The design and implementation of brushless DC (BLDC) motors have become a cornerstone of modern automation, robotics, and electric mobility. Understanding the types of BLDC motors and controllers is crucial for engineers who want to optimize performance, efficiency, and reliability in applications ranging from drones to industrial machines. A strong foundation in motor architecture, control strategies, and pcb design principles is necessary to create effective solutions. This article provides a complete technical overview of BLDC motor types, controller categories, and their applications in real-world systems.

Why Choosing the Right BLDC Motor Matters

The selection of the right BLDC motor impacts efficiency, torque delivery, cost, and longevity. Different designs offer unique strengths:

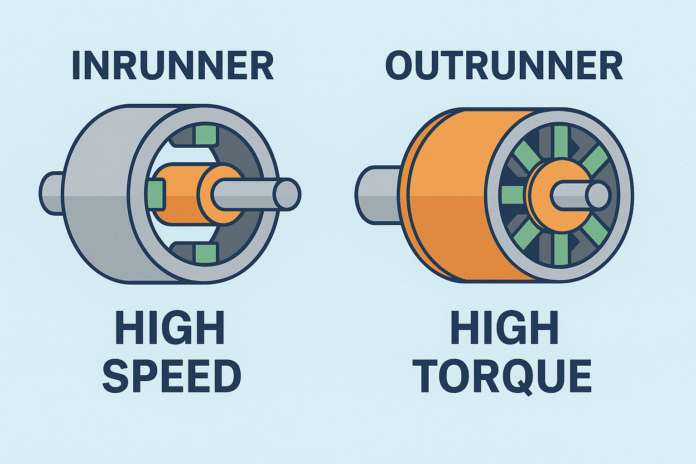

- Inrunner motors excel in high-speed applications like drones or RC vehicles.

- Outrunner motors dominate where torque is more important, such as in e-bikes or robotics.

- Connection types (star vs delta) determine current handling and protection levels.

Choosing incorrectly may lead to overheating, reduced efficiency, or shortened product lifespan. The controller type—sensor-based or sensorless—also determines responsiveness, precision, and cost.

Inrunner Motors: High-Speed, Lightweight Design

Inrunner BLDC motors have their rotors located inside the stator. Their defining features include:

- High RPM potential: Commonly reaching tens of thousands of revolutions per minute.

- Compact size and lightweight design: Perfect for drones, RC planes, and small medical devices.

- Low torque output compared to outrunners, requiring gear reduction in some cases.

Inrunners are used when speed is more critical than torque. Their simple design makes them easier to cool but limits applications requiring high mechanical force.

Outrunner Motors: High-Torque, Wider Applications

Outrunner BLDC motors have the rotor surrounding the stator, providing greater leverage and torque. Features include:

- High torque output: Often used in robotics, e-bikes, and industrial tools.

- Larger diameter than inrunners, but still lightweight relative to torque produced.

- Efficient cooling since stator remains fixed inside the rotor.

Their ability to deliver consistent torque makes them popular in electric skateboards, drones with larger propellers, and power tools.

Star (Wye) vs. Delta Connections in Three-Phase Motors

BLDC motors often use either star (wye) or delta winding connections:

- Star (Wye) connection:

- Lower current draw.

- Higher torque at lower speeds.

- Improved protection against overheating.

- Often used in industrial automation and applications requiring reliability.

- Delta connection:

- Higher current flow.

- Suited for high-speed performance.

- Less protection from overheating.

- Common in drones and lightweight electric vehicles.

The choice of connection impacts efficiency, thermal performance, and compatibility with specific controllers.

Comparing Efficiency, Current Flow, and Protection Features

- Efficiency: Star-connected motors are generally more efficient at low loads, while delta is better at high speed.

- Current Flow: Delta allows higher current through windings, enabling higher speeds.

- Protection: Star offers greater protection against overheating, making it safer for long-term use.

The trade-offs must be carefully considered in both motor design and controller matching.

Sensor-Based Controllers: Hall Sensors, Encoders, Optical Options

Sensor-based controllers rely on physical devices to detect rotor position:

- Hall sensors: Cost-effective, provide reliable commutation signals.

- Optical encoders: Deliver precise angular resolution, ideal for robotics and automation.

- Magnetic resolvers: Offer high reliability in noisy environments, often used in aerospace.

Advantages:

- Smooth startup under load.

- Accurate torque control.

- Strong performance in low-speed applications.

Disadvantages:

- Increased cost and wiring complexity.

- Sensors may fail in high-temperature or high-vibration environments.

Sensorless Controllers: Back-EMF and Cost Reduction

Sensorless controllers estimate rotor position using back electromotive force (back-EMF). Features include:

- Lower cost and simpler construction since no sensors are required.

- More compact pcb design with fewer external components.

- Higher reliability due to fewer failure points.

Challenges:

- Poor startup performance (no back-EMF at standstill).

- Limited accuracy at low speeds.

- Advanced algorithms required for precision.

Sensorless controllers are common in drones, fans, and low-cost appliances.

Key Factors in Selecting the Right Controller (Power, Speed, Cost)

When selecting a BLDC controller, engineers must consider:

- Power requirements: Does the application demand high-voltage IGBT drivers or low-voltage MOSFETs?

- Speed vs torque balance: High-speed drones may use inrunners with sensorless controllers, while EVs need outrunners with encoder feedback.

- Cost considerations: Consumer devices prioritize affordability, while industrial controllers focus on reliability and accuracy.

- PCB design constraints: Compact devices like drones require space-optimized multi-layer PCBs.

Controllers must match both electrical and mechanical requirements.

Popular Applications: Robotics, Electric Vehicles, Drones, Consumer Electronics

- Robotics: Encoders and high-precision controllers enable accurate positioning and smooth motion.

- Electric Vehicles: Outrunner motors with IGBT-based controllers provide torque, efficiency, and regenerative braking.

- Drones: Inrunner and outrunner motors with MOSFET-based controllers achieve high thrust-to-weight ratios.

- Consumer electronics: BLDC fans, pumps, and appliances use cost-effective sensorless controllers.

Each industry applies BLDC technology differently based on performance and cost needs.

Future Trends in BLDC Motor Technology

The future of BLDC motors and controllers will focus on:

- Field-Oriented Control (FOC) algorithms for smooth, efficient operation.

- Integration of AI for predictive maintenance and adaptive motor control.

- Energy harvesting to improve efficiency in portable applications.

- Miniaturization and flexible PCB design to allow controllers in wearable and embedded devices.

Advancements in semiconductor technology and magnetic materials will push performance further.

Conclusion

Understanding the types of BLDC motors and controllers is essential for modern engineering. Inrunner and outrunner designs offer different balances of speed and torque, while star and delta connections influence current flow and protection. Controllers—whether sensor-based or sensorless—determine efficiency, startup behavior, and cost. By integrating proper pcb design strategies with the right motor-controller combination, engineers can optimize systems for robotics, EVs, drones, and industrial automation. The evolution of BLDC technology continues, shaping the future of efficient motion systems across industries.