In modern pcb design and electronic manufacturing, building a high-performance printed circuit board is just the first stage in developing a finished product. Once the PCB is assembled and tested, it must be integrated with other mechanical, electrical, and software components to create a fully functional unit ready for end users. This process is known as box-build assembly, a critical step that transforms a working PCB into a complete electronic system housed within an enclosure, with cables, connectors, power supplies, and firmware all installed and validated.

Box-build assembly is where electronics meet mechanics. It requires precision, planning, and close coordination between design, manufacturing, and testing teams. Whether the end product is an IoT controller, an automotive module, or a medical device, mastering box-build techniques ensures that all subsystems operate in harmony, meeting both performance and safety standards.

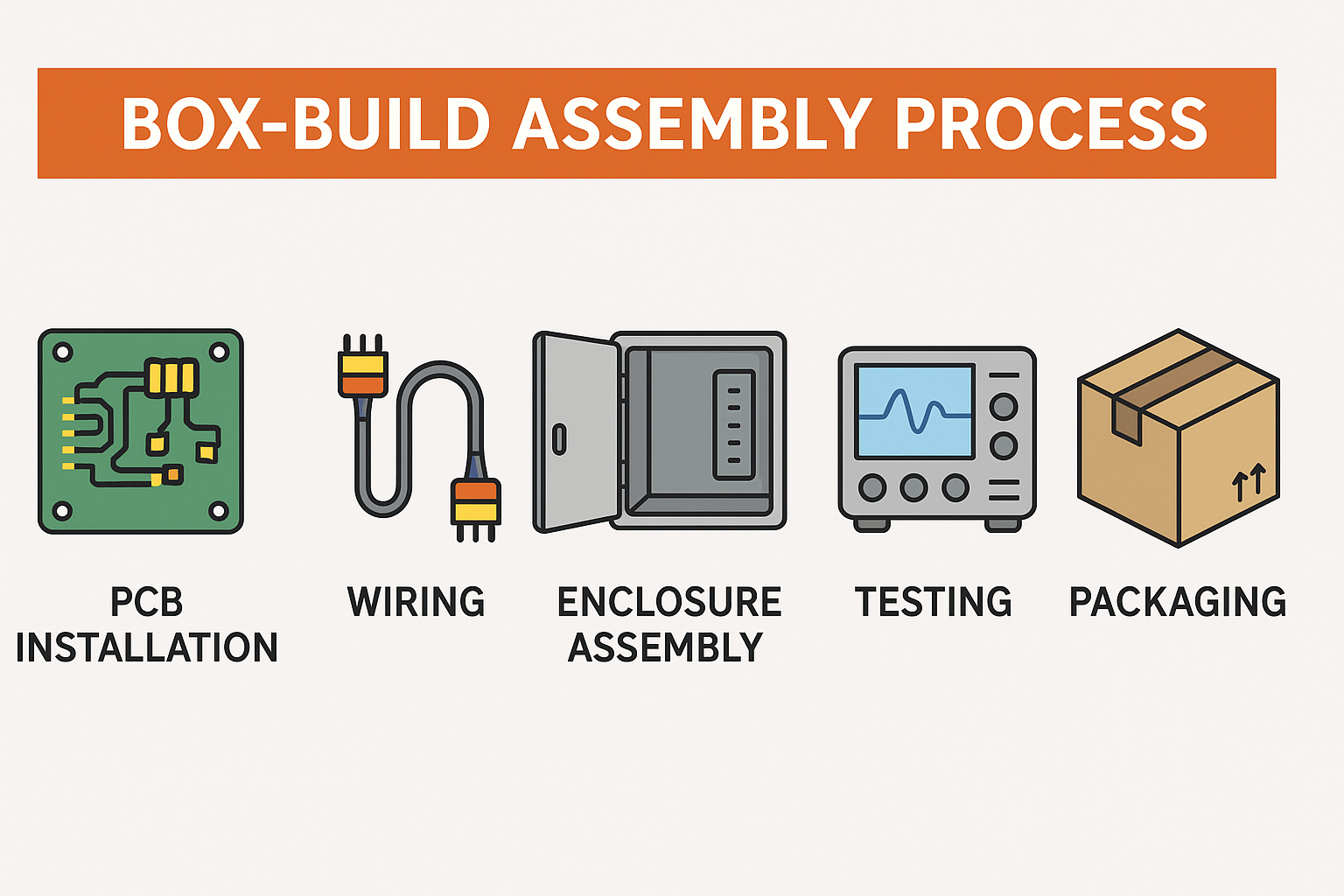

Box-Build Assembly Process

