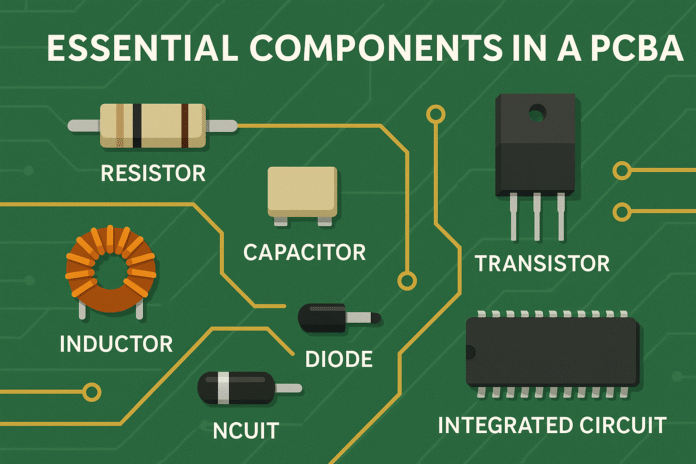

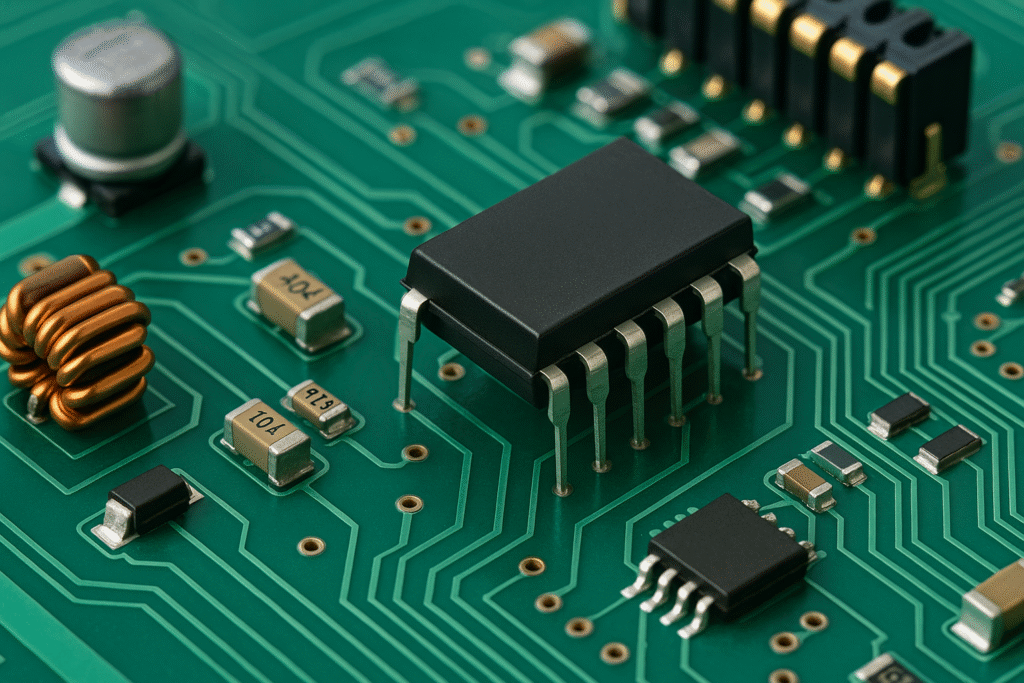

Understanding the essential components in a PCBA (Printed Circuit Board Assembly) is fundamental for electronic engineers, manufacturers, and product developers. PCBA refers to a finished circuit board populated with all required parts, enabling it to perform its intended functions. From resistors to integrated circuits and connectors, each component plays a critical role in performance and reliability. Careful selection, sourcing, and placement—backed by optimized pcb design—ensure that assembled boards meet both functional and regulatory standards. This guide explores the most important PCBA components, their functions, and their role in modern electronics.

Passive Components: Resistors, Capacitors, Inductors

Resistors

Resistors limit current and divide voltages. They are among the most common elements in a PCBA. Available as surface-mount or through-hole, resistors are chosen based on resistance value, tolerance, and power rating. Special resistors include precision, wirewound, and variable types. Placement in pcb design affects noise levels and heat dissipation.

Capacitors

Capacitors store and release energy, filter signals, and stabilize voltage. They are essential for smoothing power supply lines, decoupling ICs, and creating oscillators. Key types include ceramic, electrolytic, tantalum, and film capacitors. Their placement near integrated circuits reduces voltage ripple and noise.

Inductors

Inductors store energy in magnetic fields, block high-frequency noise, and form filters with capacitors. They are critical in DC-DC converters, RF circuits, and EMI suppression. Toroidal, solenoid, and multilayer chip inductors are commonly used in PCBA.

Active Components: Transistors, Diodes, ICs

Transistors

Transistors amplify signals and switch currents. They form the backbone of digital logic, power regulation, and RF circuits. MOSFETs and BJTs are widely used in controllers, motor drivers, and power supplies. Proper heat sinking and pcb trace width ensure reliability.

