Surface-mount vs through-hole design decisions shape everything from performance to lead time, rework strategy, tooling, and cost. If you work in pcb design, test planning, or manufacturing operations, the choice between SMT and THT affects your BOM, panel utilization, inspection steps, supply risk, and even field reliability. This article breaks down how each approach behaves on the bench and on the line, where mixed technology shines, and what to watch when tuning footprints, panel arrays, reflow profiles, or wave processes. You’ll find design rules that shorten ramp time, cut defects, and keep your product ready for scale without painting you into a corner during prototypes.

History of SMT and THT technologies

Through-hole technology (THT) was the default method for decades. Components with axial or radial leads pass through drilled holes and are soldered on the opposite side by wave solder or hand solder. Early consumer and industrial products favored THT because it offered clear visual inspection, strong mechanical anchoring, and easy hand assembly with minimal automation. As devices grew smaller and denser, drilling costs, board size, and manual labor became the bottleneck.

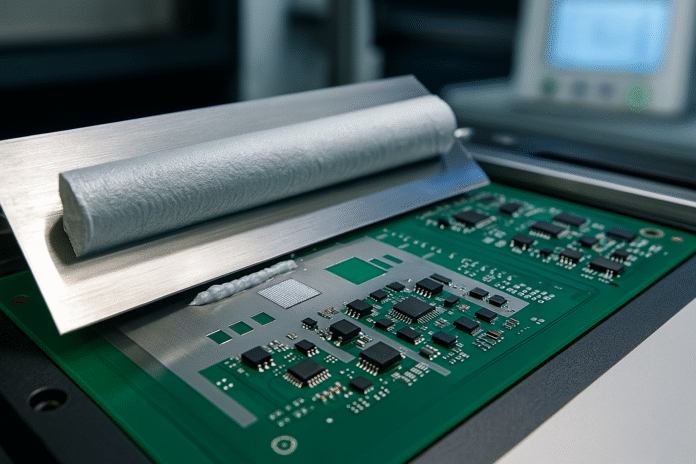

Surface-mount technology (SMT) arrived to raise circuit density and line throughput. Instead of drilling a hole for every lead, parts are placed on pads with solder paste and reflowed in an oven. Pick-and-place machines, solder paste printers, AOI, and X-ray systems created a fast, repeatable path for high-volume builds. By the mid-1990s, passive components and most digital ICs had moved to SMT, while high-power or high-stress items often stayed THT for mechanical reasons. Today, almost all high-volume electronics rely on SMT first, with THT reserved for connectors, large electromechanical parts, special passives, and high-reliability items.

Advantages and disadvantages of SMT

Why teams choose SMT

• Higher density: small packages (0402, 0201, μBGAs, QFNs) reduce board area and enable compact enclosures.

• Faster automated assembly: paste printing and reflow let machines place thousands of components per hour with consistent results.

• Lower drill count: fewer holes means lower PCB drilling time, improved routing freedom, and simpler stack-ups.

• Better electrical behavior for high-speed signals: short interconnects, low lead inductance, and compact loops aid signal integrity and power distribution.

• Rework at scale: while tiny, SMT joints are standard for automated inspection and rework with hot-air or IR equipment, and AOI/X-ray can spot common defects quickly.

Tradeoffs to manage

• Smaller pads magnify manufacturing variation: tombstoning on small passives, bridging on fine-pitch parts, voiding on large thermal pads, and sensitivity to paste volume.

• Thermal mass balance matters: uneven copper can skew parts during reflow; stencil and layout tuning are needed.

• Mechanical strength: small pads alone provide limited pull strength; heavy or stressed parts may require glue dots, underfill, or mechanical retention.

• Hand-assembly difficulty: fine-pitch parts and micro passives are tedious for manual builds, which affects early prototypes without access to a reflow line.

• Repair visibility: leadless packages (QFN, many BGAs) demand X-ray for hidden joints, adding equipment and skills to the toolbox.

