In today’s highly competitive industrial landscape, unplanned downtime can lead to significant financial losses, productivity disruptions, and even safety hazards. Predictive maintenance (PdM) has emerged as a powerful paradigm shift, moving away from reactive “fix-it-when-it-breaks” approaches towards proactive, data-driven maintenance strategies. The integration of the Internet of Things (IoT) and machine learning (ML) has supercharged PdM, enabling real-time asset monitoring, intelligent fault prediction, and optimized maintenance scheduling.

IoT used to help with Condition Monitoring and now as we have huge cloud processing power, we can take Machine Learning (ML) to the cloud and the process of monitoring and predicting all achieved in one place.

Understanding the Fundamentals of Predictive Maintenance

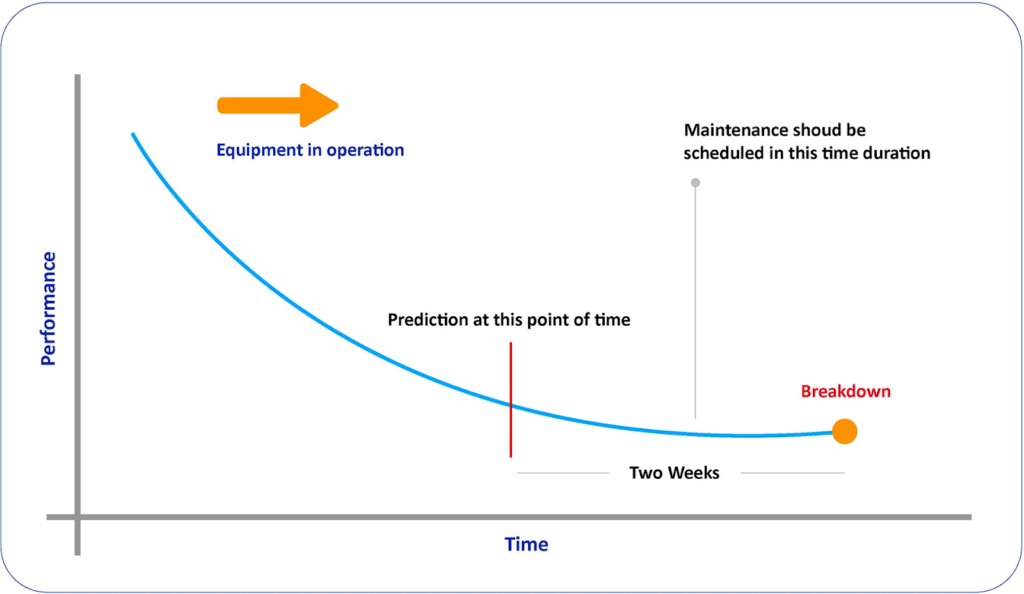

Predictive maintenance involves the use of sensors, data analytics, and machine learning models to continuously monitor the health of equipment and to predict potential failures before they occur.

This proactive approach aims to:

Minimize unplanned downtime

By identifying potential issues early, necessary repairs or replacements can be scheduled, preventing unexpected breakdowns.

Reduce maintenance costs

PdM helps avoid costly emergency repairs and extends asset lifespans, leading to overall cost savings.

Optimize resource allocation

Maintenance personnel and resources can be deployed more effectively based on data-driven insights.

Enhance safety

Preventing unexpected failures minimizes the risk of accidents and safety hazards in industrial environments.

The Role of IoT in Predictive Maintenance

IoT serves as the backbone of PdM. A network of sensors strategically placed on industrial assets collects various data types, including:

Vibration

Monitors imbalances, misalignments, bearing wear, and other indicators of impending mechanical problems.

Temperature

Detects overheating, potential component failures, and lubrication issues.

Acoustic

Identifies unusual sounds or emissions that might signal underlying problems.

Current and Voltage: Measures electrical health, pinpointing anomalies that could lead to equipment degradation.

Pressure

Monitors fluid or air systems for leaks, blockages, or changes in operating pressure.

This real-time sensor data is transmitted to cloud servers or edge computing devices, where powerful machine learning algorithms come into play.

Harnessing the Power of Machine Learning in PdM

Machine learning plays a crucial role in PdM, transforming raw sensor data into actionable insights.

Here’s how ML is employed:

Anomaly Detection

ML models are trained on historical data to establish a baseline of “normal” equipment behavior. The models can then detect deviations or anomalies that might indicate an emerging problem.

Fault Diagnosis

Through pattern recognition, ML algorithms can classify different types of faults, helping to pinpoint the root cause of potential issues.

Remaining Useful Life (RUL) Prediction

Advanced ML models can estimate the remaining time before an asset is likely to fail, enabling proactive maintenance planning.

Prescriptive Maintenance

ML can go beyond prediction, suggesting optimal maintenance actions, such as specific repairs or adjustments, based on the detected issue.

Common Machine Learning Algorithms Used in PdM

Supervised Learning

Algorithms like Support Vector Machines (SVM), Decision Trees, and Random Forests are trained on labeled data (both normal and faulty) to classify faults and predict failures.

Unsupervised Learning

Algorithms like K-means Clustering and Principal Component Analysis (PCA) uncover patterns and anomalies in unlabeled data, aiding in early fault detection.

Deep Learning

Neural networks like Convolutional Neural Networks (CNNs) and Recurrent Neural Networks (RNNs) excel at processing time-series sensor data and complex pattern recognition, offering highly accurate predictions.

Implementing an IoT and ML-powered PdM System

Sensor Selection

Determine the most relevant sensors based on the asset type, potential failure modes, and data analysis needs.

Data Collection and Preprocessing

Establish a robust IoT infrastructure and data pipeline ensuring reliable data transmission, cleansing, and formatting.

Feature Engineering

Identify and extract the most informative features from sensor data that best correlate with asset health.

Model Development and Training

Select appropriate ML algorithms, train models on historical data, and perform hyperparameter tuning.

Real-Time Monitoring and Prediction

Deploy models to analyze live sensor data and generate alerts for potential issues.

Maintenance Decision-Making

Integrate PdM insights with maintenance scheduling systems and CMMS (Computerized Maintenance Management Systems).

Continuous Feedback Loop

Regularly evaluate model performance, refine models and retrain them as needed.

Conclusion

Amazing power and accessibility of cloud services both in IoT and Processing power, revolutionized the way we can do our equipment maintenance and sooner or later the industry shows up a new facelift with these power tools.