Printed Circuit Boards (PCBs) are at the heart of nearly all modern electronics, from smartphones and laptops to medical devices and industrial equipment. Ensuring their functionality and reliability is crucial, which is why PCB testing is a vital step in the manufacturing process. Among various methods available, Flying Probe Testing (FPT) stands out as a cost-effective and flexible solution for PCB testing, especially during prototyping and low-volume production.

Understanding Flying Probe Testing

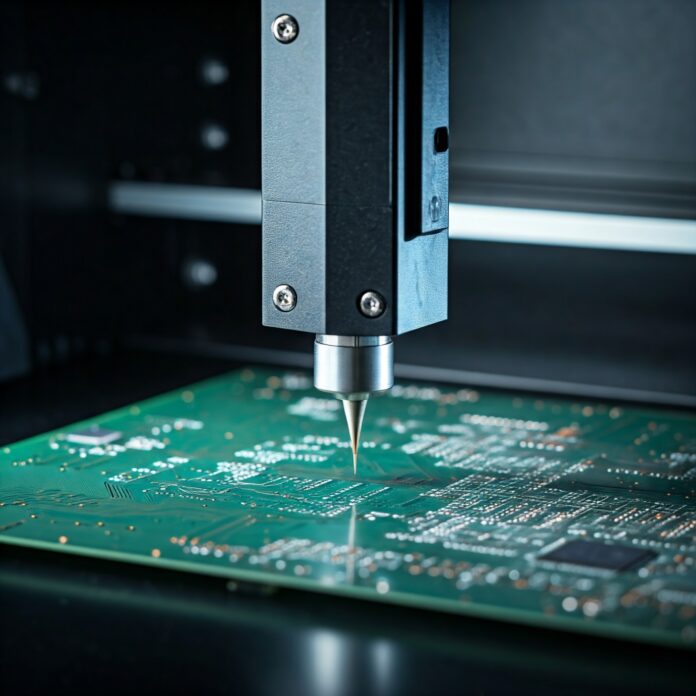

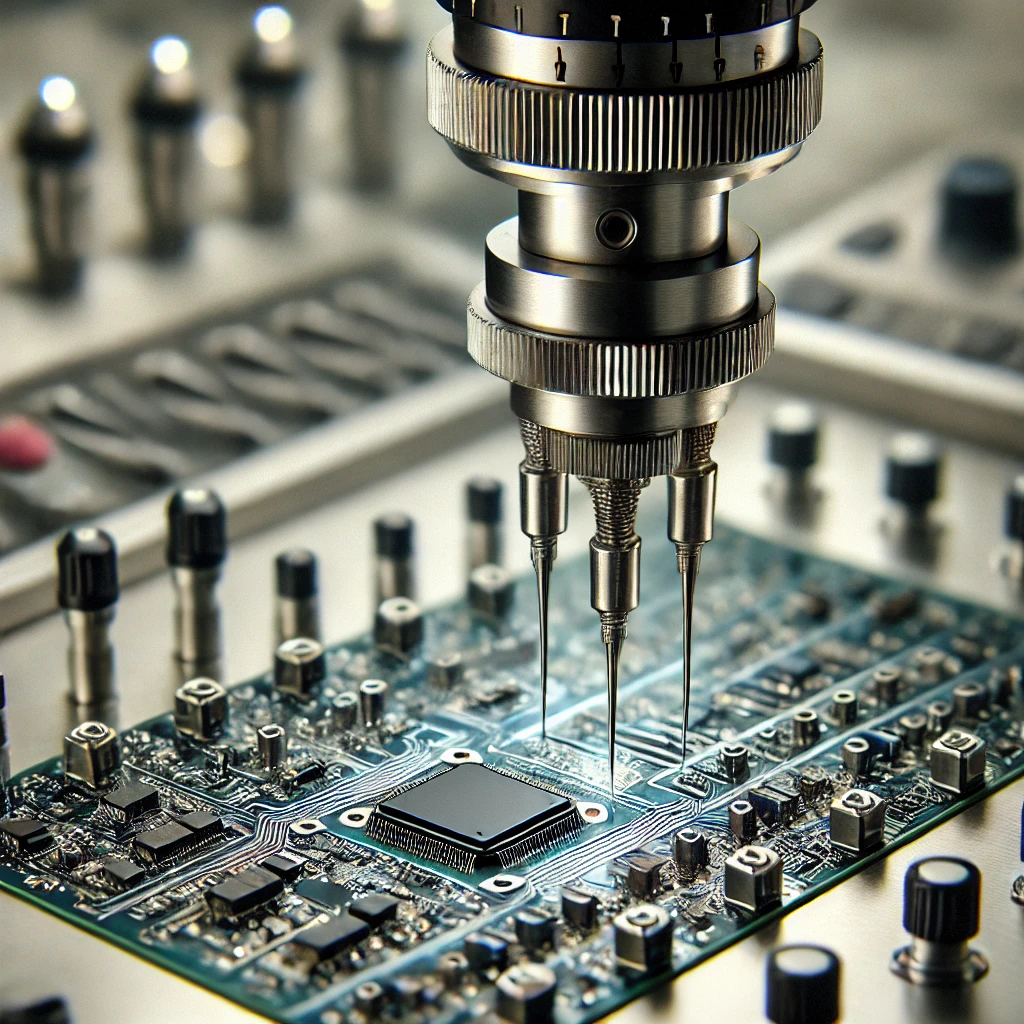

Flying Probe Testing is a type of automated testing that uses multiple probes mounted on movable arms to test the electrical connections and components of a PCB. Unlike traditional In-Circuit Testing (ICT), which requires a custom-made fixture for each board design, FPT does not involve any dedicated fixtures. Instead, the probes “fly” across the board, guided by software and precise servo mechanisms, to test various points on the PCB.