Mechanical strength considerations

Mechanical loads come from shock, vibration, cable insertion, thermal cycling, and user interaction.

• Connectors and controls: where users plug, press, or twist, THT pins anchor forces through the board thickness and into plated barrels. SMT options with through-board pegs, metal shields, or hold-downs reduce peel stress on pads. For USB-C, RF coax, and card sockets, use metal tabs, multiple mounting points, and keepouts around the shell for rework access.

• Mass and center of gravity: heavy transformers, big inductors, and tall electrolytics can rock during vibration; THT provides better retention. If SMT is required, add mechanical brackets, epoxy staking, or underfill.

• Thermal cycling: CTE mismatch between component bodies and copper pads can fatigue joints. Gull-wing leads (SOIC/TQFP) tolerate strain better than leadless packages. For harsh environments, apply corner bonding to QFN/LGA devices and add stiffeners on flex or thin PCBs.

• Solder joint geometry: THT joints form fillets through the barrel, adding shear strength; SMT pads rely on pad pull strength and fillet shape. Use larger pad fillets and teardrops where possible, and avoid mask-defined pads for parts that see side loads.

Manual vs automated assembly

Manual assembly sweet spots

• Early proof-of-concept and low-mix, low-volume runs.

• THT connectors, tall components, and odd-form parts where hand solder is straightforward.

• Rework or ECO builds when footprints are large and spacing is generous.

Automated assembly sweet spots

• Consistent high-volume SMT placement with minimal touch time.

• AOI and X-ray coverage for yield feedback and process tuning.

• Selective solder or wave for THT where pin counts are high.

Hybrid lines

Many factories print paste and place SMT first, reflow, then handle THT by selective solder or wave. Fixture design, palletization, and process order matter: don’t let tall THT parts shadow nearby SMT during wave; space them to maintain proper solder wave contact. Panels should include rails and tooling holes for conveyors and selective solder fixtures.

Throughput thinking

Cycle time on the line depends on the longest operation. Short changeovers favor SMT with common feeders and shared footprints. THT dominated by hand steps can stall high-mix production unless selective solder fixtures are prepared in advance.

Mixed-technology boards

Mixed boards pair SMT for density and speed with THT for mechanical anchoring or high power. Key habits:

• Plan the order: SMT → reflow → THT insert → selective solder/wave → hand touch-up → wash (if water-soluble) → conformal coat (if used) → test.

• Keepouts: reserve space around wave-soldered parts; avoid SMT on the wave side near tall THT leads that can disturb solder flow.

• Thermal shields: when selective soldering, use pallets and masks that protect nearby SMT from heat and flux.

• Double-sided builds: if both sides have SMT, pick lighter components for the second reflow side or use adhesives for gravity hold during the second pass.

• Labeling and traceability: place labels where they survive cleaning and are visible to AOI/test; avoid putting labels across score lines or mouse-bites.

Design guidelines for SMT footprints

Footprint quality drives yield. Build a central library and align with your assembler’s rules.

• Follow vendor land patterns, then tune: begin with the datasheet recommendation; cross-check with IPC-7351, your stencil thickness, and paste type.

• QFN thermal pads: segment the thermal pad paste to about 50–70% total area with windowpane openings to reduce float and voids; plate-filled and capped vias (VIPPO) or tented microvias prevent paste wicking.

• Small passives: balance pad sizes to curb tombstoning; keep copper symmetry and consider slight aperture reduction on the hotter pad.

