Selecting sensors for IoT applications starts long before you pick a part number. It begins with the use-case, the data you truly need, how that data will be translated into decisions, and how the whole chain will live on a PCB and in the field. If you work on pcb design, mechanical packaging, or embedded firmware, your choices today will shape accuracy, latency, lifetime, safety, and total cost tomorrow. This guide walks through a disciplined way to pick sensors that match real-world constraints without surprise trade-offs later.

Good selection habits follow a simple loop: define the job to be done → translate it into measurable inputs → shortlist sensor classes → model power, accuracy, and latency → validate interfaces and drivers → prototype and test in the environment where the device will live → instrument the product so you can recalibrate and update over time. Keep that loop in mind as you move through each section below.

Overview of sensor types (temperature, humidity, motion, light)

Temperature. The most common choices are thermistors (NTC/PTC), resistance temperature detectors (RTDs), and silicon temperature ICs. Thermistors are low-cost and sensitive in a narrow range. RTDs (e.g., Pt100, Pt1000) bring stable, wide-range behavior and better linearity with a proper excitation and instrumentation amplifier. Integrated silicon sensors offer I2C or SPI outputs, factory calibration, and low current, which helps in battery products.

Humidity. Capacitive polymer RH sensors dominate. They pair well with temperature sensing for dew point calculations. For dusty or corrosive air, choose packages with protective membranes and a replaceable hydrophobic filter. Be aware that humidity elements can drift when exposed to chemicals or persistent high humidity; pick parts with documented long-term stability and field calibration methods.

Motion. Options include passive infrared (PIR) for human presence, microwave Doppler modules for occupancy with through-material sensitivity, and inertial sensors (accelerometers, gyros, IMUs) for vibration and activity monitoring. PIR is low power but blind behind glass and sensitive to thermal gradients. IMUs are versatile but require digital filtering and careful layout to limit mechanical noise.

Light. Photodiodes and ambient light sensors (ALS) handle illumination control and lux logging. Consider human eye spectral response (V-lambda), infrared rejection, and angle of incidence. For color measurement, RGB or multispectral sensors can classify environments and detect changes such as leaf health in agritech or brand color compliance in retail displays.

Pressure and flow. MEMS barometers support altitude estimation and HVAC diagnostics. Differential pressure sensors enable filter monitoring and air or fluid flow calculations. For liquids, look at wetted-material compatibility, media-isolated diaphragms, and burst ratings.

Gas and air-quality. Electrochemical cells are selective but have finite life. MOS gas sensors respond to VOCs and need burn-in and baseline tracking. NDIR CO₂ sensors are stable and selective but draw more current. Plan for sensor warm-up and self-heating effects.

Proximity and ranging. Hall-effect sensors detect magnets for lid-open events. Time-of-flight (ToF) and structured-light sensors measure distance and occupancy with compact optics. Ultrasonic modules are inexpensive for short ranges but sensitive to wind and temperature.

Contact, force, and weight. Load cells with strain gauges plus instrumentation amplifiers measure mass with high resolution; force-sensitive resistors work for user input but drift over time.

Sound. MEMS microphones support audio events and machine diagnostics through acoustic signatures. Pick AOP (acoustic overload point) and SNR that match your environment.

Accuracy vs precision vs resolution

Resolution is the smallest step the system can report. Precision means repeatability. Accuracy is closeness to the true value. Many engineers mix them up, which leads to errors in interpreting readings. A high-resolution ADC does not guarantee accuracy if the sensor or reference drifts. Always test sensors under the actual operating environment and temperature range.

