Introduction

Printed Circuit Boards (PCBs) form the backbone of virtually all modern electronic devices. Whether you are dealing with consumer electronics, industrial machinery, communication devices, or aerospace systems, a robust and reliable PCB design is essential to ensure consistent functionality. One of the most widely used materials in PCB fabrication is FR4, an industry-standard laminate that has shaped how electronic assemblies are designed and produced for decades.

This article aims to explore PCB board material FR4 in detail, from its properties and specifications to densities, thicknesses, and comparison charts. Additionally, we will discuss the significance of PCB material density, how to reference or create a PCB material density chart, how to work with a PCB material density formula, and how you might use a PCB material density calculator. By the end, you should have a thorough understanding of FR4 and its pivotal role in the electronics industry, enabling you to make more informed decisions when designing or selecting PCBs.

FR4 Material Properties

Composition

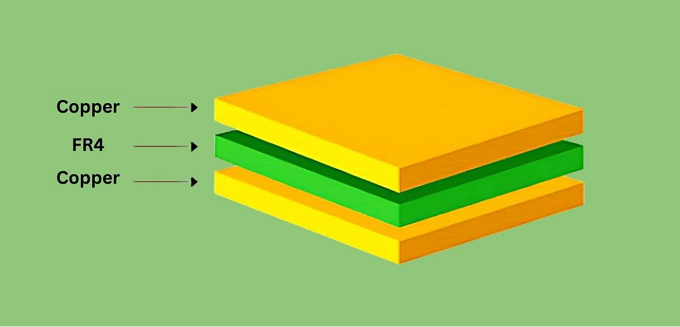

FR4 stands for “Flame Retardant 4” and is derived from woven glass-reinforced epoxy laminate. At its core, FR4 is composed of:

- Glass Fiber Cloth (Woven): This layer provides mechanical strength, rigidity, and dimensional stability.

- Epoxy Resin (Thermoset): This resin serves as the bonding agent, giving the material its electrical insulation properties and flame-retardant characteristics.

The combination of these components gives FR4 its characteristic stability under temperature variations and its excellent insulation capabilities. The “FR” in FR4 references its flame-retardant nature. This means the material can self-extinguish if ignited, a crucial property in electronic applications where preventing or limiting the spread of fire is paramount.

Mechanical Strength

One of the defining attributes of FR4 is its high mechanical strength. The woven glass fibers bear significant tensile loads, making FR4 panels (laminates) highly resistant to mechanical stress and deformation. This robustness is critical in assemblies where the PCB may be subjected to vibrations, shocks, or other mechanical stressors. Even with repeated handling and assembly operations such as drilling and milling, FR4 boards typically maintain structural integrity.

Electrical Insulation

A key property that makes FR4 indispensable in PCB manufacturing is its strong electrical insulation characteristics. The epoxy resin matrix provides a stable dielectric layer. This is essential because electronic components mounted on a PCB must be insulated from each other unless intentionally connected via copper traces. FR4’s insulation performance ensures that signals remain clean, crosstalk is minimized, and short circuits are prevented.

Thermal Stability

While FR4 can function well under a range of temperatures, it is especially noted for its balance between thermal performance and cost. The glass transition temperature (Tg) for most standard FR4 materials typically falls between 110°C and 140°C. Enhanced FR4 variants can go above 150°C. This thermal stability makes FR4 suitable for most consumer and industrial applications, although extremely high-temperature scenarios (e.g., automotive underhood or aerospace) may require specialized high-Tg laminates.

Flame Retardancy

As mentioned earlier, the “FR” designation indicates flame retardance. This feature means that FR4 laminates meet UL94-V0 requirements, signifying that they will self-extinguish if ignited. In industries where fire safety is crucial—such as household appliances, industrial controls, and automotive electronics—using a flame-retardant PCB material is often a requirement.

