Power is the lifeblood of any embedded system, determining reliability, efficiency, and performance. Whether designing an IoT sensor node, a wearable device, or a high-performance industrial controller, engineers must carefully plan the power architecture. A poorly designed power supply can lead to unstable operation, noise issues, overheating, or even permanent damage to the electronics. That’s why power supply design for embedded systems is one of the most critical aspects of development. From the choice of regulators and converters to filtering, thermal management, and validation, every step affects the final outcome. Strong pcb design plays an equally important role, as routing, ground planes, and component placement determine whether the power system functions reliably in real-world conditions.

In this article, we will cover the essential principles of power supply design for embedded systems, explore design considerations, and highlight best practices that ensure stable and efficient operation.

Understanding Power Requirements

Before selecting components or drawing schematics, it’s vital to assess the system’s power requirements.

- Voltage rails: Modern microcontrollers often require multiple supply rails (e.g., 3.3V logic, 1.2V core).

- Current demand: Peak and average currents differ. For example, RF transceivers consume milliamps during transmission but microamps in sleep mode.

- Load variations: Power must remain stable across different operational states.

- Efficiency targets: Battery-powered devices require energy-efficient supplies.

Power budgeting at the start ensures correct sizing of regulators, capacitors, and thermal solutions.

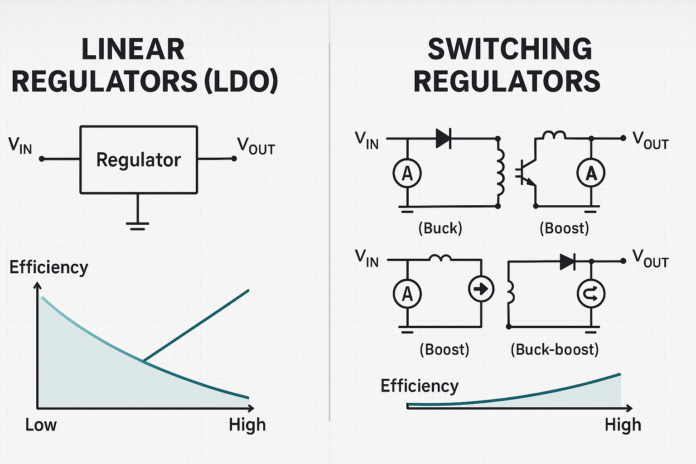

Linear Regulators vs. Switching Regulators

The two most common regulator types have distinct trade-offs.

Linear Regulators (LDOs)

- Advantages: Low noise, simplicity, low cost.

- Disadvantages: Inefficient with high input-to-output voltage difference.

- Use cases: Analog circuits, audio systems, RF devices where noise must be minimized.

Switching Regulators (SMPS)

- Advantages: High efficiency, compact size for high-power loads.

- Disadvantages: Generates EMI, requires careful pcb design with inductors and capacitors.

- Use cases: Battery-powered systems, high-performance microcontrollers, and industrial electronics.

Often, designs use a hybrid approach: a switching regulator to step down from higher input voltages, followed by an LDO for noise-sensitive circuits.

Choosing DC-DC Converter Topologies (Buck, Boost)

Switching regulators employ different topologies depending on the system’s needs.

- Buck converter: Steps down voltage. Common in embedded systems where 5V or 12V must become 3.3V.

- Boost converter: Steps up voltage. Essential for powering devices that need higher rails from batteries.

- Buck-boost: Provides stable output even if input fluctuates above and below the desired voltage.

- SEPIC: Useful for automotive or wide input ranges.

Selecting the correct topology ensures efficiency, stability, and proper functionality across varying conditions.

Selecting Inductors and Capacitors

Inductors and capacitors are at the heart of power circuits.

- Inductors: Must be sized for current handling, saturation levels, and switching frequency. Too small an inductor leads to ripple, while too large increases losses.

- Capacitors: Input capacitors stabilize input rails, while output capacitors smooth voltage ripple. Low-ESR ceramic capacitors are often preferred.

- Bulk capacitance: Helps manage sudden load transients.

The correct selection of passive components is just as important as choosing regulators.

Power Sequencing and Startup

Many embedded devices require rails to power up in a specific order. For example:

- A processor may require its core voltage before I/O voltage.

- FPGAs demand strict sequencing for internal regulators.

- Sensors may need a controlled startup to avoid damage.

Supervisory ICs and sequencing controllers ensure orderly startup and shutdown, protecting devices from undefined states.

Handling Inrush Current and Transients

When a device powers on, large capacitors or inductive loads can draw inrush currents.

- NTC thermistors or current-limiting resistors help manage inrush.

- Soft-start circuits gradually ramp voltage, reducing stress.

- Transient suppressors (TVS diodes) protect against voltage spikes caused by hot plugging or environmental disturbances.

Managing inrush current increases reliability and prevents power system failure.

Power Distribution Networks (PDN)

The PDN delivers power from regulators to all ICs on the board. Inadequate PDN design leads to instability, noise, and failures.

- Wide traces and planes: Reduce resistance and voltage drop.

- Star topology vs. distributed rails: Depends on current demand and system architecture.

- Decoupling capacitors: Must be placed close to IC power pins. Multiple values (e.g., 100nF + 10uF) handle different frequency ranges.

PDN integrity is one of the most critical aspects of pcb design for embedded systems.

Low-Power Design Techniques

Battery-powered devices depend on efficient power supply design.

- Dynamic voltage scaling (DVS): Adjusts supply voltage according to load.

- Sleep modes: Use ultra-low Iq regulators during standby.

- Efficient topologies: Synchronous buck converters minimize switching losses.

- Leakage reduction: Proper component selection reduces quiescent drain.

These methods extend battery life and improve energy efficiency.

EMI Considerations in Power Supply Design

Switching regulators inherently generate electromagnetic interference. Poor design can disrupt nearby circuits or fail compliance testing.

- Proper layout: Minimize loop areas carrying high-frequency currents.

- Ground planes: Reduce EMI coupling paths.

- Shielding and filtering: Ferrite beads and LC filters mitigate conducted noise.

- Spread-spectrum modulation: Some regulators offer frequency modulation to reduce EMI peaks.

Considering EMI from the start avoids costly redesigns and compliance issues.

Thermal Management in Power Circuits

Heat is a common byproduct of power supplies. If not managed, it shortens component lifespan.

- Heat sinks: Essential for high-power regulators and MOSFETs.

- Thermal vias and copper pours: Spread heat efficiently in the PCB.

- Component derating: Using parts below maximum ratings improves reliability.

- Simulation tools: Thermal modeling predicts hotspots before manufacturing.

A strong thermal design prevents overheating and ensures long-term operation.

Testing and Validation

Testing validates the design under real-world conditions.

- Load testing: Ensures regulators handle peak and steady-state currents.

- Ripple and noise measurement: Oscilloscopes check for compliance with IC tolerances.

- Thermal profiling: Identifies hotspots.

- Stress testing: Subjects the design to overvoltage, short-circuit, and temperature extremes.

Only after thorough validation can a power supply design be considered production-ready.

Conclusion

Power supply design for embedded systems is a discipline that blends theoretical knowledge with practical engineering. From understanding power requirements to handling EMI and thermal challenges, every design decision matters. By selecting appropriate regulators, designing efficient PDNs, and validating performance under stress, engineers ensure embedded systems run reliably. Just as strong pcb design supports signal integrity, robust power supply design guarantees energy delivery with efficiency and stability. Adopting best practices not only prevents costly failures but also extends product lifespan, making power system design one of the most important parts of embedded engineering.