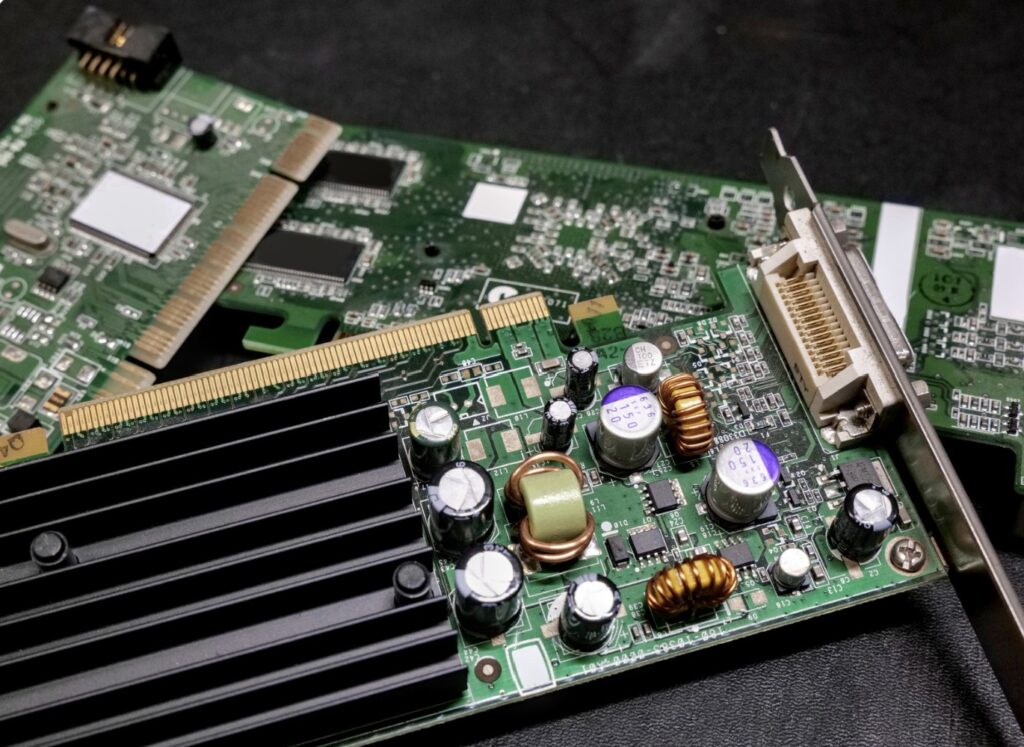

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the structural and electrical framework for components to function. Among the various design considerations for PCBs, thickness is a critical factor that directly impacts circuit performance, reliability, and manufacturability. This article explores the concept of PCB thickness, its influence on circuit performance, and the considerations that designers and manufacturers must take into account in PCB design.

Understanding PCB Thickness

PCB thickness refers to the total thickness of the board, which includes the substrate, copper layers, solder mask, and other finishes. Standard PCB thickness typically ranges from 0.6mm (24 mils) to 2.4mm (94 mils), with 1.6mm (63 mils) being the most commonly used. However, thickness can vary significantly depending on the application and design requirements, such as flexibility, space constraints, and mechanical durability.

Components of PCB Thickness

The overall thickness of a PCB is determined by several components:

- Substrate Material: The substrate, often made of FR4 (a fiberglass-reinforced epoxy laminate), is the primary determinant of board thickness. Other materials like polyimide or metal cores may be used in specialized designs.

- Copper Layers: The thickness of the copper layers, typically measured in ounces per square foot (e.g., 1 oz or 2 oz), adds to the total PCB thickness. Copper thickness impacts current-carrying capacity and thermal performance.

- Prepreg and Core Layers: Multilayer PCBs consist of prepreg (pre-impregnated resin) and core layers that insulate and bond the copper layers together.

- Surface Finishes and Solder Mask: These add minor contributions to thickness but are crucial for protecting the board and improving solderability.

How PCB Thickness Affects Circuit Performance

The thickness of a PCB influences several critical aspects of circuit performance, including signal integrity, thermal management, and mechanical strength. Let’s examine these effects in detail:

1. Signal Integrity

PCB thickness plays a significant role in signal integrity, particularly in high-frequency and high-speed circuits. The thickness of the substrate impacts:

- Impedance Control: Maintaining consistent impedance is critical for high-speed signal transmission. Thicker boards require careful adjustments to trace width and spacing to achieve the desired impedance.

