Transmitters play a pivotal role in the field of instrumentation and automation, allowing for accurate monitoring and control of various industrial processes. They transform physical measurements into standardized signals that can be interpreted by control systems, enabling operators to maintain efficiency, safety, and reliability. In this Blogpost, we will explore what transmitters are, how they work, the different types of transmitters used in process instrumentation, the common process variables they measure, and their applications in industrial settings.

What is a Transmitter?

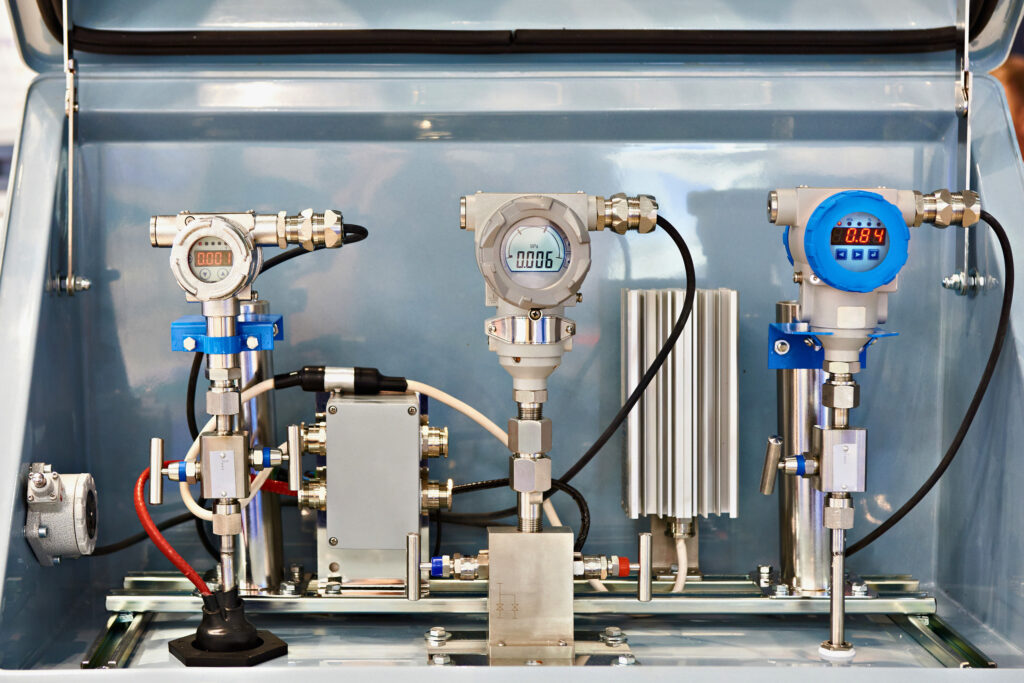

A transmitter is an electronic device that converts a physical measurement—such as pressure, temperature, flow, or level—into a standardized output signal. This signal can be transmitted to a control system, receiving device, or monitoring system for further analysis and processing. Transmitters are essential for maintaining optimal performance and safety in industrial processes, and they serve as the backbone of modern automation systems.

The output signal from a transmitter is usually in the form of an electrical or pneumatic signal, allowing it to be easily integrated into control loops and data acquisition systems. With advancements in electronic design, modern transmitters often include features that facilitate Internet of Things (IoT) connectivity, enabling remote monitoring and data analytics

How Do Transmitters Work?

Transmitters function by converting a detected physical parameter (like pressure or temperature) into an output signal. The process generally involves the following steps:

1. Sensing:

A sensor element within the transmitter detects the physical variable. Depending on the type of measurement required, this could involve a diaphragm for pressure, a thermocouple for temperature, or a float mechanism for level measurement.

2. Signal Conversion:

The sensor converts the physical variable into a raw electrical or pneumatic signal. In the case of electronic transmitters, this is usually in the form of a low-level voltage or current signal.

3. Processing:

The transmitter’s internal electronics process the raw signal to enhance accuracy, filter noise, and perform diagnostics. This step may include linearizing the output, providing temperature compensation, or enabling self-diagnostic functions.

4. Output:

Finally, the processed signal is transmitted to the control system, typically in a standardized format (like 4-20 mA current loops for analog transmitters or digital protocols for smart transmitters).

With innovative electronic design, many transmitters now incorporate advanced features that improve their functionality, from precision measurements to IoT capabilities for real-time data access.

Understanding Different Types of Transmitters in Process Instrumentation

Transmitters in process instrumentation can be classified into two main categories based on their output signals: Electronic Transmitters and Pneumatic Transmitters.

1. Electronic Transmitters

Electronic transmitters are widely used in modern industrial applications due to their accuracy and flexibility. They can further be divided into:

– Analog Transmitters:

These transmitters produce continuous output signals (commonly 4-20 mA) that represent the measured variable. They provide immediate and reliable feedback in real-time applications.

