The world of electronic design has become increasingly sophisticated, demanding precise standards to ensure reliability, performance, and manufacturability. At the heart of this precision lies the IPC-2221 standard—a pivotal document issued by IPC, the global trade association for electronics manufacturing. This standard outlines essential design principles for Printed Circuit Boards (PCBs), specifically addressing sectional design requirements for rigid organic PCBs. Whether you’re a PCB designer, electronic engineer, or manufacturing specialist, understanding IPC-2221 is crucial for delivering high-quality, consistent products.

In this article, we’ll explore what the IPC-2221 standard entails, why it’s vital in modern PCB design, and how it impacts PCB board material selection and overall electronic design workflows.

What is the IPC-2221 Standard?

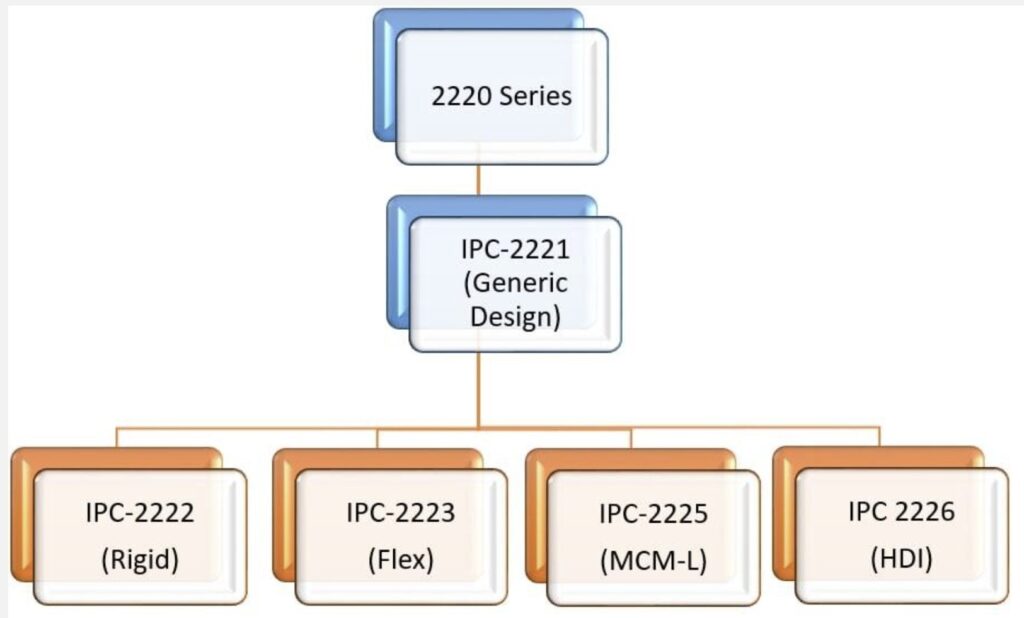

The IPC-2221 standard is a part of the IPC-2220 family of documents, which provide generic requirements for designing printed boards and other forms of component mounting or interconnecting structures. IPC-2221, specifically, is concerned with the sectional design standard for rigid organic PCBs. It offers guidance for board layout, conductor spacing, pad design, mechanical features, and fabrication allowances.

This standard serves as a blueprint for designers to create PCBs that meet specific performance classes defined by IPC:

- Class 1: General Electronic Products

- Class 2: Dedicated Service Electronic Products

- Class 3: High Reliability Electronic Products (such as medical devices or aerospace systems)

Each of these classes has different tolerances and performance expectations, and IPC-2221 helps designers meet the required targets for their specific applications.

Why IPC-2221 Matters in PCB Design

PCB design is far more than just drawing traces between components. It involves a comprehensive understanding of mechanical, thermal, and electrical constraints. The IPC-2221 standard brings uniformity and best practices to this process, offering a set of rules and guidelines that elevate the reliability and quality of PCBs.

Key benefits of following IPC-2221 in PCB design include:

- Improved Manufacturability: Manufacturers can better interpret design intent, reducing the risk of production errors.

- Enhanced Reliability: Designs created under IPC-2221 exhibit higher resilience to thermal and mechanical stresses.

- Better Communication: Having a standardized framework ensures all stakeholders—from designers to fabricators—are on the same page.