- Signal Propagation Delay: Signal speed is influenced by the dielectric constant (Dk) of the substrate material and its thickness. Thicker PCBs can introduce slight delays in signal propagation, which must be accounted for in timing-critical designs.

- Crosstalk and Noise: Increasing the separation between signal layers in thicker PCBs can reduce crosstalk and electromagnetic interference (EMI), improving overall signal integrity.

2. Thermal Performance

PCB thickness impacts the board’s ability to dissipate heat, which is essential for maintaining component performance and longevity.

- Thinner PCBs: Thinner boards may struggle with thermal dissipation, especially in power-intensive applications, leading to overheating and reduced reliability.

- Thicker PCBs: Increased thickness allows for better heat distribution and can accommodate thicker copper layers, which enhance thermal conductivity. This is particularly beneficial in applications like power electronics and LED lighting.

3. Mechanical Strength and Durability

The mechanical properties of a PCB are directly tied to its thickness.

- Thin PCBs: These are flexible and lightweight, making them suitable for compact devices and wearable electronics. However, they are more prone to warping and mechanical damage.

- Thick PCBs: Thicker boards offer greater structural integrity and are ideal for applications requiring mechanical robustness, such as automotive and industrial systems.

4. Space Constraints

In miniaturized designs, thinner PCBs are preferred to conserve space and reduce weight. However, these boards require advanced manufacturing techniques to maintain functionality and reliability.

Choosing the Right PCB Thickness for Your Design

Selecting the appropriate PCB thickness involves balancing performance, cost, and application-specific requirements. Key factors to consider include:

- Application Requirements: High-power applications benefit from thicker boards for better thermal management. Portable and wearable devices require thinner boards for flexibility and compactness.

- Layer Count: Multilayer PCBs inherently have greater thickness due to the additional copper and insulation layers. Designers must ensure that the final thickness aligns with enclosure and connector specifications.

- Impedance Control: For high-frequency circuits, the thickness must support the trace dimensions needed for controlled impedance.

- Cost Considerations: Thicker boards typically require more materials and may increase manufacturing costs. Conversely, thinner boards may need advanced fabrication techniques, which also raise expenses.

- Manufacturing Tolerances: Manufacturers have specific tolerances for PCB thickness, which must be communicated during the design phase to avoid production issues.

Standard vs. Custom PCB Thickness

While standard PCB thicknesses (e.g., 1.6mm) cater to most general applications, custom thicknesses are often required for specialized designs.

- Thin PCBs: Used in flexible circuits, smartphones, and medical devices where compactness is critical.

- Thick PCBs: Preferred for heavy-duty applications like military, automotive, and industrial equipment, where mechanical durability and high current-carrying capacity are crucial.

PCB Thickness in Specific Applications

1. Consumer Electronics

Thin PCBs are widely used in smartphones, tablets, and laptops to enable lightweight and compact designs.

2. Automotive and Aerospace

Thick PCBs are essential for handling high-power circuits, harsh environmental conditions, and mechanical stresses.

3. Medical Devices

PCB thickness must balance compactness and durability in life-critical devices like pacemakers and diagnostic equipment.

4. Industrial Automation

PCBs in industrial equipment are often thick to withstand vibrations, thermal cycling, and heavy loads.

Emerging Trends in PCB Thickness

- Flexible and Rigid-Flex PCBs: Flexible PCBs often feature ultra-thin substrates, enabling new possibilities in wearable technology and IoT devices.

- Advanced Materials: High-frequency materials with tailored thicknesses are being developed for applications like 5G networks and radar systems.

- Hybrid PCBs: These combine layers of varying thicknesses to meet specific mechanical and electrical requirements within the same board.

- Environmentally Friendly Designs: Thinner PCBs with optimized material use are gaining traction for their reduced environmental impact.

Conclusion

PCB thickness is a fundamental aspect of circuit design that significantly influences performance, durability, and manufacturability. Whether optimizing signal integrity in high-speed applications, enhancing thermal management in power systems, or ensuring mechanical robustness for industrial use, the right PCB thickness is critical to achieving design success.

Understanding how PCB thickness interacts with other design parameters allows engineers to create optimized solutions that meet application-specific requirements. As technology advances, innovations in materials, fabrication techniques, and design tools will further expand the possibilities for leveraging PCB thickness to enhance circuit performance.