In the modern industrial landscape, electrical generators are vital assets, ensuring uninterrupted power supply for various applications. However, like all machinery, generators are susceptible to failures, which can result in costly downtime and repair expenses. Traditional methods of monitoring and diagnosing problems in generators often involve periodic inspections, which may miss early signs of failure. With advancements in artificial intelligence (AI) and sensor technology, it is now possible to continuously monitor the health of electrical generators and predict potential failures before they occur. This article explores how AI can be used to diagnose problems with electrical generators, focusing on the use of accelerometers and neural networks for real-time vibration analysis.

The Importance of Vibration Monitoring in Electrical Generators

Vibration is one of the most critical indicators of the health of rotating machinery, including electrical generators. Abnormal vibrations often signify mechanical issues such as imbalance, misalignment, bearing failures, or looseness. Early detection of these issues is crucial to preventing catastrophic failures. Traditionally, vibration analysis has been performed periodically, but with the advent of AI and continuous monitoring technologies, it is now possible to diagnose problems in real-time.

Continuous Vibration Monitoring with Accelerometers

An accelerometer is a sensor that measures the acceleration of a component in a specific direction. When attached to an electrical generator, an accelerometer can continuously monitor the vibrations of the motor in multiple axes (e.g., X, Y, and Z). This continuous data collection is essential for capturing the dynamic behavior of the generator, including transient events that may be missed during periodic inspections.

Precise accelerometers, capable of detecting minute changes in vibration, are mounted on key points of the generator. These sensors capture real-time data on the motor’s vibration in all three axes. The raw data collected by the accelerometers is then subjected to further analysis to extract meaningful insights.

Fast Fourier Transform (FFT) for Frequency Spectrum Analysis

One of the most effective ways to analyze vibration data is through Fast Fourier Transform (FFT). FFT is a mathematical algorithm that converts time-domain signals (e.g., acceleration data) into frequency-domain signals. This transformation allows us to observe the frequency spectrum of the vibrations, revealing the different frequency components present in the signal.

In a normal operating condition, the frequency spectrum of a generator’s vibration will exhibit specific patterns or peaks corresponding to the natural frequencies of the system and the operational speed of the motor. However, when a mechanical issue arises, it introduces additional frequency components into the spectrum. For example, bearing faults often manifest as high-frequency vibrations, while misalignment can cause harmonic frequencies to appear in the spectrum.

By continuously performing FFT on the real-time accelerometer data, it is possible to track changes in the frequency spectrum over time. This ongoing analysis is crucial for identifying early signs of mechanical issues before they escalate into full-blown failures.

Using Neural Networks for Failure Prediction

While FFT provides valuable insights into the frequency spectrum of the vibrations, interpreting these spectra to diagnose specific issues can be challenging, especially when dealing with large volumes of data. This is where AI, particularly neural networks, comes into play.

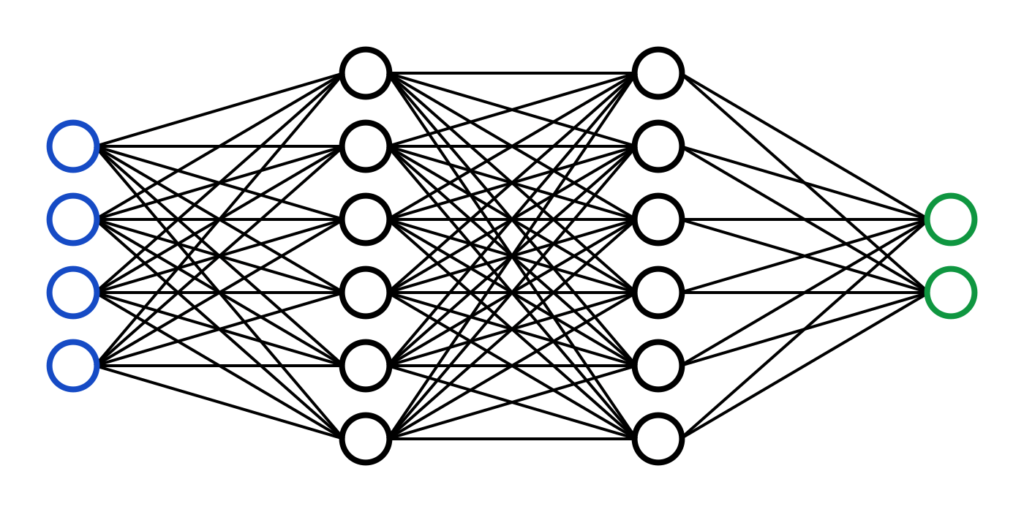

A neural network is a type of machine learning model that can learn patterns from data. In the context of generator diagnostics, a neural network can be trained to recognize the frequency spectrum patterns associated with normal operation and various types of failures. The training process involves feeding the neural network with labeled data—vibration spectra from both healthy generators and those with known faults.

Once trained, the neural network can continuously analyze new vibration data in real-time. The network compares the incoming frequency spectra with the learned patterns and assesses whether the current vibration profile is indicative of a specific failure. If the neural network detects a pattern that matches a known fault, it can alert the maintenance team, allowing them to take preemptive action before the failure progresses.

Continuous Background Failure Prediction

One of the significant advantages of using AI for generator diagnostics is the ability to perform continuous background failure prediction. As the generator operates, the neural network continuously monitors the vibration data without requiring human intervention. This background monitoring ensures that even the most subtle signs of failure are detected early.

For example, if a bearing in the generator begins to wear out, the vibration spectrum may show an increase in high-frequency components. The neural network, having learned the pattern associated with bearing wear, will recognize this change and flag it as a potential issue. The maintenance team can then inspect the bearing and replace it if necessary, preventing a more severe failure that could lead to extensive downtime.

Advantages of AI-Driven Diagnostics

Implementing AI-driven diagnostics for electrical generators offers several advantages over traditional methods:

1. Early Detection of Failures:

AI can detect early signs of mechanical issues, allowing maintenance teams to address problems before they lead to costly failures.

2. Continuous Monitoring:

Unlike periodic inspections, AI-driven diagnostics provide continuous monitoring, ensuring that no transient events or gradual changes go unnoticed.

3. Automated Analysis:

Neural networks can process vast amounts of data in real-time, automating the analysis process and reducing the need for manual interpretation of vibration spectra.

4. Improved Reliability:

By predicting failures before they occur, AI-driven diagnostics improve the reliability and availability of electrical generators, reducing the risk of unexpected downtime.

5. Cost Savings:

Early intervention and continuous monitoring can lead to significant cost savings by minimizing the need for emergency repairs and extending the lifespan of critical components.

Conclusion

The integration of AI into the diagnostics of electrical generators represents a significant leap forward in predictive maintenance. By leveraging accelerometers for continuous vibration monitoring and using FFT for frequency spectrum analysis, it is possible to capture detailed insights into the health of a generator. Neural networks further enhance this capability by learning to recognize patterns associated with specific failures, enabling continuous background failure prediction. This approach not only improves the reliability of electrical generators but also offers substantial cost savings and operational efficiency. As AI technology continues to advance, its application in generator diagnostics will become increasingly sophisticated, paving the way for even more proactive and precise maintenance strategies.