FR4 Material Datasheet

When looking at an FR4 material datasheet, you will typically find the following parameters:

- Mechanical Properties:

- Tensile Strength (often in MPa or psi)

- Flexural Strength

- Compressive Strength

- Modulus of Elasticity

- Tensile Strength (often in MPa or psi)

- Thermal Properties:

- Glass Transition Temperature (Tg)

- Coefficient of Thermal Expansion (CTE)

- Thermal Conductivity

- Maximum Operating Temperature

- Glass Transition Temperature (Tg)

- Electrical Properties:

- Dielectric Constant (Dk or εr)

- Dissipation Factor (Df)

- Dielectric Breakdown Voltage

- Volume Resistivity

- Surface Resistivity

- Dielectric Constant (Dk or εr)

- Chemical Properties:

- Water Absorption

- Resistance to Chemicals

- Water Absorption

- Flammability Rating:

- UL94-V0 classification

- UL94-V0 classification

These datasheet values provide a quantitative basis for comparing FR4 to other PCB materials. Engineers and designers rely on datasheet values to ensure that the chosen material will meet the mechanical, thermal, and electrical requirements for a given product.

FR4 Material Density

Density is a critical parameter in applications where weight or mechanical rigidity per unit mass is a concern. For many standard FR4 laminates, the density is roughly around 1.8–2.0 g/cm³. However, variations can exist based on the exact type of resin, any filler materials, and the weave style of the fiberglass cloth.

PCB Material Density kg/m³

When converting FR4 density to kg/m³, you multiply the gram per cubic centimeter (g/cm³) value by 1,000. For example, if FR4 has a density of 1.8 g/cm³, that translates to 1,800 kg/m³. If it is 2.0 g/cm³, that translates to 2,000 kg/m³. This conversion is necessary in some engineering calculations that require standardized SI units.

Because different suppliers have slight variations in resin composition and glass reinforcement, the PCB material density kg/m³ can range in practice. Always consult a current FR4 datasheet for the specific value from the particular manufacturer you are considering.

PCB Material Density PDF

For those in the electronics engineering domain, obtaining a PCB material density PDF can be a convenient way to have quick access to consolidated density information. Many PCB laminate manufacturers and engineering resource websites publish PDF datasheets or reference materials. These documents can be downloaded and shared among teams, making it easy to reference densities of common PCB materials, including FR4, polyimide, Rogers laminates, and more.

When searching for such PDF documents, pay attention to:

- Publication date (to ensure the information is up-to-date).

- The source credibility (ideally from a laminate manufacturer or recognized testing/standards organization).

- The specific product code or variant of FR4, as slight differences in resin or weave style can yield different densities.

PCB Material Density Chart

A PCB material density chart typically lists different laminate materials side by side, along with their corresponding densities. Such a chart can be invaluable when selecting the best laminate for your product, especially if weight is a concern (e.g., aerospace or portable electronics). In addition to density, a good chart might include:

- Glass transition temperature (Tg)

- Dielectric constant (Dk)

- Dissipation factor (Df)

- Cost per unit area

By comparing these parameters in a single chart, engineers can more quickly narrow down which material suits their needs.

PCB Material Density Formula

While FR4 is generally sold as sheets of known thickness and composition, there are instances where you might want to calculate an estimated PCB density yourself. A simple PCB material density formula if you know the mass (m) and volume (V) is:

Density=mV\text{Density} = \frac{m}{V}Density=Vm

Where:

- mmm = mass in kilograms (kg)

- VVV = volume in cubic meters (m³)

Translating this to typical PCB laminate dimensions:

- Measure the mass of a specific laminate sample (weigh it accurately on a scale).

- Measure its dimensions (length, width, thickness) to determine volume.

- Plug those values into the formula.

This approach can confirm if the laminate matches the specified density in the manufacturer’s datasheet. In production environments, such verification can be helpful when dealing with large volumes or critical applications.

FR4 Material Density in kg/m³

We briefly touched on this above, but to reiterate clearly:

- Typical FR4 Density (g/cm³): ~1.8–2.0 g/cm³

- Converted to kg/m³: ~1,800–2,000 kg/m³

This range can shift slightly based on the FR4 variant. Using a sample-based measurement (as described in the PCB Material Density Formula section) is a practical way to double-check.

PCB Material Density Calculator

A PCB material density calculator can be a simple online tool that automates the process of calculating density from mass and volume, or it might allow for more advanced features such as:

- Accounting for different layers within the PCB stack-up (e.g., copper layers, solder mask, silkscreen layers, etc.).

- Using standard material densities from a built-in database.

- Generating a quick report for engineering documentation.

