In today’s rapidly evolving agricultural landscape, technology plays an essential role in transforming how farmers manage their resources and operate their equipment. Among the most promising advancements is predictive maintenance, a data-driven approach that leverages artificial intelligence (AI) and the Internet of Things (IoT) to ensure the longevity of agricultural machinery and optimize the use of resources. Predictive maintenance is more than just a technological buzzword—it represents a new paradigm for managing equipment, reducing downtime, and improving efficiency in agriculture.

The Challenge of Equipment Maintenance in Agriculture

Agricultural machinery, such as tractors, harvesters, and irrigation systems, are vital to modern farming operations. However, these machines are subject to constant wear and tear due to prolonged use, harsh environmental conditions, and heavy workloads. Traditionally, farmers have relied on reactive or preventive maintenance strategies to keep their equipment running.

Reactive maintenance involves repairing machinery only after a breakdown occurs, which can lead to costly downtime, lost productivity, and expensive repairs. On the other hand, preventive maintenance schedules regular inspections and repairs, regardless of the actual condition of the machinery. While this approach reduces the risk of sudden breakdowns, it can result in unnecessary repairs and costs, as equipment may be serviced when it is not needed.

Neither of these approaches is ideal in today’s highly competitive and resource-conscious agricultural environment. Farmers need a more intelligent solution—one that allows them to predict equipment failures before they happen, avoid unnecessary maintenance, and extend the lifespan of their machinery. This is where predictive maintenance comes into play.

What is Predictive Maintenance?

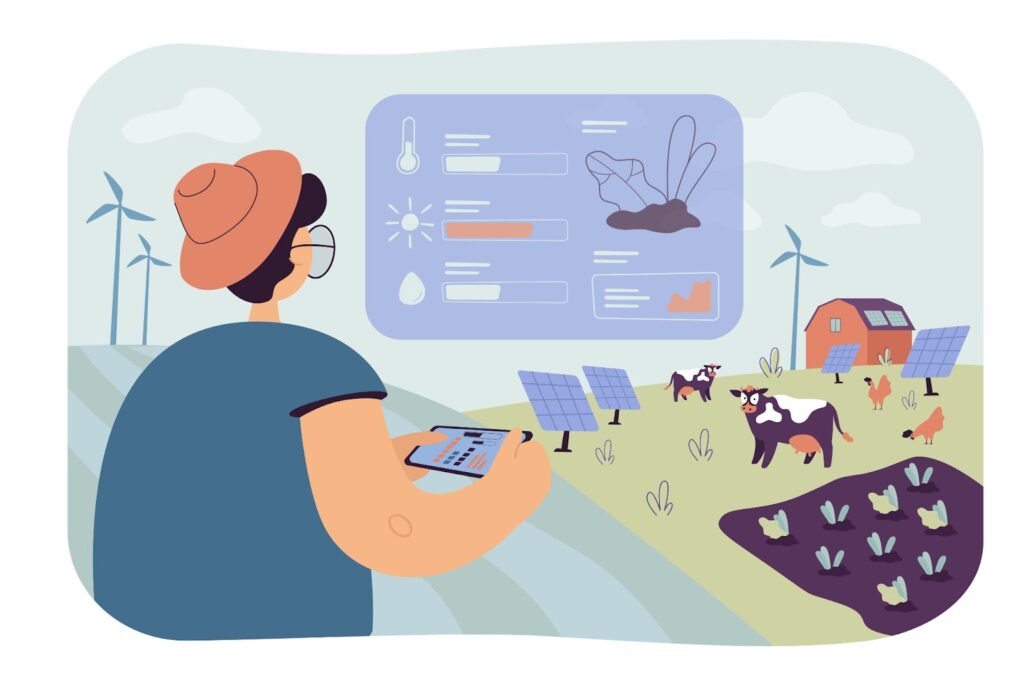

Predictive maintenance is a proactive strategy that uses data, sensors, and AI to monitor the condition of equipment in real-time. By analyzing data from various sources, such as machinery sensors, historical performance records, and environmental conditions, predictive maintenance can forecast when a machine is likely to fail or require servicing. This allows farmers to perform maintenance only when it is necessary, preventing unexpected breakdowns and minimizing downtime.

In agriculture, predictive maintenance systems typically involve equipping machinery with IoT sensors that collect data on parameters such as temperature, pressure, vibration, oil levels, and engine performance. This data is then fed into AI algorithms that analyze patterns and detect anomalies, providing early warnings of potential issues. As a result, farmers can schedule maintenance during off-peak times, reduce the risk of equipment failure during critical periods, and make better use of their resources.

Key Benefits of Predictive Maintenance in Agriculture

Minimizing Downtime:

One of the most significant advantages of predictive maintenance is the reduction of unplanned downtime. In agriculture, timing is everything—equipment breakdowns during planting, harvesting, or irrigation can lead to substantial financial losses. By predicting failures before they occur, farmers can avoid costly interruptions and ensure that their machinery is available when they need it most.

