Designing high-speed digital circuits for 5G applications requires precision in pcb design, signal integrity, power distribution, and thermal management. The transition from 4G LTE to 5G has brought unprecedented performance requirements—ultra-low latency, higher throughput, and millimeter-wave (mmWave) frequencies. These demands push circuit designers to adopt innovative strategies in hardware architecture, interconnect optimization, and packaging techniques. In this article, we will review the design principles, challenges, and best practices that engineers need to implement to build efficient and reliable digital circuits for 5G systems.

Introduction to 5G Circuit Design

5G technology operates across sub-6 GHz and mmWave bands, reaching frequencies as high as 52.6 GHz in commercial deployments and beyond 100 GHz in research applications. Designing circuits for such frequencies introduces challenges in propagation delay, crosstalk, impedance matching, and power integrity. Unlike traditional digital systems, 5G circuits must combine RF design with high-speed digital logic, making the PCB layout and interconnects as important as the core silicon.

Applications of high-speed digital circuits in 5G include:

- Baseband processors and digital front ends (DFE)

- Network infrastructure equipment (routers, switches, repeaters)

- Antenna modules with phased arrays

- Mobile devices and IoT terminals

- Edge computing platforms and servers

Each of these applications requires unique circuit architectures, yet they share common design concerns related to bandwidth, timing, and electromagnetic compatibility.

Signal Integrity in High-Speed Circuits

Signal integrity (SI) is the foundation of 5G circuit design. At gigabit speeds, even small discontinuities in trace width or via placement can cause reflections, jitter, and eye diagram collapse. Engineers must treat every transmission line as a controlled impedance channel.

Key factors affecting signal integrity:

- Impedance matching: Traces and connectors should be designed at 50 Ω or 100 Ω differential.

- Crosstalk control: Use proper spacing, ground shielding, and differential routing.

- Skew management: Maintain equal lengths for differential pairs to avoid phase mismatches.

- Termination techniques: Apply series or parallel termination to suppress reflections.

Simulation tools such as HyperLynx, Ansys HFSS, or Keysight ADS help verify SI before PCB fabrication.

Power Integrity in 5G Digital Systems

Power integrity (PI) is equally important because 5G chipsets operate at very low voltages with high current swings. Even minor noise in power delivery can cause timing errors or system resets.

Design recommendations:

- Deploy multi-layer decoupling with capacitors ranging from nF to µF.

- Use low-inductance vias for capacitor placement.

- Optimize the power delivery network (PDN) with target impedance calculations.

- Avoid long narrow traces for high-current rails—use planes or wide pours.

By stabilizing power delivery, designers achieve cleaner signals and higher reliability.

PCB Materials for 5G Applications

Traditional FR-4 materials cannot meet the performance needs of mmWave frequencies. Advanced substrates are essential.

Common PCB materials for 5G circuits:

- Rogers RO4350B / RO4003C: Low dielectric constant (Dk) and low dissipation factor (Df).

- Isola Astra MT77: Stable Dk across frequencies, excellent for phased arrays.

- Taconic RF laminates: Widely used for base stations.

- Hybrid stack-ups: Combine FR-4 with RF laminates to balance cost and performance.

Material selection influences insertion loss, dielectric heating, and signal propagation speed.

Thermal Management in High-Speed Circuits

5G devices generate significant heat due to high transistor density and fast switching speeds. Excessive temperatures degrade signal quality and reduce component lifespan.

Thermal solutions include:

- Thermal vias under power devices

- Copper planes for heat spreading

- Heat sinks and vapor chambers in infrastructure equipment

- Low-loss laminates that minimize dielectric heating

Simulation with tools such as COMSOL or Icepak allows engineers to predict and control thermal hotspots.