In highly specialized design scenarios—for instance, when developing ultra-lightweight aerospace electronics—such a calculator can be an asset. It streamlines the iterative process of selecting materials, adjusting stack-up configurations, and ensuring that you remain within weight constraints.

PCB Material Comparison Chart

A PCB material comparison chart is broader in scope than a density chart alone. It often includes a list of materials such as FR4, high-frequency laminates (e.g., Rogers), polyimide, metal-core PCBs (MCPCBs), and even flexible materials (polyimide flex circuits). Key parameters typically compared include:

- Dielectric Constant (Dk): Crucial for impedance control.

- Dissipation Factor (Df): Important for high-speed or high-frequency designs where signal losses must be minimized.

- Thermal Conductivity: This matters for heat dissipation.

- Glass Transition Temperature (Tg): Indicates thermal robustness.

- Coefficient of Thermal Expansion (CTE): A measure of dimensional stability with temperature changes.

- Density: As we’ve discussed, it is important in certain applications.

- Cost and Availability: Practical considerations for production.

By reviewing such a chart, design teams can weigh the pros and cons of each material type, ensuring the final choice aligns with both technical requirements and budgetary constraints.

FR4 Material Thickness

Standard Thicknesses

When discussing FR4 material thickness, the most common standard thicknesses are:

- 1.6 mm (0.063 inch): By far the most widespread thickness for general-purpose PCBs.

- Other available thicknesses can include 0.8 mm, 1.0 mm, 2.0 mm, and 2.4 mm. Very thin versions (e.g., 0.4 mm or 0.2 mm) exist but are less commonly used.

The selection of thickness impacts mechanical rigidity, weight, and even certain electrical characteristics like impedance. For example, some high-speed designs require specific thicknesses to achieve controlled impedance in microstrip or stripline configurations.

Influence on Density Calculations

The thickness of the FR4 laminate directly factors into your PCB material density calculations. If you measure density on a large 1.6 mm board, you will obviously end up with more mass per unit area than with a 0.8 mm board of the same composition. However, the overall density (mass per unit volume) of the material remains roughly the same. It is the thickness—and thus total volume—that changes.

FR4 Material Specification

An FR4 material specification might come in the form of an IPC standard or a manufacturer datasheet. The global electronics industry recognizes the IPC-4101 standard, which defines various requirements for base materials, including FR4. Within IPC-4101, you will find different slash sheets that detail specific sub-types of FR4, each with unique performance criteria:

- IPC-4101/21 might reference a general-purpose FR4.

- IPC-4101/24 might describe a higher Tg variant.

- And so on.

Specific aspects you will encounter in an FR4 material specification include:

- Material classification (e.g., FR4 is a woven glass-reinforced epoxy laminate).

- Thermal properties (Tg, Td, etc.).

- Electrical properties (dielectric constant, dissipation factor, breakdown voltage).

- Mechanical properties (tensile strength, modulus, etc.).

- Flammability rating (UL94-V0).

Consulting these specifications is vital to ensure the chosen material meets your product’s needs, whether it’s reliability, longevity, thermal resilience, or electrical performance.

Reiterating FR4 Material Density

While we have mentioned FR4 density in multiple sections, it is worthwhile to emphasize it once more. FR4 density is typically between 1.8 and 2.0 g/cm³ (or 1,800 to 2,000 kg/m³). This figure places FR4 in a moderate range compared to other materials. For instance, certain high-frequency laminates might have densities slightly lower or higher depending on filler content. In designs where weight minimization is paramount, every gram counts, so FR4’s density must be considered alongside its other properties.

FR4 Material Dielectric Constant

The FR4 material dielectric constant—often referred to as Dk or εr—is typically around 4.2 to 4.8 at 1 MHz. At higher frequencies (e.g., in the GHz range), the dielectric constant might shift slightly, often decreasing as frequency increases. This parameter is extremely important for high-speed digital designs and RF (radio frequency) applications because:

- Signal Integrity: The dielectric constant influences the speed of signal propagation through the PCB’s dielectric layer.

- Impedance Control: Microstrip and stripline traces use controlled impedance calculations that require accurate Dk values.

- Insertion Loss: A higher Dk can, in some contexts, correspond to greater signal loss, although the dissipation factor (Df) is also a major player here.

