Motor speed is a critical parameter in various applications, from industrial machinery to household appliances. Whether you’re dealing with an electric motor in a fan, a conveyor belt, or an electric vehicle, understanding how to measure motor speed is essential for ensuring the proper functioning and efficiency of the equipment. Motor speed measurement also helps in diagnosing issues, improving performance, and preventing mechanical failures.

In this article, we will explore the different methods and tools used to check the speed of a motor, the importance of motor speed measurement, and the factors that influence motor speed.

Importance of Measuring Motor Speed

Motor speed, typically measured in revolutions per minute (RPM), is crucial for determining how well the motor is performing relative to its designed specifications. In both industrial and consumer applications, maintaining the correct motor speed is essential for the following reasons:

Efficiency:

A motor operating at the optimal speed is more energy-efficient. Deviations from the correct speed can lead to energy waste or overheating.

Performance:

For many machines, performance is directly related to motor speed. If a motor is running too fast or too slow, it can affect the machine’s output and quality of work.

Safety:

A motor that operates outside of its intended speed range can pose safety hazards, especially in high-speed machinery. Measuring motor speed helps in ensuring safety protocols are maintained.

Maintenance:

Regular speed checks can help identify wear and tear or potential problems in motor components, allowing for timely maintenance and preventing costly breakdowns

Factors That Affect Motor Speed

Several factors influence the speed of a motor, and understanding these factors is key to accurate speed measurement:

Load:

The load applied to the motor can affect its speed. As the load increases, the motor may slow down if it is unable to provide the necessary torque to maintain the set speed.

Voltage and Current:

For electrical motors, the supply voltage and current are directly linked to the motor’s speed. Insufficient voltage can cause the motor to run slower, while excessive voltage can damage the motor and cause erratic speed.

Type of Motor:

Different types of motors operate with different speed characteristics. For example, a DC motor’s speed is typically proportional to the voltage applied, while the speed of an AC motor is influenced by the frequency of the power supply.

Mechanical Friction and Wear:

Over time, mechanical parts such as bearings and brushes can wear out, causing friction that slows down the motor.

Environmental Factors:

Temperature, humidity, and dust can affect motor performance and speed. For example, excessive heat may cause components to expand or overheat, affecting motor speed.

Methods to Measure Motor Speed

There are several methods to measure the speed of a motor, each with its own advantages and suitability for specific applications. The choice of method depends on the type of motor, the accuracy required, and the available tools.

1. Tachometers

A tachometer is a widely used instrument for measuring motor speed. It can measure the speed in RPM by counting the number of revolutions in a given time period. There are two main types of tachometers: contact and non-contact.

- Contact Tachometer: This type of tachometer is placed in direct contact with the rotating part of the motor (usually the shaft). It measures the speed by counting the revolutions per minute based on physical contact. It’s generally accurate but can cause slight wear to the motor due to direct contact.

- Non-Contact Tachometer: This method uses a laser or optical sensor to measure the speed without any physical contact. A reflective marker is placed on the rotating part of the motor, and the tachometer uses light to detect each revolution. Non-contact tachometers are more accurate for high-speed applications and are ideal when physical contact is undesirable.

How to Use a Tachometer:

- For a contact tachometer, place the tip of the device against the center of the rotating motor shaft.

- For a non-contact tachometer, attach a reflective marker on the motor shaft and aim the laser at it from a safe distance.

- The device will display the speed in RPM.

2. Stroboscope

A stroboscope is another optical method to measure motor speed, particularly for motors that are difficult to access. It works by flashing a light at a high frequency that can be adjusted. When the flashing frequency matches the speed of the rotating motor, the rotating part appears stationary. This phenomenon is called the “strobe effect.”

How to Use a Stroboscope:

- Shine the stroboscope light on the motor shaft.

- Adjust the flashing frequency of the strobe light until the motor shaft appears to stop moving.

- The flashing frequency at which the motor appears stationary corresponds to the motor’s RPM.

Stroboscopes are advantageous because they are non-invasive and can be used on motors that are inaccessible for contact-based measurements. However, they require good visibility and a clear line of sight to the motor shaft.

3. Encoders

Encoders are electromechanical devices that convert mechanical motion into an electrical signal that can be interpreted to measure speed, position, and direction. Encoders can be attached to the motor shaft and used in applications requiring precise speed control.

There are two main types of encoders:

- Rotary Encoders: These are attached to the rotating motor shaft and measure the angle of rotation to calculate the speed.

- Linear Encoders: These measure linear motion but can be adapted for use with motors in certain applications.

Encoders are highly accurate and often used in automation, robotics, and CNC machinery.

How to Use an Encoder:

- Mount the encoder on the motor shaft.

- The encoder will generate a signal (pulse) for each increment of movement, which can be counted to calculate the speed.

- The speed in RPM can be calculated by determining the number of pulses per revolution and the time taken.