The box-build assembly process integrates multiple elements—PCB assemblies, cables, enclosures, power components, and firmware—into one complete device. Each step demands accuracy and documentation to maintain product quality and compliance.

- Component Preparation: Before assembly begins, all components—PCBs, connectors, screws, wiring harnesses, and enclosures—are inspected and prepared according to the Bill of Materials (BOM). Quality checks at this stage prevent downstream errors.

- PCB Mounting: The printed circuit boards are mounted inside the enclosure or chassis using standoffs or brackets. Proper alignment ensures the board fits mechanically and electrically with the rest of the system.

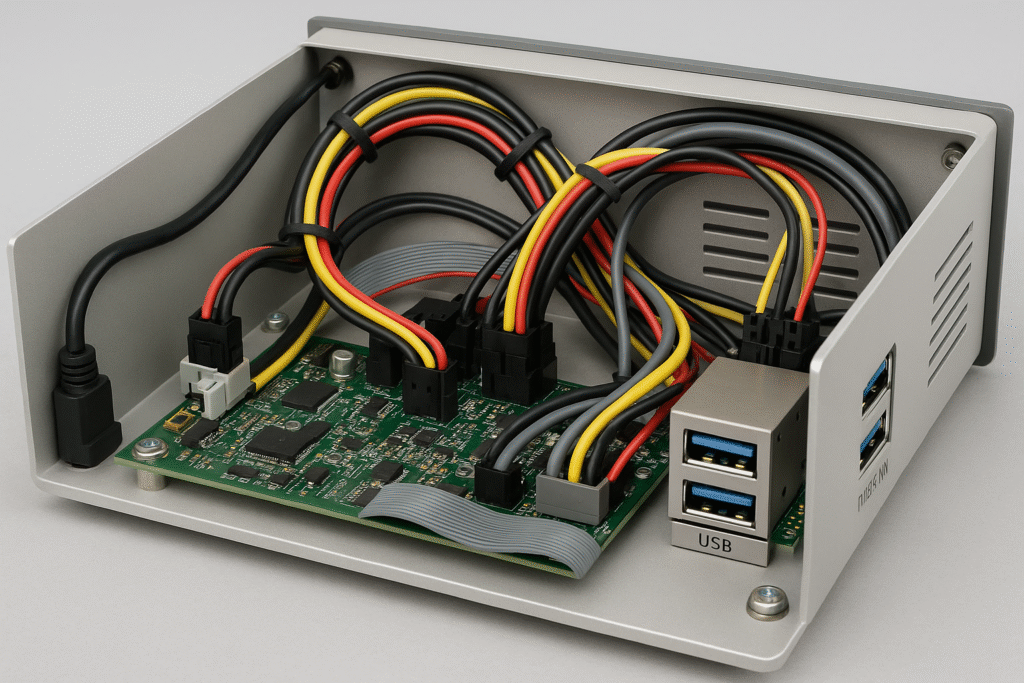

- Cable and Harness Installation: Internal wiring, ribbon cables, and connectors are added to establish communication and power distribution between subsystems. Engineers use design drawings or 3D models to maintain consistent routing and minimize signal interference.

- Integration of Subsystems: Displays, switches, sensors, fans, or external interface ports are connected. Each component is checked for alignment, insulation, and polarity.

