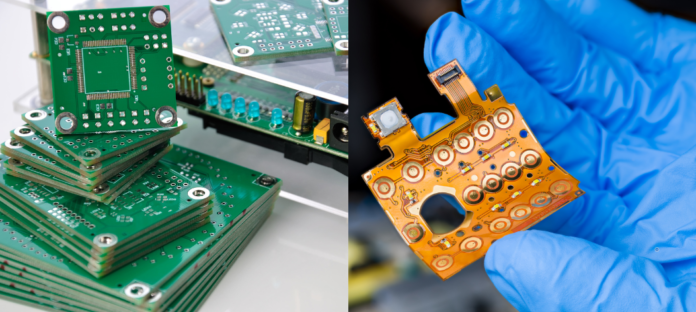

Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, supporting mechanical components and providing electrical interconnections. As technology advances, the demand for more versatile and compact electronic designs has resulted in two prominent PCB types: Rigid PCBs and Flexible PCBs. This article examines the characteristics, advantages, disadvantages, and applications of both types to help you make an informed decision for your specific needs.

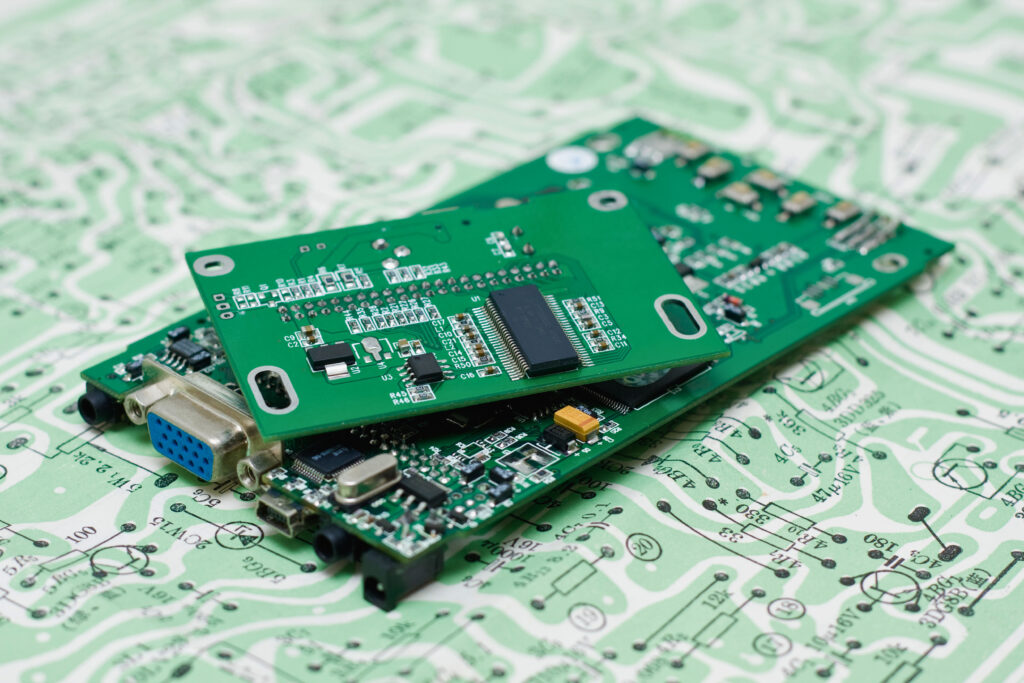

Understanding Rigid PCBs

Rigid PCBs are made from solid substrate materials, usually fiberglass or composite epoxy, that provide a robust base for electronic components. They come in various layer configurations, from single-layer to multiplayer, allowing for dense component arrangements. Rigid PCBs are widely used and have been proven reliable over decades.

Features of Rigid PCBs

Durability:

Rigid PCBs are built to withstand mechanical stress and high temperatures, making them suitable for harsh environments.

Electronic Performance:

With minimal signal loss and excellent heat dissipation, rigid PCBs are ideal for high-frequency applications.

Cost-Effectiveness:

Mass production of rigid PCBs often leads to lower costs per unit, making them a practical choice for consumer electronics.

Standardization:

They follow established manufacturing processes, ensuring consistency in quality and performance.