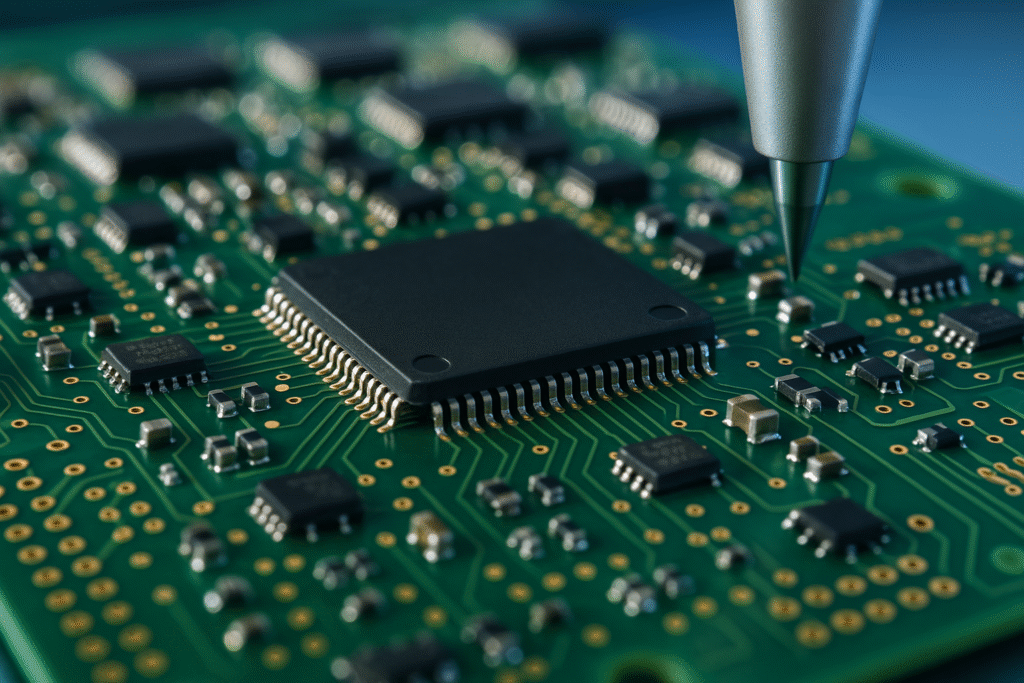

• BGAs and fine pitch: add two local fiducials near the device; match mask expansion to registration capability. Decide early between dog-bone escapes and via-in-pad (filled/planarized).

• Polarity and pin-1 marks: use solid shapes visible after assembly, not just text. Align orientations to reduce placement mistakes.

• Height and keepouts: maintain 3D models with accurate heights; check clashes with shields and enclosures.

• Paste-mask strategy: rounded aperture corners aid release; consider nano-coated stencils for tight features, and step-downs where both 0.4 mm pitch and large power pads share a panel.

• AOI readability: reference designators near components, text larger than the fabricator’s minimum, and consistent silkscreen contrast.

Rework and prototyping considerations

Prototyping

• THT is friendly for breadboards and hand mods. It tolerates multiple solder cycles, jumper wires, and bodges.

• SMT prototypes run best when you have access to a paste printer, reflow oven, or hot-plate/hot-air combo and good tweezers. For very small passives, order stencils even for early spins; manual paste with syringes is slow and uneven.

• Combine SMT for ICs and passives with a few THT connectors and test headers to speed lab work.

Rework

• Gull-wing SMT is straightforward with hot air and solder wick.

• QFN needs preheating and controlled hot air; keep the thermal pad from tearing pads during lift.

• BGA rework requires a bottom heater and profile control; X-ray confirms ball wetting and bridges.

• THT rework is simple when access is clear; multi-pin connectors with ground planes need strong preheat and good wicking tools.

Pad durability

Excess heat or repeated rework can lift SMT pads. Design for fewer rework cycles: add test points, program headers, and clearances so faults are found early at low risk.

When to choose through-hole components

Even in modern products, THT remains the right call for certain needs:

• High mechanical load: power jacks, toggle switches, high-cycle connectors, large relays, and big magnetics.

• High voltage creepage/clearance: THT can provide larger conductor spacing and lead shape control for safety approvals.

• High temperature or atypical soldering: some parts are not reflow-safe; THT keeps them off the reflow profile.

• Field serviceability: THT is easier to desolder and replace with basic tools; ideal for service depots and long-life equipment.

• Legacy or certification lock-in: if a certified product revision must keep certain part numbers and packages, THT avoids a new lab path.

