In the electronics industry, maintaining product reliability after production is as important as precision during assembly. From pcb design to final inspection, every stage of manufacturing contributes to long-term device performance. However, even the most sophisticated designs can experience variations during production that require verification and improvement. Post-Manufacturing Testing and Improvement processes bridge this gap by validating function, durability, and consistency while identifying opportunities for continuous enhancement.

Post-Manufacturing Quality Testing

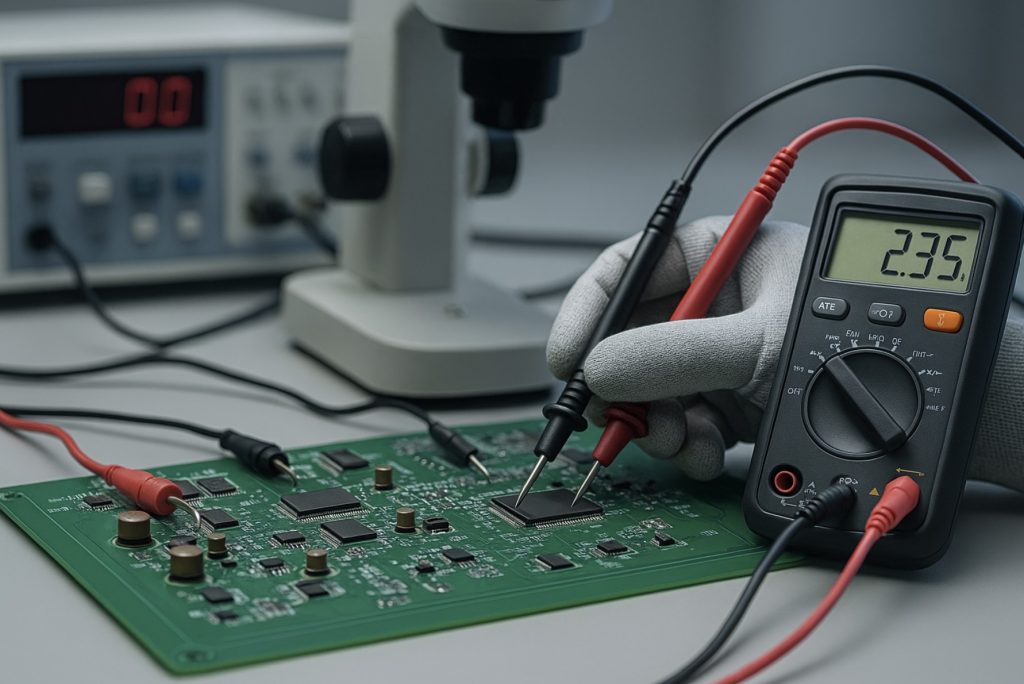

Post-manufacturing quality testing is a critical phase in the production lifecycle, designed to validate that finished products meet all specifications before release. It confirms the integrity of assembly, solder quality, component placement, and electrical performance. For electronics manufacturers, this phase not only verifies compliance with customer and regulatory standards but also prevents field failures that could damage brand reputation.

Common post-manufacturing tests include visual inspection, in-circuit testing (ICT), automated optical inspection (AOI), and X-ray analysis. These tests detect solder defects, short circuits, misaligned components, and internal structural flaws. Automated systems improve accuracy and allow rapid testing across large production volumes. For high-reliability industries such as aerospace, automotive, and medical, 100% inspection of all assemblies is standard practice.

In addition, functional test stations simulate real-world operating conditions. Boards are powered up, communication protocols are verified, and sensors or actuators are tested to confirm performance consistency. Any deviation from expected results triggers corrective action, feeding valuable data back to engineering teams for process improvement.

Electronics Rework Services

Despite the precision of modern SMT and through-hole processes, occasional defects or performance issues are inevitable. Electronics rework services play a vital role in salvaging and improving products that do not initially pass quality checks. Rework technicians are trained to repair solder joints, replace defective components, or modify traces without damaging the surrounding circuitry.

Advanced rework equipment includes hot air and infrared rework stations capable of precise thermal control. This allows removal and replacement of fine-pitch ICs or BGAs without overheating neighboring parts. For multilayer PCBs, technicians follow strict thermal profiles to prevent delamination or internal via damage.

In addition to physical repairs, firmware updates or parameter calibrations may also be part of rework. In some cases, design revisions identified through testing are implemented directly into later production runs. By offering rework instead of scrapping, manufacturers save significant costs and reduce waste while improving yield and sustainability.

