers

PID controllers are advanced controllers that combine proportional, integral, and derivative control methods. They offer precise and dynamic control of the motor’s speed and position.

How Do I Choose a Motor Controller for My Motor?

Choosing the right motor controller for your DC motor involves several considerations:

Motor Specifications

Ensure that the controller is compatible with the motor’s voltage, current, and power ratings.

Control Requirements

Determine the level of control needed for your application, such as speed control, direction control, and torque control.

Environmental Conditions

Consider the operating environment, including temperature, humidity, and potential exposure to dust or moisture.

Communication Interfaces

Check if the controller supports the necessary communication interfaces for integration with other systems, such as UART, SPI, or I2C.

Budget

Balance the features and capabilities of the controller with your budget constraints.

What is the Difference Between a Motor Driver and a Motor Controller?

The terms “motor driver” and “motor controller” are often used interchangeably, but they refer to different components:

Motor Driver

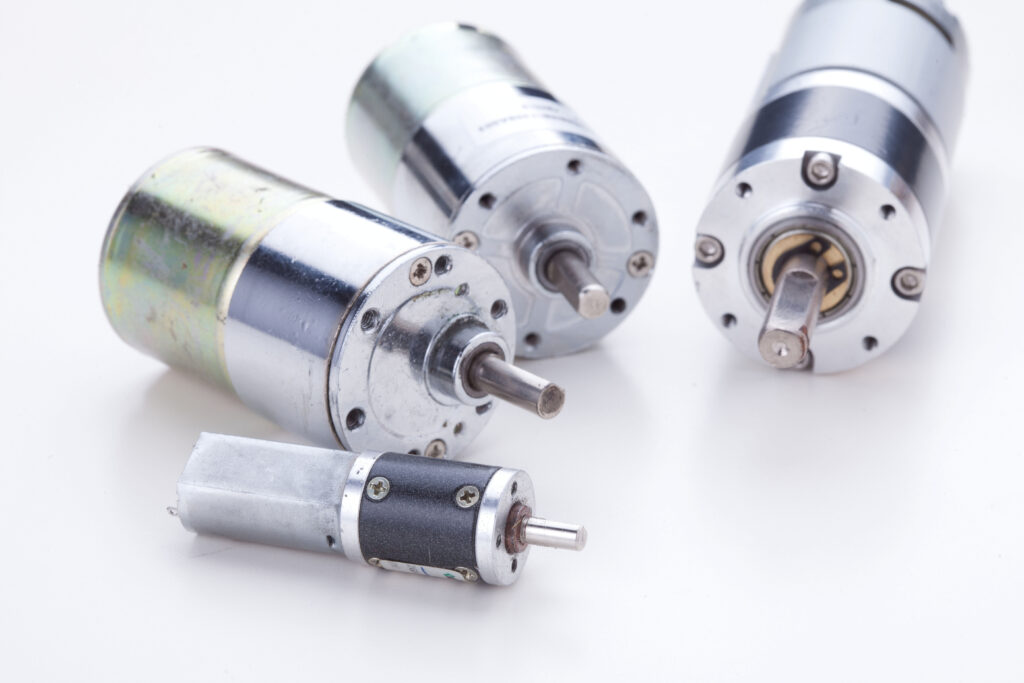

A motor driver is a simpler component that provides the necessary power amplification to drive the motor. It typically lacks advanced control features and relies on external signals to operate.

Motor Controller

A motor controller is a more sophisticated device that includes both the power amplification and control logic. It can independently manage the motor’s speed, direction, and torque, often incorporating feedback mechanisms and advanced control algorithms.

Why Use Motor Driver for DC Motor?

Using a motor driver for a DC motor offers several advantages:

Power Amplification

Motor drivers amplify low-power control signals to levels suitable for driving the motor.

Protection

Motor drivers often include protection features such as overcurrent, overvoltage, and thermal shutdown to safeguard the motor and driver.

Ease of Integration

Motor drivers simplify the integration of DC motors into various systems, providing standardized interfaces and control methods.

Do You Need a Controller for an Electric Motor?

Yes, a controller is essential for efficiently and reliably operating an electric motor. The controller provides the necessary regulation and protection to ensure optimal performance and longevity of the motor. In the case of DC motors, a controller allows precise control over speed, direction, and torque, making it indispensable for most applications.

Arshon Technology: Pioneering Innovation in DC Motor Controllers

Arshon Technology stands as a pioneer in the field of DC motor controller innovation, offering advanced solutions tailored for diverse applications. Known for their expertise in designing and manufacturing high-performance motor controllers, Arshon Technology ensures that customers receive products distinguished by their efficiency, reliability, and precision. With a commitment to continuous innovation and quality, Arshon Technology sets benchmarks in the industry, providing cutting-edge solutions that meet the evolving demands of modern motor control technology.

Conclusion

DC motor controllers are critical components for managing the operation of DC motors, providing precise control over speed, direction, and torque. Understanding the types of motor controllers, their selection criteria, and their differences from motor drivers is essential for leveraging their full potential in various applications. Companies like Arshon Technology lead the way in developing advanced motor controllers, ensuring that industries can benefit from the latest innovations in motor control technology.