• Audio and precision analog: some designers prefer THT film capacitors or precision resistors for stability and noise performance; availability and physical size drive the choice.

SMT in high-frequency applications

For RF and high-speed digital, SMT shortens current loops and reduces parasitics.

• Package parasitics: shorter leads and lower inductance improve return paths and reduce ringing. QFN and LGA bodies with exposed pads help ground stitching and heat spread.

• Controlled impedance: SMT allows tight trace geometries and via stubs control. Keep component pads short to reduce discontinuities.

• Passive selection: use C0G/NP0 capacitors and thin-film resistors with stable parasitics; avoid long leaded parts that introduce excess inductance.

• Shielding and keepouts: plan SMT-friendly shields with removable lids; keep edge clearance for lids and fence vias.

• Finish: ENIG or ENEPIG offers flat pads for fine pitch and reliable RF contact; immersion silver is an option with proper handling to avoid tarnish.

• Thermal: RF power devices often need tight thermal paths; SMT with VIPPO under the die pad improves heat removal compared to tall THT leads.

Cost implications of SMT vs THT

Cost is not just part pricing. It reflects placement rate, defect rates, rework, inspection, and test time.

• Labor and line time: SMT reduces human touch per board; line time becomes predictable once stencils, feeders, and programs are dialed in. THT with many pins increases labor unless selective solder or wave can process groups at once.

• PCB fabrication: SMT lowers drill counts and may allow thinner boards or fewer layers by improving routing freedom. THT adds drilled holes and sometimes additional copper for barrel reliability.

• Tooling: SMT needs stencils and possibly step stencils; THT may need selective solder pallets or wave fixtures. For multi-variant products, shared SMT footprints and feeder setups cut changeover cost.

• Quality and scrap: AOI and X-ray catch SMT issues early. THT problems often surface during functional test if wave profiles or lead lengths vary. Hidden rework cost can dominate when connectors are mis-aligned or shadowed.

• BOM strategy: SMT parts usually have wide availability and second sources; THT specialty items can be single-sourced. Risk matters as much as unit price.

• Total landed cost: look past per-part savings. A THT connector that requires manual solder on both sides adds minutes per unit; over thousands of units, line time dwarfs a small part price difference.

Future of PCB assembly technologies

The trend continues toward smaller SMT, higher placement accuracy, and smarter inspection. A few shifts to plan for:

• 01005 and smaller passives: more products are adopting very small passives; footprints and stencil design must be tuned to avoid skew.

• Advanced packages: fan-out and system-in-package solutions push more functionality into small areas, often LGA or wafer-level CSP. Library discipline and X-ray access become non-negotiable.

• Selective solder advances: better nozzle control and pallet designs make THT faster with less spatter and heat exposure, enabling more mixed-tech boards without heavy hand labor.

• Low-temperature solders: bismuth and other alloys reduce thermal stress on parts and plastics; reliability testing and profile control are important.

• Inline test and data: more factories connect AOI, SPI, and ICT results to dashboards, feeding design rules back to libraries so each spin starts stronger.

• Additive and embedded technology: printed passives, embedded magnetics, and rigid-flex growth change how footprints and mechanicals interact; plan footprints and keepouts that tolerate folding and strain.

• Sustainability and repairability: regulations and customer expectations are pushing designs toward easier disassembly and material disclosure. THT may gain favor for serviceable modules in certain sectors, while SMT dominates where compact form factor is the story.

Decision matrix: picking SMT, THT, or both

A practical selection grid helps align teams:

• Performance: high-speed or RF → favor SMT; high power or high current with big thermal paths → either SMT with heat-spreading pads or THT with thick barrels.

• Strength: user-facing connectors and controls → THT or SMT with strong mechanical tabs and metal shells.

• Manufacturing: high volume with stable demand → SMT; low volume with frequent ECOs → mix SMT for passives/ICs and THT for user connectors.

• Service: field replacement expected → THT for replaceable modules; sealed consumer product → SMT.

