Understanding why PCBA reliability matters is essential for engineers, manufacturers, and businesses that depend on electronic products. A PCBA (Printed Circuit Board Assembly) is the backbone of nearly every device we use, from consumer electronics to medical equipment and aerospace systems. If a PCBA fails, entire systems can malfunction, resulting in safety risks, financial losses, and damage to brand reputation. Ensuring reliability requires careful component selection, manufacturing processes, and optimized pcb design that supports durability and performance. In this article, we explore the reasons PCBA reliability is critical, the components that affect it, and the techniques used to improve long-term performance.

The Importance of PCBA Reliability

Reliability is not just about making a board function during initial testing—it’s about ensuring that it continues to perform under stress, environmental changes, and long-term use.

- Consumer electronics demand longevity and reduced return rates.

- Medical devices require flawless operation to protect patient safety.

- Automotive and aerospace rely on reliability for safety-critical systems.

- Industrial automation needs PCBs that operate for years without failure.

Reliability directly impacts cost, reputation, and compliance with industry standards such as ISO, IPC, and UL.

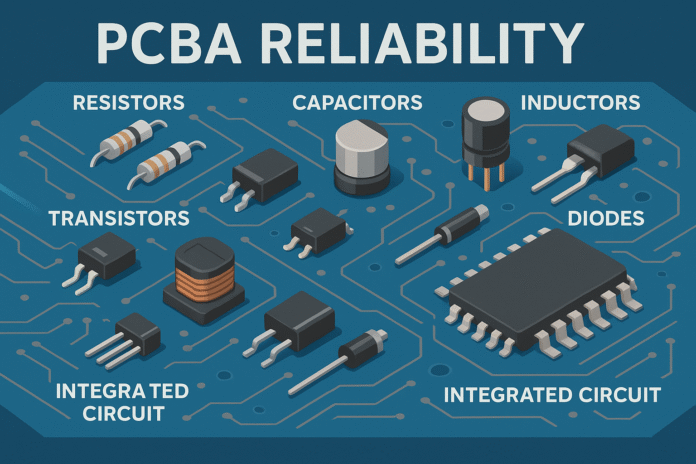

Passive Components: Resistors, Capacitors, Inductors

Passive components may seem simple, but their reliability is essential:

Resistors

Resistors dissipate heat, regulate current, and divide voltages. Poor-quality resistors may drift in value over time, leading to incorrect circuit operation. Power resistors need adequate spacing and thermal relief in pcb design to prevent overheating.

Capacitors

Capacitors filter noise, store energy, and stabilize voltage. Electrolytic capacitors are prone to drying out and failing, especially under high temperatures. Ceramic capacitors may crack under mechanical stress. Placement and mechanical support influence long-term durability.

Inductors

Inductors are used in filters and power circuits. Poor winding insulation can cause shorts. Ferrite core stability is crucial for RF and power supply reliability.

By selecting high-quality passive components, manufacturers prevent early-life failures and improve mean time between failures (MTBF).

Active Components: Transistors, Diodes, ICs

Active components amplify, switch, and process signals. Their reliability is even more critical:

Transistors

MOSFETs and BJTs control power and logic. Heat dissipation, gate oxide integrity, and switching efficiency affect long-term performance. Thermal management in pcb design helps reduce failures.

Diodes

Rectifier diodes, Schottky diodes, and Zener diodes protect and regulate circuits. Reverse breakdown failures or overheating can damage the entire PCBA. Proper derating improves reliability.

Integrated Circuits (ICs)

Microcontrollers, DSPs, and memory chips are highly sensitive to ESD, temperature, and solder joint integrity. BGA packages are especially vulnerable to hidden joint failures. X-ray inspection and conformal coating help ensure reliability in harsh environments.

High-reliability PCBA demands rigorous sourcing of active components from trusted suppliers.

Substrate Materials and Solder Types

The foundation of reliability begins with the board itself.

Substrate Materials

- FR-4 is the standard, but high-temperature grades are necessary for automotive and aerospace.

- Polyimide substrates withstand extreme thermal cycling, making them suitable for aerospace and medical devices.

- Rogers laminates offer stability for high-frequency applications.

Solder Types

- Lead-free solder is required under RoHS but tends to form brittle joints if not managed correctly.

- High-reliability solders with silver or bismuth provide better fatigue resistance.

- Flux residues must be removed to prevent corrosion and electrical leakage.

Both materials and solder impact thermal cycling endurance, vibration resistance, and long-term conductivity.

Connectors and Interconnects

Connectors are common points of failure if not designed correctly.

- Board-to-board connectors must handle repeated insertions without degradation.

- Edge connectors require plating thickness optimization for wear resistance.

- High-speed connectors need impedance-controlled layouts to avoid signal loss.

- Wire-to-board connectors face mechanical stress and require strain relief.

Proper connector placement, reinforcement, and plating selection significantly enhance PCBA reliability.

Mounting Techniques: Surface Mount vs. Through-Hole

Mounting techniques impact both electrical and mechanical strength.