– Digital (Smart) Transmitters:

Smart transmitters incorporate advanced technology, allowing for communication via digital protocols (like HART or Fieldbus) and enabling self-diagnostics, calibration, and enhanced measurement capabilities. These devices are crucial for IoT applications, as they offer seamless integration with cloud-based monitoring systems, facilitating remote access to operational data.

2. Pneumatic Transmitters

Pneumatic transmitters operate using compressed air or gas to transmit signals. Although they are less prevalent today compared to electronic transmitters, they are still utilized in specific applications, especially in hazardous environments where electrical systems could pose risks. Pneumatic transmitters are known for their simplicity and reliability, making them suitable for certain processes and conditions.

Common Process Variables Measured by Transmitters

Transmitters are instrumental in measuring a range of process variables, including:

1- Pressure:

Used in various applications from pipelines to reactors, pressure transmitters ensure safe operation by preventing overpressure situations.

2- Temperature:

Temperature transmitters are vital in maintaining constant conditions in processes, affecting product quality and reaction rates.

3- Flow:

Flow transmitters measure the rate of fluid movement, critical for process control, efficiency, and material management.

4- Level:

Level transmitters provide information on the amount of substance within a container, ensuring inventory accuracy and preventing overflow or dry running conditions.

What are the applications of different types of transmitters?

Transmitters are used in various industries and applications, each tailored to specific measurement needs. Here’s an overview of the applications for different types of transmitters:

Integrated Temperature Transmitter:

Applications: Used in HVAC systems, chemical processing, food and beverage industries, and manufacturing processes requiring precise temperature control.

Pressure Transmitter:

Applications: Common in oil and gas, water treatment, pneumatic systems, and any application that requires monitoring pressure levels in pipes, tanks, or vessels.

Liquid-Level Transmitter:

Applications: Employed in water and wastewater treatment, chemical storage tanks, food and beverage industries, and any sector where monitoring fluid levels is critical.

Flow Transmitter:

Applications: Widely used in water distribution, oil and gas industry, chemical manufacturing, and HVAC applications to measure the flow rate of liquids and gases.

Humidity Transmitter:

Applications: Essential in HVAC systems, greenhouses, food processing, and pharmaceuticals, where maintaining specific humidity levels is crucial.

pH Transmitter:

Applications: Used in water treatment, swimming pools, food and beverage production, and chemical manufacturing for monitoring the acidity or alkalinity of solutions.

ORP Transmitter (Oxidation-Reduction Potential):

Applications: Commonly utilized in water treatment, aquaculture, and chemical processing to indicate the oxidation state of a solution.

Differential Pressure Transmitter:

Applications: Used in filter monitoring, flow measurement, and level measurement in various industrial processes to detect pressure differences across systems.

Gas Transmitter:

Applications: Employed in environmental monitoring, industrial safety, and HVAC applications to detect and measure gases like CO2, methane, and other hazardous substances.

How to choose the right transmitter for your application?

Choosing the right transmitter for your application involves several key considerations. Here’s a guide to help you make an informed decision:

1. Determine the Measurement Type:

Identify what physical property you need to measure (e.g., temperature, pressure, level, flow, humidity, pH, gas concentration).

2. Understand the Measurement Range:

Define the operating range of the parameter you intend to measure. Ensure that the transmitter’s range covers your specific requirements.

3. Consider Accuracy and Resolution:

Assess the required accuracy and resolution for your application. Higher accuracy is essential in critical processes, while less precision may be acceptable in others.

4. Select the Output Signal Type:

Choose the output type that is compatible with your control system. Common options include analog signals (like 4-20 mA) and digital signals (like Modbus or HART).

5. Environmental Conditions:

Evaluate the operating conditions such as temperature, humidity, pressure, and potential exposure to chemicals or particulates that could affect the transmitter’s performance.

6. Installation Requirements:

Consider installation factors, such as space constraints, mounting options, and the type of process connections available in your system.

7. Response Time:

Determine how quickly the sensor needs to respond to changes in the measured parameter. Faster response times are crucial in dynamic processes.

8. Calibration Needs:

Assess how often the transmitter will need calibration, and whether you have the resources to perform it in-house or if it needs to be sent to a service center.

9. Compatibility with Existing Systems:

Ensure that the chosen transmitter is compatible with your existing instrumentation and control systems.

10. Cost Considerations:

Consider your budget for initial purchase as well as long-term operational costs, including maintenance and calibration.

11. Manufacturer Support and Reliability:

Review the reputation of the manufacturer regarding quality and service support. A reliable manufacturer can significantly reduce downtime.

12. Future Scalability:

Think about potential future needs or changes in processes that might require different measurement capabilities. Choose a transmitter that allows for flexibility.

Conclusion

Transmitters are indispensable components in the world of instrumentation and automation. By understanding what transmitters are, how they work, the different types available, and their applications in measuring critical process variables, industrial professionals can enhance operational efficiency and safety across numerous applications. With advancements in electronic design and IoT integration, transmitters are evolving to offer even greater possibilities for monitoring and control in the industrial landscape. As technology continues to advance, transmitters will play an increasingly central role in the future of process automation and data-driven decision-making.