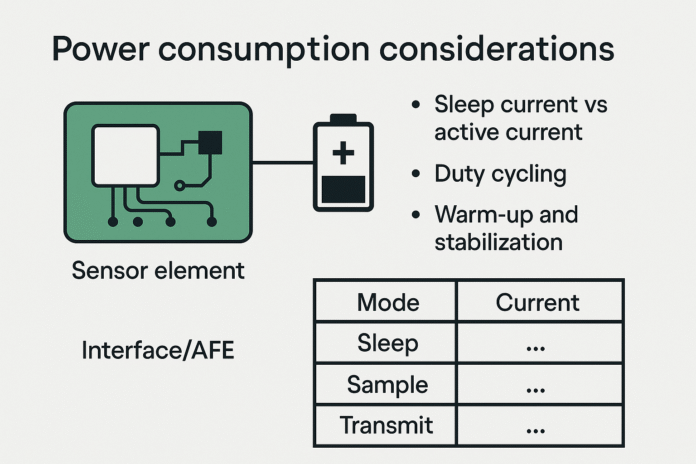

Power consumption considerations

Battery or energy-harvesting products live and die by the current budget. Map power at three levels: the sensor element, its interface/AFE, and the host’s sampling and processing.

Key levers:

• Sleep current vs active current

• Duty cycling

• Warm-up and stabilization

• Supply choices

Build a simple table for each mode (sleep, sample, transmit) and compute average current. This practical step prevents unexpected battery drain.

Interface options: I2C, SPI, UART, analog

I2C is ideal for multiple low-speed devices; SPI supports high speed and low latency; UART handles longer runs and simple ASCII protocols; analog remains standard for legacy and industrial sensors. Match interface choice with cable length, EMC environment, and required throughput. From a pcb design perspective, route differential pairs tightly and add test pads for debugging.

Calibration and drift over time

Every sensing element drifts. Plan for calibration from day one. Store factory coefficients, use temperature compensation, and log drift metrics. For high-value assets, design sockets for sensor replacement. Never rely on initial calibration alone; field recalibration keeps your network data trustworthy.

Environmental constraints (humidity, temperature, vibration)

Environments define lifetimes. Protect against moisture, vibration, and chemicals using IP-rated housings, conformal coatings, compliant mounts, and UV-stable materials. Validate sensors under real stress: vibration tables, humidity chambers, and thermal cycles. Even small mechanical coupling can distort accelerometer or pressure readings.

Security considerations in sensor data

Sensors are part of the attack surface. Apply signed firmware, redundant validation, and anomaly detection. Treat every input as untrusted data. Add plausibility checks (e.g., humidity cannot exceed 100%) and detect replay attempts with timestamps or nonces.

Interoperability and communication protocols

Sensors must speak to gateways. Match your use case to the right stack: BLE, Wi-Fi, Thread, Zigbee, Matter, LoRaWAN, or Modbus. Consistency of data model and units is essential; document your schema and maintain backward compatibility for firmware updates.

Selecting sensors for smart home applications

Smart home devices prioritize cost, power, and aesthetics. Combine temperature, humidity, and motion detection in small packages. Focus on low leakage currents and integrated calibration. For user trust, display diagnostic data and expected sensor lifetime in the app interface.

Selecting sensors for industrial IoT

Industrial sites need reliability, certifications, and compatibility. Choose accelerometers for vibration diagnostics, differential pressure sensors for flow, and certified gas detectors for safety zones. Add standard interfaces (4–20 mA, RS-485/Modbus) and protection against surge, EMI, and oil exposure.

Testing and validation

No datasheet replaces testing. Run sensors through bench calibration, temperature/humidity stress, mechanical vibration, and EMC exposure. Keep “golden units” to benchmark new batches. Testing reveals behavior under the full lifecycle and validates software compensation models.

Practical pcb design tips for sensor reliability

Separate analog and digital grounds, provide low-drift voltage references, and protect inputs with RC filters and TVS diodes. Avoid self-heating near temperature sensors and provide footprints for tuning filters. Add diagnostic test points accessible during field maintenance.

Supply chain and lifecycle thinking

Select sensors with multiple sources, long availability, and active manufacturer support. Use modular sensor boards for easy replacement. Document calibration data, serial numbers, and part revisions for traceability.

Conclusion

Good sensor selection is less about chasing the highest specification and more about aligning technology with purpose, environment, and lifecycle. Start from the application, map performance requirements, test early, and calibrate throughout the product’s life. Combine sound electrical design, robust packaging, and thoughtful firmware to maintain accuracy and reliability in real-world IoT systems. When sensors, pcb design, and software operate in harmony, the result is a resilient device that delivers dependable data for years.