- Firmware Loading and Configuration: The microcontrollers or processors are programmed with the required firmware. Configuration steps such as calibration, diagnostics, or ID assignment may follow.

- Testing and Verification: The assembled unit undergoes electrical, mechanical, and functional tests to verify performance and safety. Tests often include insulation resistance, continuity, and full system functionality.

- Labeling and Packaging: Once the device passes all checks, it is labeled with identification data such as serial numbers and safety certifications, then packaged for shipment.

A structured box-build process reduces production time, avoids costly rework, and maintains traceability—essential in regulated industries such as medical and automotive manufacturing.

Box Build vs PCB Assembly

It’s easy to confuse box-build assembly with PCB assembly, but they represent different stages in the manufacturing chain.

PCB assembly (PCBA) focuses on populating electronic components onto the circuit board using surface-mount (SMT) or through-hole technology. The outcome is a functional electronic board that performs a specific electrical function.

Box-build assembly, on the other hand, goes beyond the circuit board. It integrates multiple PCBAs, wiring, enclosures, user interfaces, and software to create a ready-to-use product.

For instance, consider a smart sensor system:

- PCB assembly produces the sensing module and communication interface boards.

- Box-build assembly brings everything together—mounting boards into a sealed enclosure, connecting cables, loading software, and adding power management circuits—resulting in a fully functional, deployable product.

Box-build represents the transition from component-level production to system-level manufacturing. It requires both electrical and mechanical expertise, as well as a deep understanding of ergonomics, thermal management, and compliance requirements.

How Box Build Works

The box-build process starts with engineering design files, often including schematics, 3D mechanical CAD drawings, and wiring diagrams. Manufacturers translate these files into actionable instructions for technicians and assemblers.

- Engineering Review: The design data is reviewed to identify potential mechanical or thermal conflicts. Fit and function tests are simulated before physical assembly.

- Procurement and Inventory Control: Materials are sourced based on the BOM. For large-scale production, manufacturers use MRP (Material Requirements Planning) systems to track inventory and lead times.

- Sub-Assembly Preparation: Smaller modules—like display units or power supply boards—are preassembled and tested independently before being installed into the main housing.

- Final System Assembly: The submodules are integrated into the enclosure. Wiring harnesses and connectors are attached, and fasteners are torqued to specification.

- Verification and Testing: Each stage includes inspection and functional tests to verify proper connections, alignment, and performance.

In modern facilities, digital manufacturing systems track each step, linking serial numbers to specific operators and test results. This traceability provides accountability and allows rapid diagnostics if a product fails later in the field.

Box-Build Enclosure Design

The enclosure plays a critical role in both protecting the electronics and influencing the product’s usability and aesthetics. Box-build enclosure design must balance mechanical strength, heat dissipation, safety, and accessibility for maintenance.

Key design factors include:

- Material Selection: Common materials include aluminum, steel, ABS plastic, and polycarbonate. Metal enclosures provide EMI shielding and durability, while plastics allow lighter and more cost-effective designs.

- Thermal Management: Designers use vents, fans, and heat sinks to manage thermal loads. Simulation tools like CFD (Computational Fluid Dynamics) help visualize airflow and optimize heat dissipation.

- Ingress Protection: Products used in outdoor or industrial environments must meet IP ratings for dust and moisture resistance. Gaskets and seals are used to protect internal electronics.

- Mounting and Ergonomics: The enclosure must accommodate mounting points for PCBs, displays, and connectors while maintaining easy access for service and assembly.

- Compliance and Safety: Designs must meet standards such as UL, CE, and FCC, ensuring safe operation and electromagnetic compatibility.

Mechanical and electrical teams must collaborate closely during the design phase to align PCB placement, cable routing, and mechanical tolerances. Poor coordination can lead to fit issues or EMI problems during testing.

