After the COVID-19 outbreak, many industries are still struggling to purchase electronic components. Due to a shortage of raw materials for producing electronic components and circuit boards, many companies were closed. PCB design companies and PCB manufacturers are struggling to manufacture their products.

Finding a potential manufacturer who will bring your desired printed circuit board design to life is challenging. Technology has stepped up with devices to fulfill this purpose.

An advanced device can design your PCB professionally and effectively. It also eliminates the cost, and these devices are specifically designed to meet the user’s requirements.

Advanced PCB Manufacturer

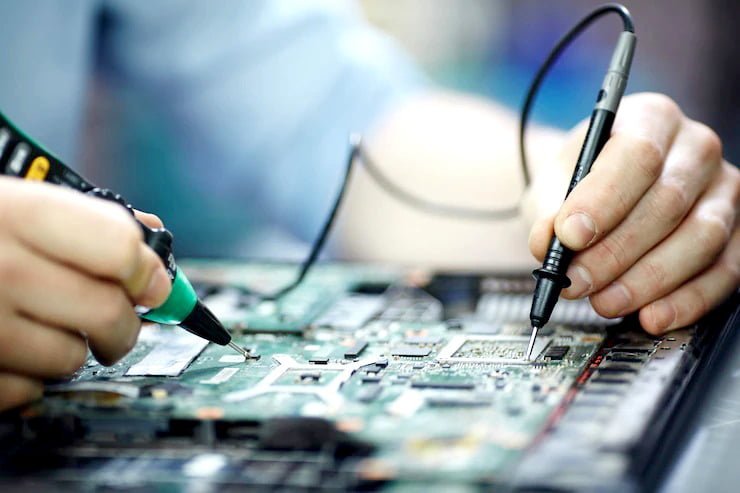

The manufacture of PCB requires the input of an expert to undermine flaws in the design. A PCB manufacturing company helps its clients to make a mark with not merely their designs but programming the integrated circuits, prototyping, etc.

Let’s discuss some important machines in PCB manufacturing:

Pick and Place

These machines generate good quality in a short interval of time. They arrange the electronic components in their respective places too. More importantly, human effort is denied in this.

X-Ray Machine that counts the number of components

X-ray machines are great for imaging; they produce amazing quality. Other than that, they count the number of components effectively so that great PCB results are produced.

X-Ray Machine for 3D PCB inspection

A 3D x-ray framework can make 3D pictures of a PCB by developing a progression of 2D cross-sections. It includes a camera that can change the wide-point circuit board to show at high amplification.

Challenges for Advanced Equipment

A supply chain is the biggest challenge. For example, if any piece of the final product is unavailable, it will break the chain, and the final product will not be available. In recent years, especially after COVID-19, the shortage of electronic components has become a global problem.

When the use of advanced equipment is increased, it reduces human labor immensely. Other than that, it requires the constant support of a monitor. If there is even a minor glitch or inconsistency, the chances of damage are increased.

As mentioned earlier, many companies have stopped manufacturing due to the unavailability of supplies. So, it has increased the demand for ICs. All these challenges have increased the final prices of the products. Finally, the delivery time isn’t only delayed, but the shipping costs are also increased.

What’s the Solution?

The following tips can help you cope with the challenges mentioned above.

- Plan and order parts ahead of time.

- Buy as much stock as possible to fulfill customer orders.

- If you want to keep the process running, ensure that you have enough options.

- Have multiple vendors so that if one part is short or unavailable at one vendor, you can contact the other.

Conclusion

Using upgraded devices brings accurate and satisfying results. These devices have less chance of error, and by the nature of electronics, it does repetitive work precisely. So, understand the supply and demand challenges and take action accordingly.