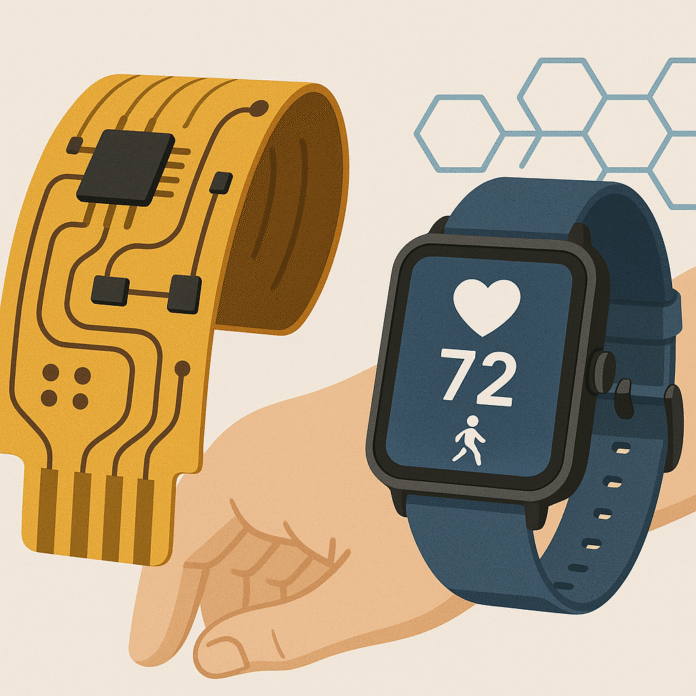

The field of flexible and wearable electronics is redefining how we interact with technology. These advancements are no longer confined to prototypes or futuristic concepts—they’re now part of everyday applications in healthcare, fitness, smart textiles, and industrial monitoring. The synergy between materials science, miniaturized hardware, and intelligent software allows wearable technology to function in real-world, dynamic environments. In this context, pcb design becomes more vital than ever, as flexible circuits require innovative approaches for signal integrity, power management, and form factor optimization.

Flexible Electronics

Flexible electronics, also known as flex circuits, are characterized by their ability to bend, fold, twist, and stretch without losing functionality. Unlike traditional rigid PCBs, these circuits are built on flexible substrates such as polyimide, PET, or other thin polymer films. These materials allow devices to conform to various shapes, enabling integration into clothing, skin patches, or curved surfaces.

The applications of flexible electronics span a wide range—from foldable smartphones to rollable displays, smart bandages that monitor healing, and flexible solar panels. Their lightweight nature and durability also make them ideal for environments where rigidity would pose limitations, such as aerospace or implantable medical devices.

The design of flexible electronics introduces new challenges for engineers. Mechanical stress from bending can lead to microfractures or delamination if the circuit layout or material selection is poor. Engineers must consider bend radius, trace layout, and component anchoring. Thermal management is also a concern due to the compact and often enclosed nature of flexible assemblies.

Wearable Electronics Design

Wearable electronics extend the capabilities of flexible circuits by embedding them into devices worn on the body. These include smartwatches, fitness trackers, AR glasses, smart clothing, and even biosensors integrated into textiles. Wearables require components that are low power, lightweight, comfortable, and capable of wireless communication.

Designing for wearables involves a multi-disciplinary approach. Electrical, mechanical, and materials engineers collaborate with biomedical experts and fashion designers. Battery life is a major design constraint, as wearables must operate for extended periods without recharging. Energy harvesting from body movement, solar power, or thermoelectric generators is often explored to supplement power.

Human-centric design is critical. Devices must not irritate the skin, cause discomfort, or be overly noticeable. Medical-grade adhesives or soft enclosures are used to attach electronics directly to the skin. Waterproofing and breathability are also essential for wearables used during physical activities.

Challenges in Flexible Electronics

Despite the many opportunities, the development and mass production of flexible and wearable electronics are not without difficulties. Key challenges include:

1. Material Limitations:

Finding substrates and conductive inks that can maintain electrical performance under mechanical stress is a major hurdle. Stretchable conductors, such as silver nanowires or graphene-based materials, are under research but are still not mainstream.

2. Durability and Reliability:

Repeated bending, sweat exposure, UV degradation, and mechanical wear can degrade performance over time. Testing for longevity under real-world conditions is more complex than with rigid devices.