This approach offers several advantages:

- No Fixture Costs: Since no custom fixtures are required, FPT significantly reduces initial setup costs.

- Quick Setup: Test programs can be created quickly based on design data, making it ideal for prototypes and short production runs.

- Flexibility: FPT can accommodate design changes without the need to modify physical hardware.

- Comprehensive Testing: It can test for open circuits, shorts, resistance, capacitance, and even component orientation.

The Process of Flying Probe Testing

The FPT process begins with importing the PCB design data, including Gerber files and the Bill of Materials (BOM). The test program is then created, specifying the test points, component values, and expected outcomes.

Once the test program is ready, the PCB is placed on the testing platform. The probes, controlled by precise motors, move across the board to contact specific test points. Measurements are taken and compared to the expected values. Any discrepancies are flagged for further investigation.

FPT systems often incorporate advanced features such as:

- High-Speed Probing: Modern systems can test thousands of points per minute.

- Optical Inspection: Cameras can verify component placement and orientation.

- Parametric Testing: Allows for testing of analog components and measuring parameters like resistance and capacitance.

Advantages of Flying Probe Testing

1. Cost Efficiency

One of the most significant advantages of FPT is its cost efficiency. Since it eliminates the need for custom fixtures, it is particularly advantageous for low-volume production and prototyping. In contrast, traditional ICT systems require expensive and time-consuming fixture fabrication, which is only cost-effective for high-volume production.

2. Fast Turnaround

FPT’s quick setup process means that test programs can be created and executed within hours. This rapid turnaround is crucial for prototyping and design validation, where time-to-market is often a critical factor.

3. Flexibility and Scalability

The flexibility of FPT makes it an ideal choice for testing PCBs with frequent design changes. Unlike ICT, which requires new fixtures for each design update, FPT programs can be easily modified. This scalability also extends to testing different board sizes and complexities without significant hardware changes.

4. Comprehensive Coverage

FPT offers extensive test coverage, including:

- Testing for open and short circuits

- Measuring resistance, capacitance, and inductance

- Verifying component orientation and polarity

- Testing connectors and interfaces

Additionally, some advanced FPT systems can perform boundary scan testing and functional testing.

Limitations of Flying Probe Testing

While FPT offers numerous benefits, it also has some limitations:

- Slower Testing Speed: Compared to ICT, FPT is slower for high-volume production due to its sequential nature.

- Limited High-Frequency Testing: FPT is less effective for testing high-frequency components and signals.

- Mechanical Wear and Tear: The probes and motors are subject to mechanical wear, requiring regular maintenance.

Despite these limitations, FPT remains a go-to solution for scenarios where flexibility, cost efficiency, and quick setup are more critical than high-speed testing.

Applications of Flying Probe Testing

FPT is widely used in various industries and scenarios, including:

- Prototyping: To validate designs before mass production.

- Low-Volume Production: For niche products or specialized applications.

- Design Verification: To identify and fix design flaws early in the development cycle.

- Failure Analysis: To diagnose issues in defective PCBs.

Future Trends in Flying Probe Testing

As technology advances, FPT systems are becoming more sophisticated. Some emerging trends include:

- Higher Speed and Precision: New systems are incorporating faster motors and more accurate probes to reduce testing time.

- Integration with AI and Machine Learning: These technologies can optimize test programs and identify patterns in test data to predict potential failures.

- Enhanced Functional Testing: FPT systems are increasingly capable of performing more complex functional tests, bridging the gap between electrical and functional testing.

- Improved Automation: Integration with automated material handling systems allows for seamless testing in production lines.

Choosing the Right Testing Method

The choice of a PCB testing method depends on several factors, including production volume, budget, and specific testing requirements. While ICT is more suitable for high-volume production, FPT offers unmatched flexibility and cost savings for prototyping and low-volume runs. Combining FPT with other methods like Automated Optical Inspection (AOI) can further enhance test coverage and reliability.

Conclusion

Flying Probe Testing has established itself as a cost-effective and versatile solution for PCB testing. Its flexibility, quick setup, and comprehensive coverage make it an ideal choice for prototypes, low-volume production, and scenarios requiring frequent design changes. While it may not replace traditional testing methods for high-volume manufacturing, it complements them, offering manufacturers a reliable way to ensure PCB quality and functionality.

As technology continues to evolve, FPT systems are expected to become even more efficient and capable, further cementing their role in modern electronics manufacturing. By leveraging the advantages of FPT, manufacturers can reduce costs, improve turnaround times, and deliver reliable products to market faster.