Printed Circuit Boards (PCBs) are the unsung heroes of modern electronics, functioning as the foundation for virtually every electronic device we use today. Whether it’s a smartphone, a computer, or even a microwave oven, PCBs are essential to ensuring smooth electrical connections between various components. While some applications require complex, multilayer designs, there is still a significant need for single-sided PCBs due to their simplicity, ease of production, and cost-effectiveness. This article will explore single-sided PCBs, their characteristics, their importance in PCB design, and how they continue to serve in a variety of applications.

Understanding the Basics of Printed Circuit Boards

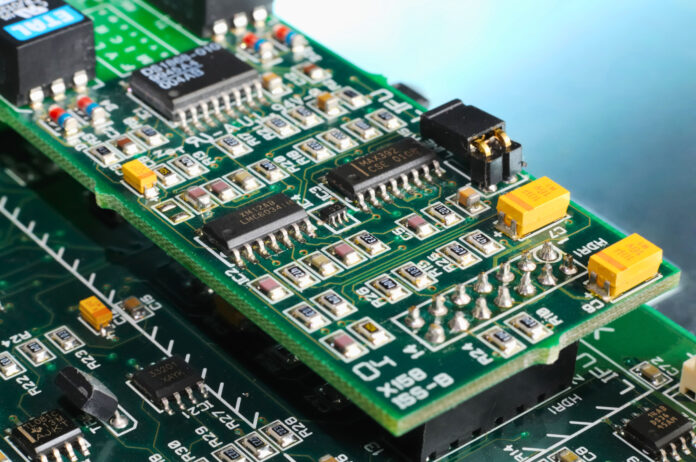

Before delving into the specifics of single-sided PCBs, it’s essential to understand the general structure of a Printed Circuit Board (PCB). A PCB is a board that mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features. These conductive features are etched from copper sheets laminated onto a non-conductive substrate. Components such as resistors, transistors, capacitors, and integrated circuits (ICs) are generally soldered onto the PCB to establish electronic circuits.

PCBs are categorized based on the number of layers of conductive copper they have. These layers include the substrate (usually made from materials like fiberglass) and the copper foil layer, where the circuits are printed. There are different types of PCBs, including single-sided PCBs, double-sided PCBs, and multilayer PCBs.

What is a Single-Sided PCB?

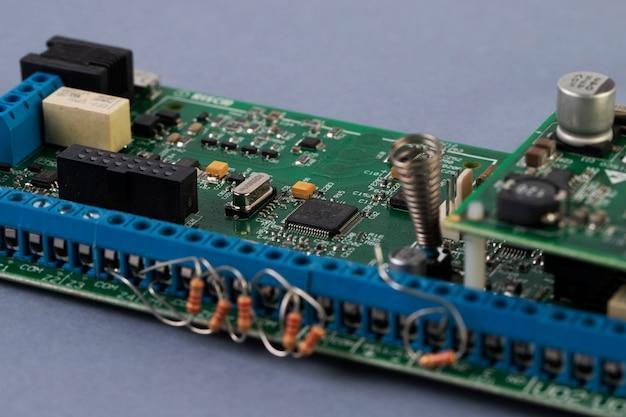

A single-sided PCB is the most basic type of PCB and consists of only one layer of conductive copper material. The other side of the board typically features a non-conductive substrate or an insulating material, such as fiberglass (FR4), phenolic, or a plastic-based substance. In single-sided PCBs, the electrical components are placed on one side of the board, while the copper traces or pathways, which establish the electrical connections, are etched onto the opposite side. Since there is only one conductive layer, this type of PCB is known for its simple structure and low cost.

One of the most recognizable features of a single-sided PCB is that it doesn’t have vias or plated-through holes. Vias are tiny holes that allow electrical connections between multiple layers of a PCB. In single-sided PCBs, all connections occur on one side, eliminating the need for these additional steps.

How Single-Sided PCBs Work?

The design of a single-sided PCB is relatively straightforward compared to other types of PCBs. Electrical components, such as resistors, diodes, capacitors, and transistors, are mounted on the non-conductive side of the board. The copper traces, which connect the components to form an electrical circuit, are etched on the opposite side of the board. These copper pathways create the necessary electrical connections between different components to allow current to flow and perform the desired function.

The assembly of single-sided PCBs usually involves a process called through-hole technology, where the leads of electronic components are inserted through drilled holes and soldered to the copper tracks on the other side. Surface-mount technology (SMT) can also be applied in single-sided PCBs, although this is more commonly seen in more complex designs like double-sided or multilayer boards.