Product Improvement After Assembly

Once assembly and testing are complete, engineers often identify ways to improve product reliability, functionality, or manufacturability. Product improvement after assembly focuses on fine-tuning designs and production processes based on data collected during testing and field use.

Engineers review test results to identify recurring issues such as marginal signal integrity, mechanical stress failures, or component tolerance variations. These findings lead to design enhancements—such as improving grounding schemes, adding thermal relief features, or selecting more robust materials.

For instance, in pcb design, revising trace widths or spacing can reduce signal noise and improve EMI performance. Similarly, updating component footprints to match more stable supply chains can enhance long-term manufacturability. Product improvement is a continuous feedback loop, where lessons learned from each production batch inform the next design iteration.

This process not only strengthens reliability but also helps companies maintain competitiveness by incorporating incremental innovations without full redesign cycles.

Burn-In Testing Services

Burn-in testing is a powerful reliability screening technique used to identify early-life failures and confirm product endurance under stress. The process involves operating devices at elevated temperatures, voltages, or workloads for an extended period to simulate accelerated aging.

Burn-in testing services are particularly valuable for high-reliability electronics such as aerospace controls, medical instrumentation, and automotive safety systems. These devices must perform flawlessly over long operational lifetimes, making early detection of weak components critical.

During a burn-in cycle, test fixtures continuously monitor current, voltage, and performance metrics. Any device that deviates from nominal parameters is flagged for analysis. By filtering out weak units before shipment, manufacturers significantly reduce field failures and warranty claims.

Modern burn-in systems are equipped with automated data logging and real-time analytics. This allows engineers to track performance trends across thousands of units, identifying patterns that point to potential design or process weaknesses.

Stress Testing PCBs

Printed circuit boards endure mechanical, thermal, and electrical stress during operation. Stress testing evaluates their ability to withstand these conditions without degradation. The process may involve temperature cycling, humidity exposure, vibration testing, and power cycling.

Thermal cycling exposes PCBs to repeated hot and cold extremes to evaluate solder joint reliability and material expansion properties. Vibration testing simulates mechanical shocks experienced in vehicles, industrial machinery, or aerospace applications. High-power PCBs also undergo electrical overstress testing to verify current-carrying capacity and dielectric strength.

For boards used in harsh environments, conformal coating adhesion and corrosion resistance tests are also performed. Engineers record detailed failure modes—such as cracked solder joints, delamination, or intermittent connections—and use these insights to enhance layout design or material selection.

Stress testing PCBs is a proactive way to confirm that the design can survive not just laboratory conditions but real-world scenarios, extending product life and reliability.

Functional Verification Post Assembly

Functional verification after assembly validates that the entire product performs exactly as intended under operational conditions. Unlike in-circuit testing that checks components individually, functional verification examines the system as a whole.

In this stage, test engineers power up the device, load firmware, and connect it to external peripherals or communication networks. Input and output signals are measured to confirm accuracy, timing, and stability. Automated test equipment (ATE) is often used to execute hundreds of test cases quickly, ensuring consistent results across production batches.

Functional verification also includes calibration steps where sensors, displays, or analog circuits are fine-tuned to meet specifications. In communication devices, this may involve verifying wireless signal strength or data transmission integrity.

The results from functional verification not only confirm quality but also identify potential long-term reliability issues. Early detection allows targeted rework or design improvement, avoiding costly field failures later.

Failure Analysis and Redesign

When failures occur during post-manufacturing tests or in the field, failure analysis and redesign processes come into play. Engineers investigate the root cause using a combination of electrical, mechanical, and chemical analysis techniques.

Common methods include optical microscopy, X-ray inspection, scanning electron microscopy (SEM), and cross-sectioning. Electrical testing can reveal open circuits or leakage paths, while chemical residue analysis can detect contamination or flux residues that affect performance.

Once the failure mechanism is identified, engineers redesign affected circuits or materials to prevent recurrence. For example, they might modify thermal relief patterns to prevent solder cracking, or change component suppliers to eliminate batch variability.

Failure analysis not only restores product functionality but also contributes to a stronger design database. Over time, accumulated knowledge from multiple analyses creates a foundation for predictive reliability engineering—reducing future defect rates and accelerating product development cycles.

Reliability Testing Services

Reliability testing goes beyond verifying that a product works—it evaluates how long it will continue to work under varying conditions. Reliability testing services use statistical methods and accelerated aging tests to predict product lifespan and identify potential weaknesses before they occur.

