The rise of wearable technology has reshaped consumer electronics, medical devices, and industrial monitoring systems. From smartwatches to fitness trackers, from wearable ECG monitors to industrial safety gear, all share one challenge—power management in wearable electronics. Managing power efficiently is the foundation of usability, comfort, and functionality. Since most wearables are compact, battery capacity is limited, which means engineers must design circuits, optimize firmware, and innovate around pcb design to achieve the best energy efficiency. This article examines techniques, technologies, and future directions for managing power in wearables.

Why Power Management Matters in Wearables

Unlike smartphones or laptops, wearable devices cannot carry large batteries. Weight, size, and user comfort are critical factors. A smartwatch that needs charging every few hours or a health monitor that stops working during sleep monitoring loses consumer trust. Effective power management ensures:

- Extended battery life without frequent charging.

- Consistent performance of sensors and wireless communication.

- Safe operation, especially in medical devices where uninterrupted monitoring is required.

- Smaller and lighter form factors that users actually want to wear.

Challenges in Power Management

- Limited battery capacity: Compact form factors restrict battery size.

- Continuous sensing: Many wearables must constantly monitor data such as heart rate, oxygen saturation, or motion.

- Wireless connectivity: Bluetooth, Wi-Fi, or LTE modules consume significant power when active.

- Thermal constraints: Efficient power management reduces unwanted heat, improving comfort and safety.

- Data processing requirements: Advanced features like AI-driven health insights increase processing loads.

To overcome these challenges, engineers must consider every layer of system design—from PCB layout to firmware optimization.

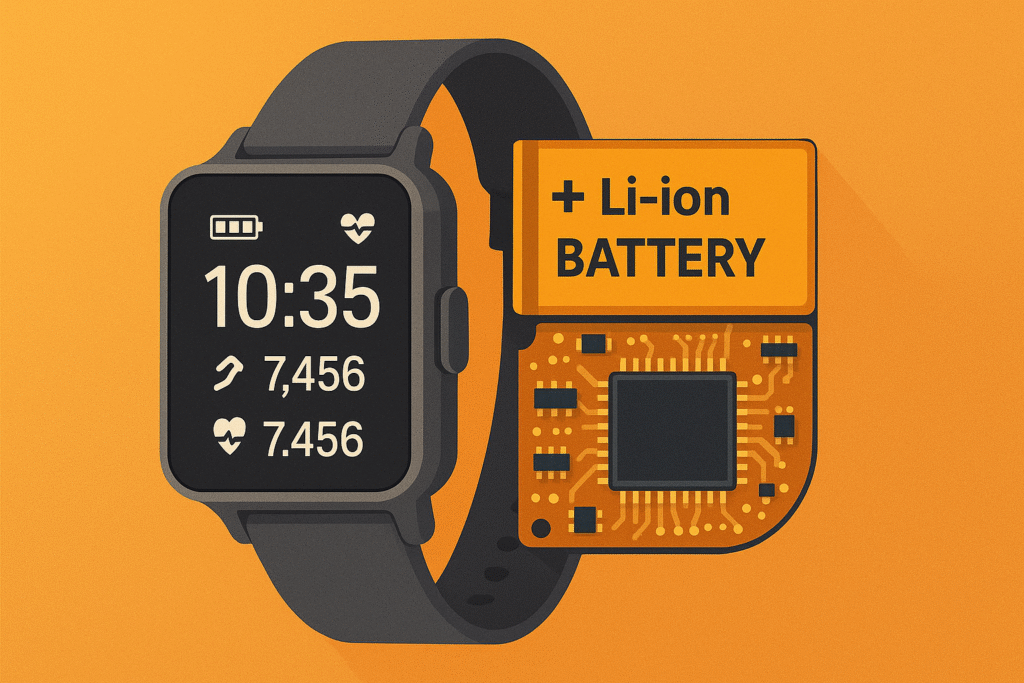

Power Sources for Wearable Electronics

The choice of power source is fundamental. Common options include:

- Lithium-ion and lithium-polymer batteries: The standard choice for most wearables, offering high energy density and rechargeable cycles.

- Solid-state batteries: A developing technology offering enhanced safety and smaller footprints.

- Coin cell batteries: Used in ultra-low-power wearables like medical patches or simple fitness trackers.

- Energy harvesting: Future wearables may integrate solar cells, kinetic energy systems, or body-heat thermoelectric generators to supplement or replace batteries.

Each source has trade-offs in terms of rechargeability, weight, size, and lifespan.

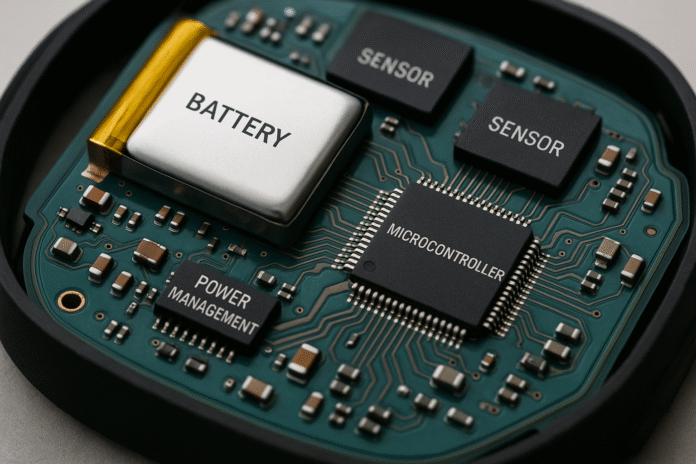

PCB Design and Power Management

PCB design plays a central role in power management strategies. Key considerations include:

- Component placement: Power-hungry components like wireless chips must be isolated and routed with minimal losses.

- Power planes and grounding: Proper power distribution reduces resistance losses.

