With rapid advancement in technology, fast speed and efficiency in every electronic device are increasing demand for high-frequency PCBs in high-speed systems. These special printed circuit boards represent an integral part of today’s electronics due to fast data transmission, enhanced signal integrity, and thermal management.

We will discuss in this article high-frequency PCBs, their very important function in telecommunications, automotive and aerospace, and consumer electronics, especially with the recent rise of 5G, IoT, and advanced computing. We are going to look in great detail at the challenges in designing these PCBs: electromagnetic interference management, minimization of signal loss, and PCB design trends..

We will also be covering the essential PCB manufacturing issues like material selection, board layout, and fabrication techniques related to low-loss dielectric materials, all of which are crucial in making PCBs efficient and reliable. And lastly, we will explore the latest trends within high-frequency PCB technology, focusing on their increasingly important role they currently play in enabling innovative applications in the electronics industry.

What are High-Frequency PCBs?

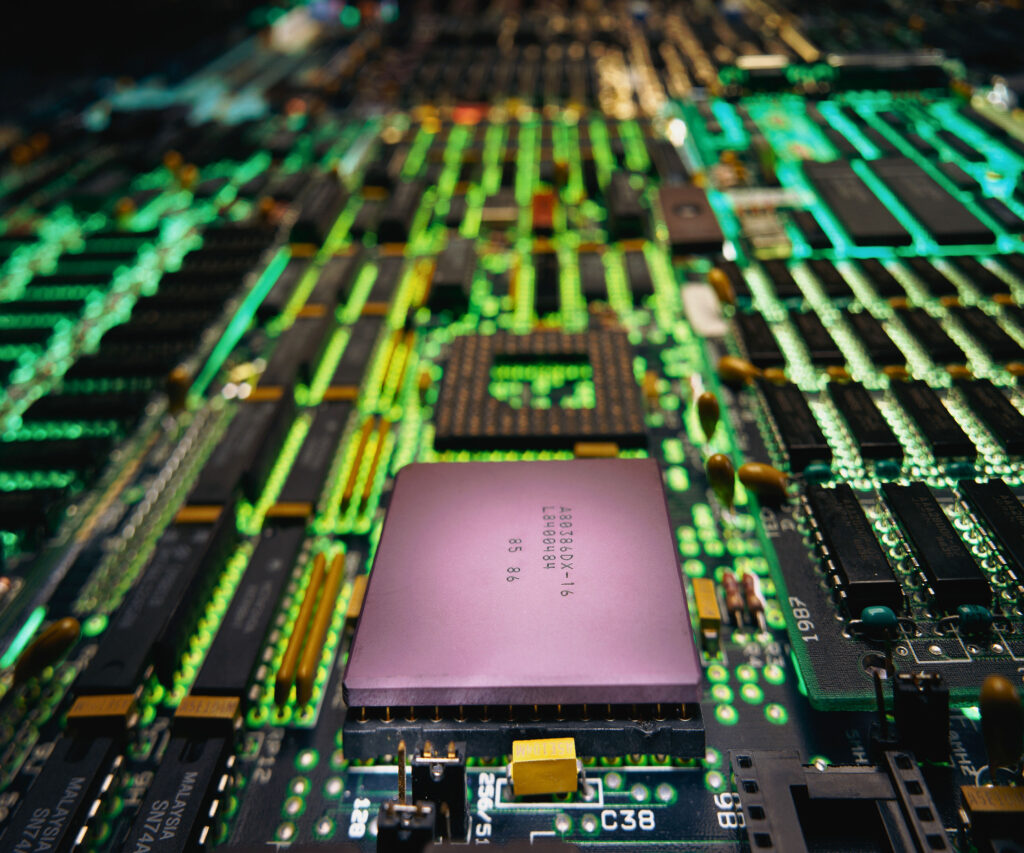

High-frequency PCBs are specialized circuit boards designed to operate at microwave frequencies, typically above 1 GHz. These frequencies are critical in various applications, including telecommunications, radar systems, satellite communications, and a multitude of consumer electronics. Unlike standard PCBs, which may be built from conventional materials, high-frequency PCBs require advanced substrates that can handle rapid signal transitions without significant degradation or loss.

Key Characteristics of High-Frequency PCBs

Material Composition:

High-frequency PCBs are typically made from materials such as Rogers, Taconic, and Arlon, known for their low dielectric constants and low loss tangent. These materials minimize signal loss and improve performance at high frequencies.

Impedance Control:

High-frequency PCBs require precise impedance control to ensure signal integrity. Impedance mismatch can cause reflections and lead to data loss, so careful design is crucial.

Layer Count:

High-frequency applications often necessitate increased layer counts to manage routing and signal paths efficiently. Multilayer PCBs can accommodate complex designs while minimizing interference.

Thermal Management:

Devices operating at high frequencies generate significant heat. Effective thermal management through vias, heat sinks, and thermal materials is vital to maintaining performance and reliability.