Applications of Rigid PCBs

Rigid Printed Circuit Boards (PCBs) play a crucial role in a wide array of applications across various industries, thanks to their robustness and reliability. Some of the primary applications include:

Consumer Electronics:

Rigid PCBs are integral to the functioning of everyday devices such as smartphones, televisions, and computers. They provide the necessary structural support for electronic components while facilitating efficient electrical connections, which is essential for device performance and longevity.

Telecommunications:

In the telecommunications sector, rigid PCBs are utilized in equipment like routers, switches, and servers. These boards ensure fast data transmission and stable connections, enabling seamless communication in both residential and corporate environments.

Automotive:

The automotive industry extensively employs rigid PCBs in control modules, dashboards, and infotainment systems. These PCBs are designed to endure the vibrations and temperature fluctuations typical in vehicles, making them critical for safety features, navigation systems, and driver assistance technologies.

Industrial Equipment

In industrial settings, rigid PCBs are key components of automation and control systems. They facilitate precise control over machinery, monitoring systems, and robotics, enhancing efficiency and productivity in manufacturing processes.

Beyond these applications, rigid PCBs are also found in aerospace systems, medical devices, and military equipment, where reliability and performance are paramount. As technology progresses, the demand for more sophisticated and compact rigid PCBs is expected to rise, further expanding their applications across diverse sectors.

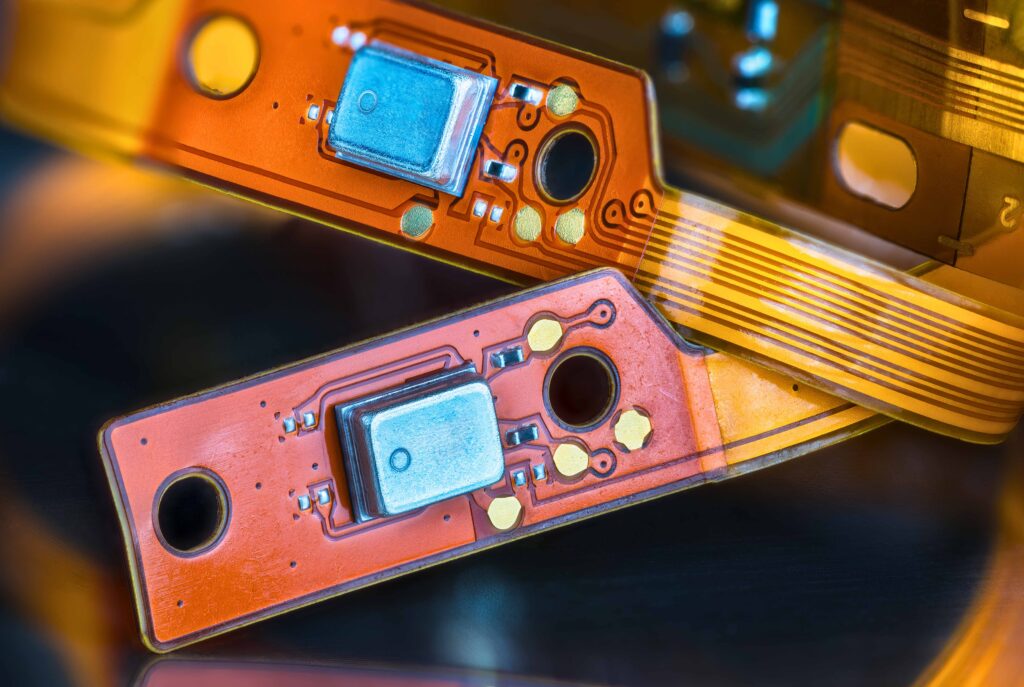

Exploring Flexible PCBs

Flexible PCBs are made from flexible materials like polyimide or polyester, allowing them to bend, twist, and fold without compromising functionality. These PCBs are typically lighter and thinner than their rigid counterparts, making them ideal for applications where space is limited.

Features of Flexible PCBs

Space Efficiency:

The ability to conform to different shapes enables flexible PCBs to fit into compact spaces, enhancing design flexibility.

Weight Reduction:

The lightweight nature of flexible PCBs contributes to overall weight savings in devices, which is crucial in applications like aerospace and medical devices.

Dynamic Performance:

Flexible PCBs can endure continuous bending and movement without failure, making them suitable for applications requiring dynamic flexibility.

Enhanced Cooling:

Their design can facilitate better heat dissipation, as flexible PCBs can be placed in areas where air circulation is maximized.