4. Hall Effect Sensors

Hall Effect sensors are widely used in brushless DC motors for speed measurement. These sensors detect the magnetic field changes as the motor shaft rotates, allowing them to calculate the speed based on the frequency of magnetic field pulses.

Hall Effect sensors are especially useful in applications where continuous and real-time motor speed monitoring is required, such as in automotive or industrial systems.

How to Use a Hall Effect Sensor:

- Attach the sensor to the motor, aligned with the rotor’s magnetic poles.

- The sensor will produce a digital signal proportional to the speed of the motor.

- This signal can then be processed to determine the speed in RPM.

5. Digital Multimeter (with Frequency Measurement Feature)

Some digital multimeters have a frequency measurement mode that allows them to measure the frequency of the AC voltage supplied to the motor. Since the speed of an AC motor is related to the frequency of the power supply, you can calculate the motor speed from the frequency.

For example, in synchronous motors, speed (RPM) can be calculated using the formula:

RPM=120×FrequencyNumber of Poles\text{RPM} = \frac{120 \times \text{Frequency}}{\text{Number of Poles}}RPM=Number of Poles120×Frequency

Where the number of poles is a fixed property of the motor.

How to Use a Multimeter:

- Set the multimeter to frequency measurement mode.

- Connect the multimeter probes to the motor terminals.

- Measure the frequency of the AC power supply and calculate the RPM using the above formula.

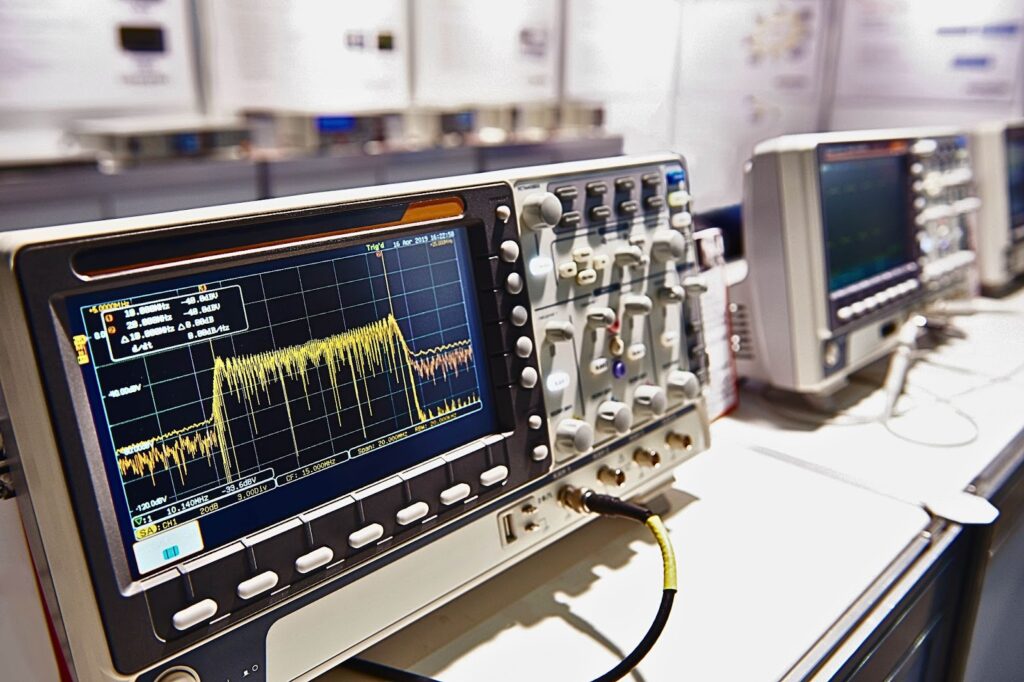

6. Oscilloscope

An oscilloscope can be used to measure motor speed by analyzing the electrical signal produced by the motor. For instance, in DC motors, the commutator produces a signal that can be visualized on the oscilloscope. The time interval between the peaks of the signal can be used to calculate the speed.

How to Use an Oscilloscope:

- Connect the oscilloscope probes to the motor’s electrical circuit.

- Observe the waveform on the oscilloscope display.

- Measure the time period of one complete cycle and calculate the RPM based on the waveform frequency.

Conclusion

Measuring motor speed is crucial for ensuring that motors are running efficiently, safely, and within their designed specifications. There are multiple methods available to measure motor speed, including tachometers, stroboscopes, encoders, Hall Effect sensors, digital multimeters, and oscilloscopes. The method you choose depends on the type of motor, the environment in which it operates, and the level of accuracy required.

By regularly checking motor speed and understanding how to use the appropriate tools, you can prevent mechanical failures, optimize performance, and extend the lifespan of the motor. Whether in industrial settings or home applications, monitoring motor speed is an important practice for maintaining the health of your equipment and systems.