Advanced applications—like 5G communication systems, microwave circuits, and very high-speed data links—may need laminates with lower Dk (sometimes below 3.5) or more consistent Dk across broad frequency ranges. While FR4 is versatile and cost-effective, it is not always the best choice for extremely high-frequency applications. Nonetheless, for the majority of standard to moderately high-frequency designs, FR4 remains the most popular and cost-effective PCB laminate.

Additional Considerations for FR4-Based PCBs

Multilayer Boards

Modern electronics often require multilayer PCBs that stack multiple layers of copper and FR4 dielectric. The number of layers can range from 4 in simpler products to 40 or more in complex, high-density devices (like server boards or advanced networking equipment). FR4 is well-suited for multilayer designs because:

- It can be easily laminated multiple times while maintaining mechanical integrity.

- It supports consistent drilling and plating processes.

Reliability Testing

FR4-based PCBs must pass various reliability tests to ensure they withstand operational stresses over their lifetime. Common reliability tests include:

- Thermal Cycling: The board is exposed to repeated cycles of extreme cold and heat to check for delamination or cracking.

- Vibration and Shock Tests: These assess whether the PCB or solder joints fail under mechanical stress.

- Humidity and Salt Spray: Used in harsh environments to test corrosion resistance of copper and other metals, as well as the laminate’s moisture absorption properties.

FR4’s relatively low moisture absorption rate (~0.10% to 0.20% by weight) helps maintain stability under humid conditions, making it a popular choice in consumer electronics and industrial settings.

Environmental Compliance

With growing environmental regulations, ensuring your FR4 laminate is RoHS (Restriction of Hazardous Substances) compliant is often a requirement. Most major laminate manufacturers provide RoHS-compliant FR4 variants that eliminate or minimize restricted substances such as lead, cadmium, mercury, and certain brominated flame retardants.

Cost-Performance Balance

Despite advancements in alternative PCB materials, FR4 continues to dominate the market primarily because of its unbeatable cost-to-performance ratio. It is reasonably priced, offers robust mechanical and electrical properties, and can be processed with standard PCB manufacturing equipment. For many products, the benefits of specialized laminates (e.g., PTFE-based, polyimide) do not outweigh the significant cost increase unless specific applications demand those specialized properties (e.g., extremely high frequency, high temperature).

Working with FR4: Practical Tips

- Communicate With Your PCB Vendor: Always specify the exact laminate variant you require. If you need a certain Tg rating, let them know.

- Consider Laminates from Trusted Brands: Reputable manufacturers ensure consistent quality. Inconsistent laminate quality can lead to production defects or performance issues.

- Surface Finish Selection: While not directly related to FR4 itself, the finishing process (HASL, ENIG, OSP, etc.) can affect the final board cost, solderability, and reliability.

- Design for Manufacturability: If weight or thickness is a concern, mention any specific constraints early in the design. This proactive approach helps your PCB vendor confirm feasibility.

- Pre-Peg Considerations: In multilayer boards, you might use “pre-preg” layers (fiberglass cloth pre-impregnated with resin) to bond cores. Ensuring a consistent and proper curing process is key to overall board quality.

Conclusion

FR4 is undeniably the workhorse of the PCB industry. Its balance of mechanical strength, electrical insulation, thermal stability, and cost-effectiveness make it the go-to choice for countless applications, from household gadgets to industrial machinery and beyond. Understanding the various characteristics of FR4—from density (1.8 to 2.0 g/cm³), dielectric constant (typically around 4.2 to 4.8), and mechanical properties to thermal specifications—empowers designers and manufacturers to select the right materials for the job.

In this article, we have discussed the FR4 material properties, looked at an FR4 material datasheet, and explored why FR4 material density is crucial for certain applications. We dove into the PCB material density kg/m³ conversion, how to utilize a PCB material density pdf, and how a PCB material density chart or PCB material density formula can help. Furthermore, we explained how a PCB material density calculator can streamline your design workflow and how a PCB material comparison chart puts FR4 alongside other laminates, simplifying the selection process.

We also examined FR4 material thickness ranges, the significance of FR4 material specification (including IPC-4101 standards), and the all-important FR4 material dielectric constant for high-speed and RF designs. Armed with this knowledge, you can make more informed decisions when specifying or working with PCB board material FR4, ensuring your electronic assemblies meet the desired performance, reliability, and cost targets.