3. Integration of Rigid Components:

While flexible substrates can accommodate many applications, components like batteries, chips, and sensors are still typically rigid. Hybrid integration techniques—embedding rigid islands on flexible substrates—are used to overcome this, but it adds complexity to the manufacturing process.

4. Signal Integrity and PCB Design Complexity:

High-speed data signals can degrade in flexible circuits if not properly managed. Signal reflections, EMI issues, and impedance mismatches require special attention during pcb design. Maintaining consistent trace geometry and separation across dynamic motion adds to the complexity.

5. Manufacturing Scalability:

Processes like screen printing, inkjet deposition, and roll-to-roll fabrication are still evolving to meet quality and yield standards suitable for mass production. Custom tooling and assembly also increase costs for small production runs.

Opportunities in Wearable Technology

Despite the challenges, the potential of wearable technology is massive. As sensors, microcontrollers, and wireless modules become smaller and more energy-efficient, new possibilities emerge:

1. Healthcare Monitoring:

Wearables can continuously track vital signs such as heart rate, blood oxygen levels, temperature, and hydration. This real-time data can be used for early diagnosis, chronic condition management, or post-surgery monitoring. Smart patches and textile-integrated biosensors are already being adopted in hospitals and home care.

2. Fitness and Sports Performance:

Athletes benefit from wearables that monitor muscle fatigue, hydration, posture, and even biomechanics. These insights help optimize training and prevent injuries. Smart insoles, posture correctors, and connected sportswear are becoming more common among professionals and amateurs alike.

3. Safety and Industrial Applications:

In industrial settings, wearable devices track worker fatigue, detect hazardous gas exposure, or monitor location for safety purposes. Construction helmets with embedded sensors or smart vests with haptic feedback are now used in high-risk environments.

4. Smart Textiles:

The integration of electronics into fabrics brings comfort and utility. Heated jackets, color-changing clothes, and clothing that responds to environmental stimuli offer both functionality and personalization.

5. Accessibility and Assistance Devices:

For people with disabilities, wearable devices like haptic gloves, auditory augmentation tools, or visual aid glasses provide enhanced interaction with the world around them. AI-powered voice interfaces and environmental sensors make such wearables more intuitive and effective.

Future of Flexible and Wearable Electronics

The future of flexible and wearable electronics lies in their seamless integration into daily life, offering convenience, health insights, and enhanced productivity. As artificial intelligence, 5G, and edge computing evolve, these devices will shift from passive data collectors to proactive systems capable of real-time decision-making.

Advancements in nanomaterials, such as carbon nanotubes and graphene, promise thinner, more flexible, and more conductive layers. These materials can be used in transistors, antennas, and sensors, pushing the limits of current technology. The development of stretchable batteries and flexible OLED displays will enable entirely soft devices.

Wearable devices will also become more personalized, adapting to individual biometrics and preferences. Smart rings, implantables, and augmented reality interfaces are on the horizon. With increased miniaturization, even accessories like earrings or contact lenses may become carriers of smart functionality.

Regulatory and Ethical Considerations

As wearable and flexible electronics become more embedded in our lives, concerns about data privacy, ethical use, and health risks grow. Regulatory frameworks must adapt to new technologies, especially in healthcare applications. It is essential to safeguard user data, secure wireless communication, and provide transparency in data usage.

Biocompatibility is another key area. Long-term skin contact or implantation requires materials that are non-toxic, non-irritating, and hypoallergenic. Regulatory bodies like the FDA and CE have been increasing oversight of wearable health tech, requiring clinical validation and data transparency.

Conclusion

Flexible and wearable electronics are no longer emerging—they are actively reshaping the technological landscape. They combine the benefits of miniaturized electronics with the adaptability of soft materials, offering users a natural and continuous interaction with technology. From medical diagnostics to daily convenience, the impact of these technologies is profound.

Designers and engineers are challenged to rethink pcb design, system integration, and user comfort in ways that depart from traditional electronics. The future will belong to systems that are not only intelligent and efficient but also soft, wearable, and unobtrusive.

As materials science and fabrication techniques advance, and as regulations become clearer, flexible and wearable electronics will become ubiquitous—providing innovation not just on screens and desks, but worn across our bodies and built into our environments.