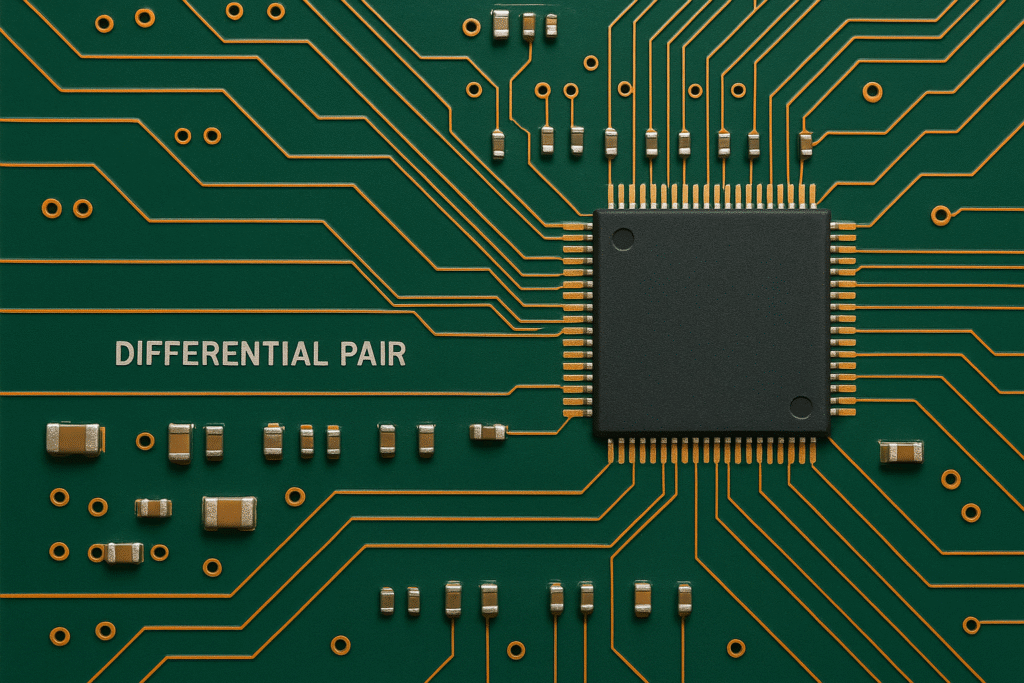

Packaging and Interconnect Challenges

High-speed interconnects require advanced packaging to minimize parasitic effects. Traditional wire bonding is unsuitable for mmWave frequencies, pushing the industry toward flip-chip, fan-out wafer-level packaging (FOWLP), and 2.5D/3D IC integration.

Design strategies:

- Short interconnects reduce inductance.

- Micro-bumps and through-silicon vias (TSVs) support 3D integration.

- Co-design of package and PCB prevents mismatches at transitions.

These packaging techniques allow 5G systems to integrate digital processors, RF front ends, and memory into a compact form factor.

High-Speed Clocking and Synchronization

Clock distribution in 5G systems is critical. Jitter, skew, and phase noise can undermine the performance of baseband processors and digital front ends.

Clock design techniques:

- Use low-phase-noise oscillators.

- Implement phase-locked loops (PLLs) with jitter cleaning.

- Shield clock traces from aggressor signals.

- Apply redundant synchronization for network nodes.

Clock networks are often verified with time-domain reflectometry (TDR) and vector network analyzers.

Electromagnetic Compatibility (EMC) and Regulatory Compliance

5G systems must meet strict EMC standards across different countries. Poorly designed circuits can radiate excessive noise or fail to reject interference.

Best practices for EMC compliance:

- Apply ground stitching vias around high-speed zones.

- Isolate analog/RF and digital grounds carefully.

- Use shielding cans for sensitive front ends.

- Maintain short return paths to reduce loop area.

Compliance testing is carried out using standards such as FCC, CE, and ETSI regulations.

Simulation and Verification Techniques

Before manufacturing, engineers must validate designs with simulation and lab testing.

Simulation domains:

- SI/PI analysis: SignalEye, PowerSI

- Electromagnetic simulation: HFSS, CST Microwave Studio

- Thermal analysis: Icepak, FloTHERM

- Timing simulation: Synopsys PrimeTime

Lab verification includes high-bandwidth oscilloscopes, vector network analyzers, and eye diagram tests.

Case Study: Designing a 5G Baseband Processing Board

Consider a digital board hosting a 5G baseband processor with DDR5 memory and PCIe Gen5 interfaces:

- PCB stack-up: 12 layers with Rogers/FR-4 hybrid

- High-speed lanes: 28 Gbps differential pairs with length matching

- Memory interface: Fly-by topology with on-die termination

- Clock distribution: Redundant PLLs with jitter <100 fs

- Thermal design: Vapor chamber cooling for processor IC

This example demonstrates the level of engineering detail required to design high-speed circuits for 5G.

Future Trends in High-Speed 5G Circuit Design

Looking forward, 5G and beyond (6G) will require even higher speeds and integration. Key trends include:

- Silicon photonics for optical interconnects

- Chiplet-based architectures with standardized interposers

- AI-assisted design automation for SI/PI optimization

- Wide bandgap semiconductors (GaN, SiC) for efficient RF front ends

- Ultra-thin flexible PCBs for wearable 5G devices

These advancements will shape the next generation of communication infrastructure and devices.

Conclusion

To design high-speed digital circuits for 5G applications, engineers must integrate expertise in pcb design, signal integrity, power delivery, thermal management, packaging, and EMC compliance. As frequencies increase and data rates exceed 100 Gbps, the line between digital and RF design becomes blurred. Success depends on accurate simulation, proper material selection, and careful PCB layout strategies. With the right methods, engineers can build robust 5G systems that deliver reliable performance across consumer devices, infrastructure, and industrial IoT.