Extending Equipment Lifespan:

Predictive maintenance helps farmers extend the life of their equipment by identifying issues early, before they lead to major damage. This proactive approach reduces the wear and tear on machinery and allows for more targeted repairs, ultimately prolonging the usable life of the equipment and reducing capital expenditures on replacements.

Optimizing Resource Use:

Agricultural operations often involve the consumption of fuel, water, and other resources. Predictive maintenance not only keeps machinery in optimal working condition but also ensures that these resources are used efficiently. For example, a well-maintained irrigation system can reduce water waste, and a tractor with properly maintained engines can lower fuel consumption. This optimization leads to more sustainable farming practices and lower operational costs.

Reducing Maintenance Costs:

By performing maintenance only when it is necessary, predictive maintenance eliminates unnecessary servicing and repairs. This can significantly reduce maintenance costs over time. Furthermore, early detection of minor issues can prevent them from escalating into major, more expensive problems, saving farmers money in the long run.

Improving Decision-Making:

Data-driven insights provided by predictive maintenance systems give farmers a better understanding of their equipment’s performance. These insights can inform decisions about when to upgrade or replace machinery, which machines require the most attention, and how to allocate resources more effectively. By basing maintenance decisions on real-time data rather than guesswork, farmers can make more informed and strategic choices.

Harnessing AI and Data for Predictive Maintenance

AI and data analytics are at the heart of predictive maintenance systems. The combination of IoT sensors and AI-driven algorithms allows for continuous monitoring and analysis of equipment performance in real-time. Here’s how it works:

Data Collection:

IoT sensors are installed on agricultural machinery to collect data on various performance metrics. This data includes information such as engine temperature, fluid levels, vibration patterns, and machine speed. Environmental data, such as humidity and soil conditions, can also be integrated into the system.

Data Analysis:

Once the data is collected, AI algorithms analyze it for patterns and anomalies. Machine learning models are trained on historical data to recognize normal operating conditions and detect early signs of potential failures. For example, an increase in vibration or a decrease in oil pressure may indicate that a component is wearing out.

Predictive Insights:

Based on the analysis, the system generates predictive insights and alerts farmers about potential issues. These alerts can be as simple as a recommendation to check a specific component or as detailed as predicting the remaining lifespan of a part. The system can also provide maintenance schedules based on the actual condition of the machinery, rather than arbitrary time intervals.

Actionable Recommendations:

Predictive maintenance systems don’t just provide raw data—they offer actionable recommendations. For instance, if a tractor’s engine is running hotter than usual, the system might suggest checking the cooling system or scheduling an engine tune-up. These recommendations help farmers address issues before they lead to costly breakdowns.

Case Studies and Real-World Applications

Several agricultural businesses and equipment manufacturers have already embraced predictive maintenance to improve their operations. For example, John Deere, a leader in agricultural machinery, has integrated IoT and AI technologies into its equipment to enable predictive maintenance. Farmers using John Deere machines can monitor the health of their equipment remotely through the company’s connected platform, receiving real-time alerts and recommendations for maintenance.

In another case, a large-scale farm in the United States implemented predictive maintenance on its irrigation systems. By using IoT sensors to monitor water pressure and flow rates, the farm was able to detect issues such as leaks or blockages early, preventing water waste and reducing repair costs. As a result, the farm achieved a 15% reduction in water usage and a 20% decrease in maintenance expenses.

The Future of Predictive Maintenance in Agriculture

As AI and IoT technologies continue to advance, predictive maintenance will become an even more integral part of modern agriculture. The increasing availability of affordable sensors, improved data analytics, and cloud-based platforms will make it easier for farmers of all sizes to adopt predictive maintenance strategies.

Moreover, as predictive maintenance systems become more sophisticated, they will be able to offer even more accurate predictions and recommendations. For example, future systems may be able to account for weather forecasts, soil conditions, and crop growth stages when predicting equipment maintenance needs. This level of precision will further enhance the efficiency and sustainability of agricultural operations.

Conclusion

Predictive maintenance is revolutionizing the way farmers manage their equipment and resources. By harnessing the power of data and AI, farmers can extend the lifespan of their machinery, reduce downtime, and optimize the use of valuable resources like fuel and water. As the agricultural industry faces increasing pressure to produce more with less, predictive maintenance offers a practical and effective solution for improving efficiency and sustainability.

In the years to come, predictive maintenance will continue to be a driving force in the modernization of agriculture, helping farmers stay competitive, reduce costs, and operate more sustainably.

Arshon Technology is at the forefront of driving predictive maintenance innovations in agriculture by integrating advanced IoT sensors, data analytics, and AI-powered solutions. Through their cutting-edge technologies, Arshon enables farmers to monitor equipment health in real-time, detect potential issues early, and optimize the performance of their machinery. By leveraging Arshon Technology’s predictive maintenance systems, farmers can significantly reduce downtime, extend the lifespan of their equipment, and ensure the efficient use of resources, ultimately leading to more sustainable and profitable agricultural practices. As agriculture continues to evolve, Arshon Technology is poised to play a pivotal role in transforming farm management and boosting productivity.