Cable and Harness Integration

Cables and harnesses are vital to the performance and reliability of any electronic system. In box-build assembly, harness integration connects the internal modules and external interfaces efficiently while maintaining signal integrity and safety.

Steps in cable and harness integration:

- Design and Planning: Engineers create detailed cable drawings defining wire gauge, length, color codes, and connector types.

- Fabrication: Wires are cut, stripped, crimped, and labeled according to specifications.

- Routing: Inside the enclosure, cables are routed along defined paths to prevent cross-talk, EMI, and mechanical stress.

- Bundling and Securing: Cable ties, clamps, and heat-shrink tubing are used to secure bundles neatly.

- Testing: Continuity and insulation resistance tests confirm that cables meet electrical requirements before integration.

High-quality harness design minimizes electromagnetic noise and mechanical fatigue, particularly in devices subjected to vibration or temperature variation. Using pre-terminated harnesses also reduces assembly time and human error.

Box-Build Manufacturing Companies

Specialized box-build manufacturing companies provide complete end-to-end solutions, taking products from prototype to full-scale production. These firms combine electronic assembly with mechanical, software, and logistics expertise to deliver turnkey systems.

Capabilities typically include:

- Design and Prototyping: Early-stage design reviews to improve manufacturability and reduce costs.

- Material Procurement: Coordinating suppliers to maintain component availability and consistency.

- Precision Assembly: Utilizing automated tools and ESD-safe workstations to handle sensitive electronics.

- Testing and Validation: Performing in-circuit testing, burn-in, environmental, and functional verification.

- Packaging and Logistics: Final packaging, serialization, and shipping to global customers.

Choosing the right manufacturing partner depends on technical capability, certifications, and production capacity. Leading firms, such as Arshon Technology, offer integrated services for industrial controls, medical electronics, IoT systems, and aerospace components. They maintain ISO 9001 and ISO 13485 certifications, demonstrating adherence to quality and traceability standards.

Testing in Box-Build Assembly

Testing is essential to verify that the fully assembled product functions as designed. Common tests include:

- Functional Testing: Validates that every component performs according to specifications.

- Environmental Testing: Simulates humidity, vibration, and temperature variations.

- Burn-In Testing: Runs devices for extended periods under load to detect early-life failures.

- Safety and Compliance Testing: Confirms compliance with electrical and mechanical safety standards.

Testing not only guarantees quality but also provides valuable data for continuous improvement in design and manufacturing.

Benefits of Box-Build Assembly

- Shorter Production Cycles: Consolidates multiple processes into one streamlined operation.

- Reduced Costs: Minimizes handling, logistics, and assembly errors.

- Quality Assurance: Centralized testing ensures consistent product performance.

- Scalability: Can easily adapt from low-volume prototypes to mass production.

- Traceability: Each unit’s production history can be tracked through serial number databases.

The efficiency of box-build assembly makes it the preferred choice for companies seeking to outsource product integration while maintaining quality and control.

The Future of Box-Build Assembly

Advances in automation, robotics, and AI are transforming box-build manufacturing. Collaborative robots can perform repetitive assembly tasks such as screw fastening and wire routing. Real-time data analytics allows predictive maintenance, improving yield and uptime.

Emerging technologies like 3D printing are also influencing enclosure design and prototyping, reducing lead times for custom parts. As electronic systems become smaller and more integrated, the box-build process will require even tighter collaboration between electrical, mechanical, and software teams.

Conclusion

Box-build assembly for electronic systems represents the convergence of multiple engineering disciplines—electronics, mechanics, and software—into one cohesive production process. It transforms functional PCBs into robust, market-ready devices that meet demanding performance, safety, and compliance requirements. From precise pcb design to enclosure fabrication, cable integration, and testing, each step plays a vital role in the reliability of the final product.

Whether for industrial automation, IoT, or medical devices, box-build assembly remains the key to achieving faster time-to-market and superior quality control. Manufacturers who invest in efficient integration processes position themselves at the forefront of innovation and customer satisfaction.