• Cost/time-to-market: quick ramp and shared line setups → SMT; special parts with few pins and low counts → hand-insert THT if volume is small.

• Regulatory: safety spacing, creepage/clearance, or high voltage → THT often simplifies approvals; low-voltage digital → SMT everywhere.

Practical SMT layout and process tips

• Align orientations for common rotation and easier placement programs.

• Place local fiducials near fine-pitch parts; add global fiducials to panel rails.

• Balance copper around small passives to reduce tombstoning; use thermal relief on large copper fills.

• Reserve rework access: 1–2 mm around tall parts; avoid crowding connectors with tiny passives.

• Segment QFN thermal pads; reduce total paste area; prevent via wicking with VIPPO or tenting.

• Match finish and stencil thickness to pitch.

• Add test pads for power rails, reset, clocks, and programming.

• Plan shields early and leave clearance for lids and screws.

Practical THT layout and process tips

• Keep pin length consistent for wave solder; trim leads to the fabricator’s recommended stick-out.

• Angle parts where needed to match conveyor direction and improve wave contact.

• Maintain proper keepouts around wave-side SMT; tall THT leads can cause shadowing and turbulence.

• Add tooling holes and rails for selective solder fixtures; specify nozzle sizes and solder mask clearance around pads.

• Use teardrops on pads into heavy planes to reduce barrel cracks from thermal stress.

• Place serviceable parts near the board edge; leave room for pullers and desoldering tools.

• For high current, ask the board house for barrel wall thickness capability; set accept criteria in drawings.

Case examples: choosing wisely

Wearable sensor: small enclosure, battery powered, tight routing, and high-speed MCU with external memory. Decision: SMT only, QFN and fine-pitch passives, ENIG finish, two-sided reflow, no THT except a small battery connector with SMT hold-downs.

Industrial motor controller: high current, vibration, and field service expected. Decision: SMT logic and passives; THT for bus bars, high-current terminals, large film capacitors, and transformers. Selective solder pallets reduce touch time. Conformal coat after test.

Consumer router with USB-C: RF channels and user-facing connectors. Decision: SMT for RF front-end and digital SOC; SMT USB-C receptacle with through-board pegs and metal shell; extra retention screws on the enclosure to offload pad stress.

Quality, inspection, and test

• AOI/SPI: measure paste volume and placement before reflow; small adjustments to stencil and program fix half of early defects.

• X-ray: mandatory for BGA and helpful for QFN void analysis. Keep library paste rules tied to X-ray outcomes.

• Functional and boundary scan: add headers and scan chains; they reduce no-fault-found rates and speed coverage growth across spins.

• Thermocouples: profile the board itself, not just a coupon. Record ramp, soak, peak, and time above liquidus; keep the trace with the build record.

• Selective solder validation: run coupons with mixed lead lengths and nearby SMT to validate pallet shields and nozzle height.

Collaboration with your CM

Early feedback saves reroutes and re-fixtures.

• Share preliminary BOM, Gerbers, STEP, and assembly notes before layout freeze.

• Ask for stencil thickness, paste brand, and fiducial preferences; match your library to the line.

• Define acceptable alternates in the AVL to avoid supply shocks.

• Provide golden units and test scripts; keep revisions synchronized in PLM.

• Track first-pass yield, defect Pareto, and rework time; convert repeat issues into library updates.

Conclusion

Surface-mount vs through-hole design decisions are not a binary vote. Smart products use SMT for speed, density, and electrical behavior, then add THT where mechanical strength, serviceability, or safety spacing demand it. Map the choice to real process limits, not just preferences: stencil thickness, wave access, selective solder fixtures, inspection capability, and test coverage. Build a strong library, tune paste apertures and pad geometry, keep rework access open, and maintain a clean handoff to your contract manufacturer with panel rails, fiducials, and clear assembly notes. Treat each build as data, feed outcomes into your rules, and your next spin will pass through the line quicker with fewer surprises and lower total cost.