- Compliance with Global Standards: Adherence to IPC standards is often a requirement in global electronics markets, particularly for aerospace, automotive, and medical sectors.

IPC-2221 and PCB Board Material Selection

Selecting the right PCB board material is one of the most critical decisions in any PCB design. IPC-2221 provides parameters to evaluate material choices based on the intended performance class of the PCB.

Common materials addressed by the standard include:

- FR-4: A widely used fiberglass-reinforced epoxy laminate known for good electrical insulation and mechanical strength.

- Polyimide: Offers excellent thermal stability, often used in high-reliability applications.

- High-Frequency Laminates: Such as Rogers or Taconic materials, these are used in RF and microwave PCB applications.

Key considerations dictated by IPC-2221 when selecting materials:

- Dielectric Constant (Dk): Affects signal propagation speed.

- Thermal Expansion Coefficient (CTE): Mismatch between materials can lead to delamination.

- Glass Transition Temperature (Tg): Determines the material’s behavior under thermal stress.

- Moisture Absorption: Can impact impedance and reliability.

By standardizing material requirements, IPC-2221 helps designers match the material properties with the board’s functional and environmental needs.

Key Design Guidelines Under IPC-2221

Here are some of the core PCB design aspects covered under IPC-2221:

- Conductor Width and Spacing

- Determined by current-carrying capacity and impedance control.

- IPC-2221 provides tables to guide trace width based on the copper thickness and current load.

- Pad Design and Annular Rings

- Ensures robust connections between components and the PCB.

- Guidelines include minimum pad diameters and annular ring requirements based on via and hole sizes.

- Via Types and Placement

- Covers through-hole, blind, and buried vias, with design rules for each type.

- Defines acceptable aspect ratios to ensure mechanical reliability.

- Mechanical Features

- Outlines how to handle cutouts, slots, and mounting holes.

- Includes tolerances for mechanical alignment and board thickness.

- Layer Stack-up

- IPC-2221 assists in defining the ideal layer sequence for multi-layer PCBs.

- Addresses issues such as crosstalk, EMI, and power distribution.

Integration with Broader Electronic Design Process

IPC-2221 doesn’t exist in a vacuum—it supports the overall electronic design process. From schematic capture to layout and eventually manufacturing, applying IPC-2221 ensures a smoother transition between phases.

In modern electronic design, where tools like Altium Designer, KiCad, or OrCAD are used, adhering to IPC-2221 can help leverage built-in design rule checks (DRC) for automatic compliance validation. This reduces costly rework and accelerates time to market.

Furthermore, IPC-2221 helps facilitate Design for Manufacturability (DFM), Design for Testability (DFT), and Design for Assembly (DFA), all of which are key pillars in successful electronic product development.

Common Challenges and How IPC-2221 Addresses Them

Thermal Management

As devices become smaller and more powerful, thermal issues can jeopardize reliability. IPC-2221 provides thermal design parameters, including spacing rules and material selection, to aid in efficient heat dissipation.

Signal Integrity

High-speed circuits demand tight control over signal paths. IPC-2221 contributes by defining guidelines for trace length, impedance matching, and via usage to maintain signal quality.

Miniaturization

With increasing demand for compact designs, adhering to IPC-2221 helps manage high-density interconnects (HDI) and multi-layer board complexity without compromising performance.

Future-Proofing Your PCB Designs

Adopting IPC-2221 as a design baseline offers future scalability. As your product evolves or requires updates, a standards-based design makes it easier to implement changes, perform audits, or shift to alternative manufacturing partners.

IPC standards are regularly updated to reflect emerging technologies, so building your design foundation on IPC-2221 ensures alignment with current and upcoming trends in electronic design and PCB fabrication.

Conclusion

The IPC-2221 standard is a cornerstone in professional PCB design. It ties together key elements such as PCB board material selection, trace layout, mechanical tolerances, and manufacturability into a cohesive framework that promotes product reliability and performance. As electronic design continues to push boundaries in terms of speed, complexity, and miniaturization, IPC-2221 remains a guiding light for engineers striving to create robust and compliant designs.

For anyone involved in the electronic design lifecycle—from concept to manufacturing—understanding and implementing IPC-2221 is not just beneficial, it’s essential.