Applications of Flexible PCBs

Flexible PCBs (Printed Circuit Boards) have revolutionized various industries due to their adaptability and lightweight nature. They are increasingly utilized across multiple sectors, showcasing their versatility and functionality. Some prominent applications include:

Wearable Electronics:

Flexible PCBs are fundamental in modern wearables, such as smartwatches and fitness trackers. These devices require compact, lightweight components that can conform to the body, ensuring comfort and efficiency while monitoring health metrics.

Medical Devices:

In the medical field, flexible PCBs play a crucial role in devices like catheters and flexible sensors used for real-time diagnostics. Their ability to bend and adapt to different shapes is essential for minimally invasive procedures and accurate monitoring of patient health.

Consumer Electronics:

The popularity of flexible PCBs is evident in consumer electronics, particularly in smartphones and cameras. Their thin design allows for the integration of complex circuitry in compact spaces, leading to slimmer devices with enhanced functionality and improved performance.

Automotive Applications:

The automotive industry benefits from flexible PCBs in various ways, including sensor connections and LED displays. These boards can endure harsh environmental conditions, making them ideal for applications like dashboard displays and other critical vehicle monitoring systems.

Industrial Equipment:

Flexible PCBs are also utilized in industrial equipment where space is at a premium, such as machinery control systems and automation tools. Their ability to withstand vibrations and extreme temperatures ensures reliability in demanding environments.

Aerospace and Defense:

In the aerospace and defense sectors, where weight reduction and reliability are paramount, flexible PCBs are employed in advanced communication systems, radar units, and navigation devices. Their robust performance in challenging conditions helps enhance operational efficiency and safety.

The diverse applications of flexible PCBs across various sectors showcase their crucial role in technological advancement, facilitating the creation of smaller, lighter, and more efficient devices. As technology evolves, the demand for flexible PCBs will likely grow, driving further innovation.

Comparing Rigid and Flexible PCBs

Manufacturing Processes

The manufacturing processes between rigid and flexible PCBs differ significantly. Rigid PCBs typically follow a standard lamination process, while flexible PCBs often utilize a photolithography technique that allows for intricate designs and configurations. This difference can impact production timelines, costs, and design possibilities.

Design Complexity

Rigid PCBs can support high-density configurations and complex designs, benefiting applications with substantial space and less need for mobility. Conversely, flexible PCBs excel in designs that require a lightweight, adaptable configuration. Thus, your specific design needs can play a critical role in determining the right PCB type.

Cost Considerations

Initial costs for flex PCBs can be higher than rigid PCBs, particularly for smaller production runs. However, when considering the long-term benefits, such as reduced assembly time and material costs, flexible PCBs can be economical, especially in high-tech applications.

Reliability and Longevity

While both rigid and flexible PCBs are designed to withstand their particular environments, flexible PCBs face challenges such as fatigue from repeated bending, potentially leading to failure over time. Rigid PCBs are generally more robust, making them a reliable option for static applications.

Key Factors to Consider for Your Application

- Environmental Conditions: Assess where and how your PCB will be used. For conditions involving high temperatures, moisture, or mechanical stress, rigid PCBs may lend more reliability.

- Space Constraints: If your design must fit into a limited space or requires lightweight configurations, flexible PCBs could be the better choice.

- Movement Requirements: For applications involving frequent movement, such as wearables or robotic devices, flexible PCBs offer enhancements that rigid designs cannot.

- Production Volume: Evaluate your expected production numbers. Lower production volumes may favor flexible PCB designs despite higher upfront costs, while high volumes may benefit from the lower cost of rigid PCBs.

- Design Complexity: Understand the complexity of your electronic circuit. Projects demanding high-density and intricate designs may find rigid PCBs advantageous.

Conclusion

When choosing the right PCB for your application, it’s essential to weigh the unique characteristics, advantages, and potential limitations of both Rigid and Flexible PCBs. Rigid PCBs offer durability, cost-effectiveness, and ease of manufacturing, making them suitable for many standard applications. On the other hand, flexible PCBs provide unparalleled design flexibility, making them ideal for innovative and compact electronic devices.

Ultimately, your decision should be guided by your specific technical requirements, environmental conditions, production volume, and design complexity. By understanding the key differences and strengths of rigid and flexible PCBs, you’ll be better equipped to select the right type that meets the demands of your project. Time invested in this crucial decision can lead to improved performance, enhanced functionality, and greater manufacturing efficiency in your final products.