Typical reliability tests include high-temperature operating life (HTOL), temperature-humidity bias (THB), and mechanical shock or vibration tests. Each test aims to replicate years of operation within a shorter time frame. Engineers analyze data to calculate mean time to failure (MTTF) or failure rate distributions, giving valuable insight into expected product longevity.

For products with safety or medical applications, reliability data is required for regulatory approval. ISO 9001 and ISO 13485-certified manufacturers often integrate these tests into their standard quality assurance plans.

Reliability testing also extends to components such as capacitors, connectors, and solder joints. Advanced techniques like finite element modeling (FEM) and real-time monitoring help predict where failures are most likely to occur, guiding design refinements.

Continuous Improvement in Manufacturing

Continuous improvement in manufacturing is the philosophy of making small, systematic enhancements to processes and products over time. Rooted in lean and Six Sigma methodologies, it focuses on eliminating waste, reducing variation, and increasing efficiency.

Post-manufacturing data plays a key role in this effort. Test results, rework statistics, and field failure data feed into quality management systems that identify recurring patterns. Once patterns are found, cross-functional teams implement corrective and preventive actions (CAPA).

For example, if solder joint defects are repeatedly detected during inspection, engineers may adjust stencil design, reflow profiles, or flux chemistry. If failures are traced back to component suppliers, quality teams collaborate to tighten incoming inspection criteria or qualify alternative vendors.

Continuous improvement also relies on employee feedback. Production technicians often notice subtle process variations before they appear in test data. Encouraging open communication between engineering, production, and quality departments ensures that every issue becomes an opportunity for refinement.

This mindset transforms post-manufacturing testing from a reactive activity into a proactive driver of innovation and efficiency.

Product Validation After Production

Even after final testing and release, product validation continues through pilot runs, reliability trials, and field evaluations. This step verifies that devices perform consistently in real-world conditions and that production processes remain stable over time.

Product validation after production often involves environmental testing, user trials, and statistical sampling. Field validation provides feedback on usability, software behavior, and long-term stability under varied environmental factors. Data from these trials is analyzed to identify improvement opportunities for both product and process.

Validation teams also confirm compliance with customer-specific requirements and industry standards. For regulated sectors such as medical or automotive, validation documentation is mandatory for audits and certification renewals.

By closing the loop between production and end-use performance, manufacturers achieve continuous alignment between design intent, manufacturing execution, and customer satisfaction.

Integration with Quality Management Systems

To maximize effectiveness, all post-manufacturing testing and improvement activities should be integrated within a formal Quality Management System (QMS). This system provides the structure to record test results, track nonconformities, and implement corrective actions in a controlled and traceable way.

Standards such as ISO 9001 and ISO 13485 require documented evidence of testing and verification processes. Using digital QMS platforms, manufacturers can automatically capture data from test stations, link it to specific serial numbers, and generate analytics dashboards.

Integration enables quick decision-making based on accurate real-time data. It also facilitates audit readiness, as all documentation—from inspection results to corrective action reports—is readily available.

Data Analytics in Post-Manufacturing Testing

With the rise of Industry 4.0, data analytics has become an essential component of post-manufacturing improvement. Test systems, sensors, and inspection machines now generate massive amounts of data that can reveal process inefficiencies or hidden failure trends.

By applying machine learning algorithms, manufacturers can predict failure modes before they occur. Statistical process control (SPC) charts identify when processes drift outside acceptable limits, triggering automatic alerts for corrective action.

This predictive approach reduces downtime, enhances first-pass yield, and strengthens process stability. It also supports closed-loop feedback between design and manufacturing, leading to faster innovation cycles and higher overall product reliability.

Sustainability Through Post-Manufacturing Improvement

In addition to quality and reliability benefits, post-manufacturing improvement contributes to sustainability. Rework and repair reduce electronic waste, while reliability testing extends product lifespans and minimizes returns.

Manufacturers committed to green initiatives integrate energy efficiency and recyclability considerations into their testing and improvement cycles. By doing so, they not only meet environmental regulations but also strengthen their brand reputation as responsible producers.

Sustainable improvement is no longer an optional add-on—it is an essential part of modern manufacturing excellence.

Conclusion

Post-Manufacturing Testing and Improvement is the foundation of long-term product success. It validates quality, enhances performance, and drives continuous innovation through real-world data. From pcb design to functional verification and failure analysis, each phase provides insights that strengthen future designs and processes.

Manufacturers that invest in systematic testing, rework, and feedback achieve superior reliability, lower warranty costs, and stronger customer trust. As technology advances and production volumes grow, integrating advanced analytics, automation, and sustainability into post-manufacturing practices will define the next generation of global manufacturing excellence.