PCB Layers: Single-Sided PCBs vs. Multilayer PCBs

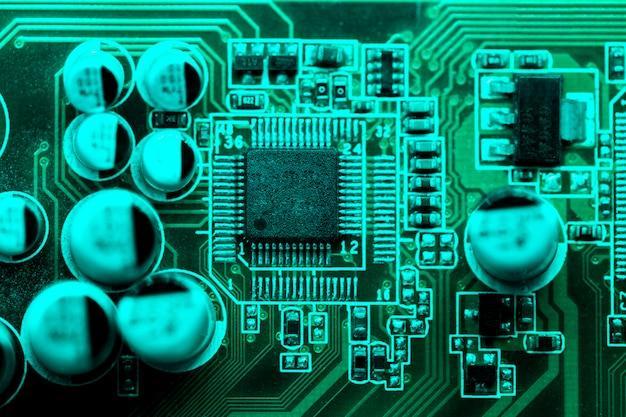

In the world of PCBs, the term PCB layers refers to the number of copper layers present in a PCB. A single-layer PCB has just one conductive layer, while multilayer PCBs can have anywhere from two to over 50 layers. The number of layers in a PCB impacts the overall functionality, complexity, and size of the final electronic device.

- Single-layer (single-sided PCBs): These PCBs have only one layer of conductive copper, and components are mounted on one side of the board.

- Double-layer (double-sided PCBs): These PCBs have conductive copper traces on both sides of the board, with components and connections on both sides.

- Multilayer PCBs: These PCBs consist of multiple conductive layers separated by insulating layers, allowing for more complex circuits and designs.

While multilayer PCBs are widely used in high-performance and high-density electronics like smartphones, computers, and advanced communication systems, single-sided PCBs are still commonly used in simpler devices that do not require the complex routing and space-saving benefits provided by multilayer designs.

Advantages of Single-Sided PCBs

Single-sided PCBs offer several distinct advantages, particularly for simpler electronic applications. These benefits include:

1. Cost-Effective

One of the primary advantages of single-sided PCBs is their cost-effectiveness. Since they only require one layer of copper and fewer materials overall, they are cheaper to manufacture compared to double-sided and multilayer PCBs. This makes them an ideal choice for mass production of low-cost electronic devices.

2. Simplicity in Design

Single-sided PCBs have a straightforward design process. With only one conductive layer to manage, designers do not have to worry about interconnecting multiple layers or creating complex layouts. This simplicity results in shorter design cycles, making single-sided PCBs ideal for projects where quick turnaround times are essential.

3. Easy Manufacturing and Assembly

The lack of vias or plated-through holes in single-sided PCBs simplifies the manufacturing process. With only one conductive layer, there are fewer steps involved in production, reducing both the time and cost required to create these boards. This also translates to easier assembly, as components are mounted on just one side of the board.

4. Durability for Basic Applications

While single-sided PCBs lack the complexity of multilayer designs, they are more than adequate for many basic applications. These boards are often more durable in environments where electrical demands are lower and fewer components are required. Their simplicity makes them more reliable in devices where complex routing is unnecessary.

Common Applications of Single-Sided PCBs

Despite the prevalence of multilayer PCBs in advanced electronics, single-sided PCBs still serve a critical role in various industries, particularly for simpler devices and applications that don’t require the intricate designs offered by multilayer boards. Common applications of single-sided PCBs include:

1. Consumer Electronics

Many simple consumer electronics, such as calculators, remote controls, radios, and basic household appliances, rely on single-sided PCBs. These devices do not require high-performance circuitry, making single-sided boards an economical choice.

2. Power Supplies

Power supplies and battery chargers frequently use single-sided PCBs. These applications generally require straightforward circuits with fewer components, making single-sided boards ideal for providing reliable performance.

3. LED Lighting Systems

LED lighting systems are another major area where single-sided PCBs are extensively used. The simple electrical connections required to power and control LEDs can be effectively handled by single-sided PCBs, which helps keep production costs down while delivering reliable performance.

4. Automotive Applications

In the automotive industry, certain low-complexity systems, such as dashboard indicators, interior lighting, and basic control systems, use single-sided PCBs. Their durability and cost-effectiveness make them suitable for these non-critical applications.

Limitations of Single-Sided PCBs

While single-sided PCBs have their advantages, they do come with some limitations. These include:

1. Limited Functionality

Due to their single layer of copper, single-sided PCBs can only handle simpler circuits and cannot support complex routing requirements. This makes them unsuitable for high-performance applications that demand greater complexity, higher data rates, or multiple interconnections.

2. Size Constraints

With only one side available for components and connections, single-sided PCBs require more physical space for more intricate designs. This makes them less ideal for applications where miniaturization is crucial.

3. Limited Current Carrying Capacity

Single-sided PCBs have a lower current-carrying capacity compared to their multilayer counterparts, as they lack the additional copper layers that can distribute current more effectively. This limits their use in high-power applications.

Conclusion

Single-sided PCBs remain an integral part of the electronics industry, offering a cost-effective and efficient solution for many applications that do not require the complexity of multilayer boards. Their simplicity in design, ease of manufacturing, and low production cost make them a practical choice for various consumer electronics, power supplies, and LED systems. While they may not provide the advanced functionality needed for high-performance devices, their role in the development of simple, reliable electronics is indispensable.

For industries looking for a balance between simplicity and functionality, single-sided PCBs continue to deliver, proving that sometimes the simplest solutions are the most effective.