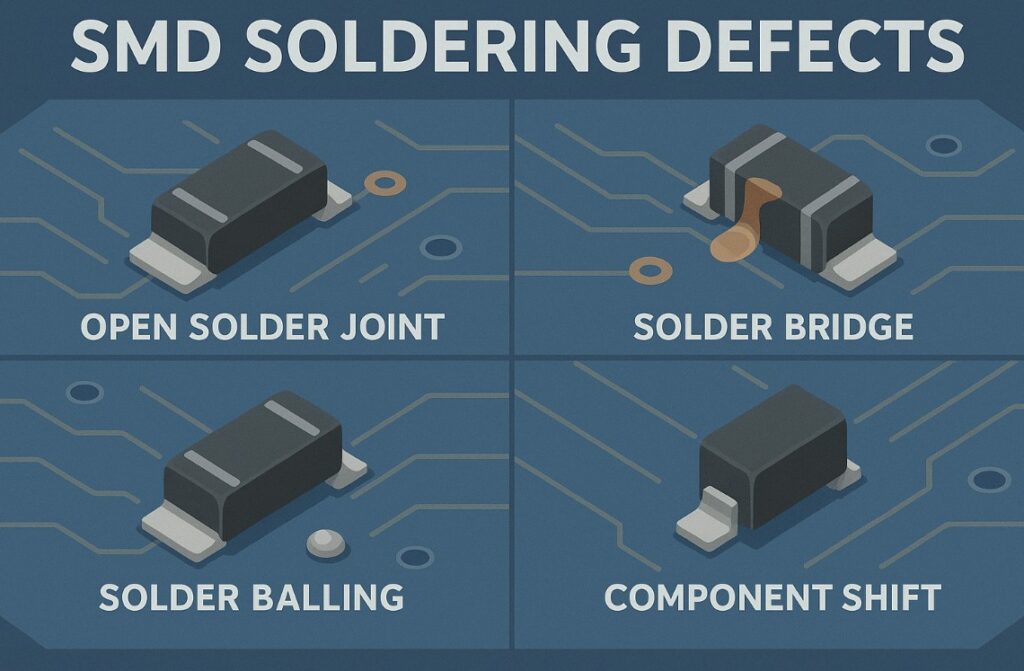

Surface Mount Technology (SMT)

- Enables miniaturization and high-density assembly.

- Vulnerable to solder joint fatigue under vibration and thermal cycling.

- Requires careful thermal relief design for power devices.

Through-Hole Technology (THT)

- Provides stronger mechanical bonds.

- Ideal for connectors, transformers, and power semiconductors.

- Takes more board space but improves durability.

Mixed Assembly

Many boards use both SMT and THT. For example, automotive ECUs use SMT for ICs but through-hole for high-current connectors. Mixed assembly balances miniaturization with robustness.

Environmental Factors Affecting PCBA Reliability

PCBA reliability must account for environmental stresses:

- Temperature fluctuations cause expansion and contraction, stressing solder joints.

- Humidity can lead to corrosion and leakage currents.

- Dust and contamination interfere with signal integrity.

- Vibration and shock impact connectors and heavy components.

Protective coatings, potting compounds, and ruggedized designs extend lifespan under harsh conditions.

Inspection and Testing for Reliability

Testing identifies potential failures before boards reach customers.

- AOI (Automated Optical Inspection) detects missing and misaligned components.

- X-ray inspection checks hidden solder joints under BGAs.

- ICT (In-Circuit Testing) validates electrical functionality.

- Burn-in testing stresses boards to detect early failures.

- Environmental testing simulates humidity, vibration, and thermal cycles.

High-reliability applications may require 100% functional testing, while consumer devices balance between cost and quality.

The Role of PCB Design in Long-Term Reliability

Strong pcb design practices prevent reliability issues:

- Proper trace width ensures current handling without overheating.

- Controlled impedance maintains high-speed signal quality.

- Thermal vias and copper pours help dissipate heat.

- Component spacing prevents arcing and improves manufacturability.

- Isolation between analog and digital domains prevents noise interference.

Design for manufacturability (DFM) ensures smoother production and reduces defects.

Industry-Specific Reliability Requirements

Different industries demand different reliability standards:

- Automotive: IPC-A-610 Class 3, AEC-Q200 qualification for components.

- Medical: ISO 13485 and FDA compliance for safety.

- Aerospace: DO-254 and NASA standards for mission-critical electronics.

- Telecommunications: High uptime requirements, thermal management for 24/7 operation.

Meeting these requirements ensures compliance and customer confidence.

Future Trends in PCBA Reliability

As electronics evolve, reliability challenges grow:

- 5G devices require low-loss substrates and precision interconnects.

- Electric vehicles push power electronics to higher currents and voltages.

- IoT devices need miniaturized boards that withstand long lifespans in the field.

- AI-driven predictive maintenance will monitor boards in real time for failure prediction.

Future PCBA reliability will depend on integrating advanced materials, smarter inspection, and adaptive design.

Conclusion

Understanding why PCBA reliability matters is critical for building durable, safe, and efficient electronic systems. Reliability is shaped by passive and active components, substrate materials, connectors, soldering techniques, and environmental protections. Effective pcb design ensures proper thermal management, signal integrity, and manufacturability. By prioritizing reliability, engineers not only extend product lifetimes but also protect brand reputation and end-user safety. As electronics become more advanced and mission-critical, PCBA reliability will remain a defining factor in successful product development.