The Importance of High-Frequency PCBs in High-Speed Electronics

As industries strive for greater performance, high-frequency PCBs have become increasingly important in high-speed electronics. Here are several reasons why:

1. Increasing Data Transfer Rates

The explosion of data in our digital world mandates higher data transfer rates. High-frequency PCBs enable this by supporting faster clock speeds and greater bandwidth, essential in networking equipment, data centers, and media streaming devices.

2. Enhanced Performance in Telecommunications

High-frequency PCBs are quintessential in telecommunications systems. They are used in base stations, antennas, and other critical components that facilitate wireless communication, allowing for clearer signals and expanded network coverage.

3. Reliability in Automotive Systems

With the rise of autonomous vehicles and advanced driver-assistance systems (ADAS), high-frequency PCBs are integral to the operation of radar and LIDAR systems. These technologies rely on high-speed signal processing capabilities for real-time data analysis and decision-making.

4. Optimized Signal Integrity

In high-speed electronic systems, maintaining signal integrity is paramount. High-frequency PCBs, designed with meticulous attention to factors like trace width, spacing, and layer stacking, provide optimal paths for signal transmission, reducing crosstalk and electromagnetic interference (EMI).

PCB Design for High-Frequency Applications

Designing a high-frequency PCB involves a unique set of challenges and considerations distinct from traditional PCB design. Here are some essential aspects to consider:

1. High-Frequency Signal Path Design

When designing for high frequencies, every aspect of the signal path matters. Designers must account for trace width, length, and termination. It’s crucial to maintain a controlled impedance throughout the PCB layout, typically 50 ohms for coaxial transmission lines.

2. Layer Stack-Up Configuration

Careful planning of the layer stack-up is vital to reduce unwanted electromagnetic interference. Multi-layer PCB designs can help isolate signal layers from power and ground planes, thereby improving performance.

3. Via Design and Placement

Vias can introduce significant inductance and affect signal integrity. Microvias or buried vias often emerge as preferred options to minimize the adverse effects of traditional vias in high-frequency applications.

4. Simulation and Modeling

Before moving to manufacturing, it’s essential to simulate the PCB design using electromagnetic field simulation tools. These tools provide insights into potential signal issues, enabling designers to make necessary adjustments.

5. Testing and Prototyping

Prototyping enables designers to test the PCB under real-world conditions. High-speed testing methodologies, such as TDR (Time Domain Reflectometry) and S-parameter testing, help evaluate the performance of the prototype, ensuring it meets design specifications.

The Manufacturing of High-Frequency PCBs

Producing high-frequency PCBs requires advanced manufacturing techniques and strict quality control measures. Here are several considerations during the manufacturing phase:

1. Quality Material Selection

Choosing high-quality materials is necessary to achieve optimal performance. Manufacturers should source materials that meet the specifications for dielectric constant, loss tangent, and thermal conductivity.

2. Precision Fabrication Techniques

High-frequency PCBs often necessitate micro-fabrication techniques, including laser drilling and fine-line technology, to achieve the necessary precision in trace widths and spacing.

3. Surface Finish Options

The finish of the PCB surface can affect solderability and signal integrity. Manufacturers can choose from various surface finishes, including ENIG (Electroless Nickel Immersion Gold), which offers excellent performance for high-frequency applications.

4. Stringent Testing Protocols

To ensure reliability, high-frequency PCBs undergo rigorous testing protocols, including visual inspections, electrical testing, and thermal cycling tests. These assessments ensure that the PCB can withstand operational stresses.

Future Trends in High-Frequency PCBs

As technology advances, high-frequency PCBs are expected to evolve as well. Here are some trends that are likely to influence the future landscape:

1. Miniaturization of Components

As devices become smaller, the demand for compact, high-frequency PCBs will increase. Manufacturers will need to innovate in design and fabrication methods to accommodate this trend.

2. Integration with 5G Technology

The rollout of 5G technology is driving innovation in high-frequency PCBs. These boards must support the higher frequencies and increased bandwidth required for 5G applications.

3. Development of New Materials

Research into new substrate materials promises to yield options that enhance performance at even higher frequencies while reducing costs.

4. Sustainability Initiatives

As the electronics industry seeks to reduce its environmental impact, the development of sustainable materials and manufacturing processes for high-frequency PCBs will become increasingly important.

Conclusion

High-frequency printed circuit boards play a critical role in high-speed electronics and are essential for various applications in today’s digital world. From telecommunications to automotive systems, these specialized PCBs ensure that signals are transmitted efficiently and reliably, meeting the high demands of modern technology. By understanding the unique aspects of PCB design and manufacturing that cater to high-frequency applications, engineers and designers can create efficient, high-performance electronic devices that continue to push the boundaries of innovation. As we move forward, the evolution of high-frequency PCBs will undoubtedly shape the future of electronics, enabling faster, smarter, and more integrated systems.