Diodes

Diodes allow current to flow in one direction, protecting circuits and rectifying signals. Common types include rectifier diodes, Schottky diodes for high-speed switching, and Zener diodes for voltage regulation. Placement near power input prevents reverse polarity damage.

Integrated Circuits (ICs)

ICs combine multiple electronic functions into compact packages. Microcontrollers, DSPs, power regulators, and op-amps are all IC-based. They require precise pad layout, decoupling capacitors, and thermal relief in pcb design. Fine-pitch ICs such as BGAs require X-ray inspection for assembly verification.

Substrate Materials and Solder Types

The base material and solder used in PCBA influence electrical, mechanical, and thermal properties.

Substrate Materials

- FR-4: Standard fiberglass epoxy, widely used in consumer and industrial boards.

- Polyimide: Flexible, heat-resistant substrate for aerospace and medical wearables.

- Rogers laminates: Low-loss, high-frequency material for RF and 5G applications.

Solder Types

- Lead-based solder: Traditional option, easy to work with but restricted by RoHS.

- Lead-free solder: Tin-silver-copper alloys meet modern compliance standards.

- Special solders: Alloys with bismuth or indium for high-reliability applications.

Solder joints must be carefully managed to avoid voids, cracks, or weak connections.

Connectors and Interconnects

No PCBA functions alone—connectors allow integration into larger systems.

- Board-to-board connectors: Enable stacking or modular expansion.

- Wire-to-board connectors: Used for external power and signal input.

- Edge connectors: Provide removable card-to-motherboard interfaces.

- High-speed connectors: Handle GHz-level data transfer in servers and telecom systems.

Connectors are critical design points, as mechanical stress and insertion cycles affect lifespan.

Mounting Techniques: Surface Mount vs. Through-Hole

Surface Mount Technology (SMT)

SMT dominates modern PCBA because it allows high-density designs, smaller footprints, and automated assembly. Components are soldered directly onto copper pads. SMT is ideal for smartphones, laptops, and IoT devices.

Through-Hole Technology (THT)

Through-hole components are inserted into drilled holes and soldered on the opposite side. They provide stronger mechanical bonds and are preferred for connectors, large capacitors, and transformers.

Mixed Assembly

Many PCBs use both SMT and THT for balance. For example, a power supply may use SMT ICs but through-hole inductors and connectors.

Power Supply Components in PCBA

Power supply stability is critical for any circuit. Key components include:

- Voltage regulators: Ensure stable supply regardless of load fluctuations.

- DC-DC converters: Step-up or step-down voltage efficiently.

- Transformers: Provide isolation and voltage conversion in power modules.

These components require thick copper traces, careful placement, and heat dissipation techniques.

Protection Components

To improve reliability, PCBAs include protective devices:

- Fuses: Provide overcurrent protection.

- TVS diodes: Protect against electrostatic discharge (ESD).

- NTC thermistors: Limit inrush current during startup.

These devices prevent damage from surges, thermal stress, and misuse.

Importance of PCB Design for Component Integration

Efficient pcb design ensures that all components work as intended. Key design rules include:

- Proper grounding and decoupling for ICs.

- Trace width calculations for current capacity.

- Separation of analog and digital signals to reduce interference.

- Thermal reliefs for heat-sensitive components.

- Component spacing to allow for automated placement and rework.

Design for manufacturability (DFM) ensures that designs can be built reliably and affordably.

Inspection and Testing of PCBA Components

Even with precise assembly, testing is essential:

- AOI (Automated Optical Inspection) detects missing or misaligned components.

- X-ray inspection verifies hidden joints under BGAs.

- ICT (In-Circuit Testing) checks resistance, capacitance, and signal flow.

- Functional testing ensures the assembled board performs correctly in real-world conditions.

This multi-step inspection guarantees product reliability before shipping.

Applications of PCBA Components

Different industries prioritize different components:

- Consumer electronics: Miniaturized SMT parts dominate.

- Automotive: High-reliability connectors, fuses, and rugged ICs.

- Medical devices: Low-noise components, specialized substrates, and strict testing.

- Telecommunications: High-frequency laminates and precision connectors.

The choice of components depends on cost, reliability, and regulatory compliance.

Future Trends in PCBA Components

The future will bring:

- Smaller, more efficient ICs integrating multiple functions.

- Flexible and stretchable substrates for wearables and implants.

- Gallium nitride (GaN) transistors for efficient power management.

- 3D packaging to increase density without increasing footprint.

- AI-enhanced pcb design tools for smarter component placement.

These innovations will expand the capabilities of PCBA across industries.

Conclusion

Understanding the essential components in a PCBA provides insight into how electronics are designed, built, and optimized. From resistors and capacitors to ICs, connectors, and protective devices, each part has a role to play in ensuring performance and reliability. Substrates and solder choices also affect manufacturing quality, while proper pcb design guarantees smooth assembly and long-term durability. As technology advances, PCBA components will continue to shrink, integrate, and evolve, enabling smarter and more powerful devices for the future.