- Low-dropout regulators (LDOs) and DC-DC converters: Choosing the right regulators impacts efficiency.

- Multi-layer PCB design: Enables better signal integrity and efficient routing for power delivery.

- Thermal management: Efficient heat dissipation improves battery performance and device comfort.

A well-optimized PCB design can save milliwatts per cycle, which translates into hours or even days of additional operation time.

Techniques for Power Reduction

1. Dynamic Power Scaling

Wearables adjust voltage and clock frequency of processors depending on task requirements. Low-demand processes run at minimal energy levels, while higher demands like GPS tracking trigger higher power states.

2. Sleep Modes and Duty Cycling

Microcontrollers and sensors can enter deep sleep states when not needed. Duty cycling allows devices to operate in bursts, waking intermittently to take readings before sleeping again.

3. Efficient Communication Protocols

Wireless communication is one of the largest power consumers in wearables. Strategies include:

- Using Bluetooth Low Energy (BLE) instead of classic Bluetooth.

- Compressing data locally before transmitting to reduce communication cycles.

- Employing edge processing to minimize continuous cloud connectivity.

4. Energy Harvesting Integration

Solar, kinetic, or thermoelectric harvesters supplement battery capacity. For example, smartwatches with solar-assisted charging extend battery life significantly in outdoor use.

5. Sensor Optimization

Not all sensors need continuous activation. For example, accelerometers can stay active in low-power modes to detect motion, while higher-power GPS modules activate only when needed.

Power Management Integrated Circuits (PMICs)

Modern wearables rely heavily on PMICs to handle multiple power rails efficiently. These ICs:

- Regulate and distribute power between processors, sensors, and wireless chips.

- Manage charging circuits for lithium-ion batteries.

- Provide safety features like over-voltage and short-circuit protection.

- Reduce PCB footprint by integrating multiple regulators into one chip.

PMICs are essential for balancing performance, safety, and energy efficiency.

Wireless Communication and Power Trade-offs

Wireless connectivity significantly influences power budgets. Engineers must balance range, speed, and efficiency:

- Bluetooth Low Energy (BLE): The most common choice in wearables, optimized for low duty cycles.

- NFC: Consumes little power, used for contactless payments and identification.

- Wi-Fi: High power consumption, used sparingly in wearables.

- Cellular (LTE-M, NB-IoT): Used in advanced wearables like medical devices and smartwatches with independent connectivity.

Hybrid strategies often work best. For example, a smartwatch may use BLE for regular syncing but switch to LTE when away from the paired smartphone.

Power Management in Health Wearables

Medical wearables such as glucose monitors, ECG patches, and hearing aids demand highly reliable power management. Key requirements include:

- 24/7 monitoring with minimal downtime.

- Accuracy: Power fluctuations can compromise sensor readings.

- Safety: Overheating or battery swelling is unacceptable in medical use.

Engineers must carefully design PCB power distribution networks, optimize microcontroller sleep cycles, and use efficient data protocols to extend reliability.

Case Study: Smartwatches

Smartwatches illustrate many power management strategies:

- They employ multi-core processors with dynamic power scaling.

- Displays use AMOLED with always-on low-power modes.

- Sensors like accelerometers remain in ultra-low-power states until motion is detected.

- BLE handles constant syncing, while LTE or Wi-Fi activates only when required.

Battery life improvements often result from incremental optimizations across all these layers.

Role of Firmware in Power Management

Hardware optimization is critical, but firmware decisions can make or break efficiency. Firmware contributes by:

- Scheduling tasks to maximize sleep time.

- Managing communication cycles intelligently.

- Calibrating sensors to avoid redundant measurements.

- Supporting OTA updates without excessive power draw.

Efficient firmware allows hardware to spend as much time as possible in low-power states, extending overall lifetime.

Energy Harvesting: The Future of Power Management

While batteries remain central, energy harvesting is gaining traction:

- Solar charging: Useful in smartwatches and fitness trackers with outdoor exposure.

- Piezoelectric and kinetic harvesting: Generate small amounts of energy from user motion.

- Thermoelectric harvesting: Converts body heat into power.

Though currently supplemental, improvements in harvesting technology could enable self-sustaining wearables in the future.

Thermal Management in Wearables

Heat is an overlooked byproduct of power consumption. Wearables must balance efficiency with user comfort:

- Low thermal resistance PCB design helps spread and dissipate heat.

- Power-efficient components reduce hotspots.

- Material choice in wearable enclosures improves comfort during prolonged use.

Excess heat not only reduces user comfort but also affects battery performance and component lifespan.

Testing Power Management in Wearables

Power optimization is incomplete without rigorous testing. Common methods include:

- Battery drain profiling under various workloads.

- Thermal imaging to detect hot spots.

- Communication stress testing to evaluate wireless efficiency.

- Long-duration testing for health wearables to guarantee continuous operation.

Testing allows engineers to identify inefficiencies that simulations alone might not reveal.

Trends in Power Management for Wearable Electronics

The future of wearable power management points toward:

- AI-assisted power scheduling: Machine learning predicts user habits to optimize energy consumption.

- Flexible batteries: Integration into straps or clothing.

- Smaller, more efficient PMICs: Supporting even tinier form factors.

- Hybrid power strategies: Combining batteries with energy harvesting.

As wearable electronics integrate more features, power management innovation will define which products succeed in the market.

Conclusion

Effective power management in wearable electronics requires a multidisciplinary approach—balancing hardware efficiency, optimized pcb design, intelligent firmware, and innovative energy sources. From medical devices to fitness trackers, the key is to maximize energy efficiency without compromising performance, safety, or comfort. As technology advances, the convergence of advanced PMICs, energy harvesting, and AI-driven scheduling will lead to longer-lasting, safer, and smarter wearable devices.