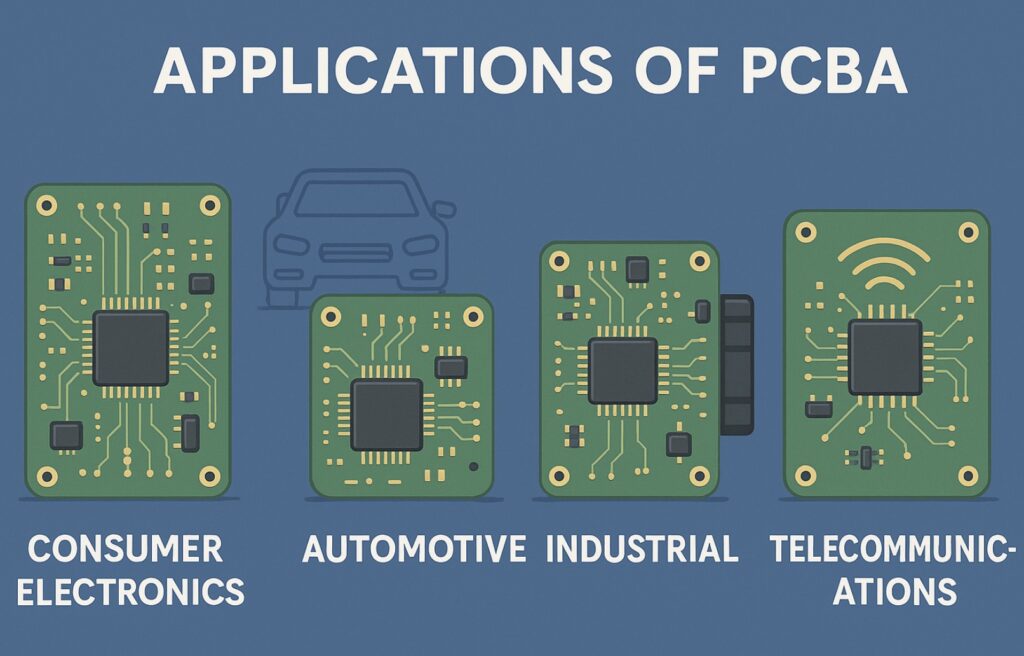

Understanding the applications of PCBA (Printed Circuit Board Assembly) is essential for engineers, businesses, and innovators across industries. PCBA is the backbone of electronic devices, transforming raw circuit boards into functional systems by assembling active and passive components, connectors, and integrated circuits. From smartphones to spacecraft, PCBAs play a vital role in enabling reliability, connectivity, and intelligence. Successful deployment requires not only efficient assembly but also careful pcb design to ensure performance, durability, and cost-effectiveness. This article explores the most important applications of PCBA, highlighting industry-specific use cases and future trends.

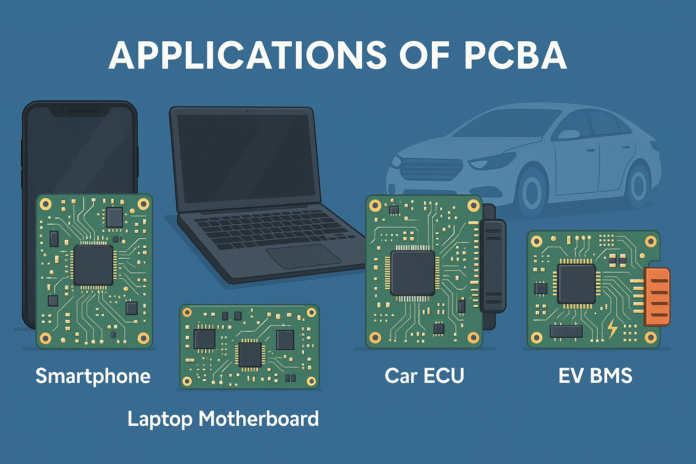

PCBA in Consumer Electronics

Consumer electronics represent the most widespread application of PCBA. Every household and personal device—from smartphones to smart TVs—relies on circuit assemblies.

- Smartphones and tablets: High-density multi-layer PCBAs integrate processors, memory, sensors, and communication modules. Miniaturized pcb design allows for compact yet powerful devices.

- Laptops and desktops: Complex motherboard assemblies include CPUs, GPUs, and RAM slots with tight thermal and electrical requirements.

- Wearable devices: Smartwatches and fitness trackers use flexible PCBAs to achieve lightweight and compact designs.

- Home appliances: Washing machines, refrigerators, and smart thermostats employ PCBAs for control, automation, and connectivity.

The consumer electronics sector demands high-volume, low-cost manufacturing with strong emphasis on miniaturization and durability.

Automotive Systems and Control Units

Modern vehicles are highly dependent on electronics, and PCBAs play a central role in safety, performance, and efficiency.

- Engine Control Units (ECUs): PCBAs regulate fuel injection, ignition timing, and emissions control.

- Infotainment systems: Advanced displays, navigation, and connectivity modules run on high-speed PCBA platforms.

- ADAS (Advanced Driver Assistance Systems): Radar, lidar, and camera modules rely on high-reliability PCBAs with real-time processing.

- Electric vehicles (EVs): Battery management systems, power inverters, and charging modules depend on multilayer boards with excellent thermal management.

Automotive-grade PCBAs must withstand vibration, high temperatures, and long lifespans, requiring strict design and testing standards such as IPC Class 3 and AEC-Q100 qualifications.

PCBA in Medical Devices (e.g., MRI, Pacemakers)

Reliability and accuracy are vital in medical applications where PCBA failures can endanger lives.

- Pacemakers and implants: Require miniaturized, biocompatible PCBAs with extreme reliability. Flexible and rigid-flex designs are common.

- MRI and CT scanners: Use large-scale PCBAs to manage imaging sensors, high-speed data acquisition, and real-time processing.

- Portable devices: Blood glucose monitors, digital thermometers, and wearable biosensors rely on compact PCBAs with wireless connectivity.

- Surgical equipment: Robotics-assisted surgical devices use advanced PCBAs for motor control, precision sensing, and closed-loop feedback.

Medical PCBAs are manufactured under strict ISO 13485 quality control, with rigorous testing for safety and performance.

Industrial Equipment and Automation Systems

Factories and automation systems depend on PCBA-powered electronics to control machinery, sensors, and robotics.

- Programmable logic controllers (PLCs): Rugged PCBAs control industrial machines and assembly lines.

- Motor drives and controllers: High-current boards regulate speed and torque in manufacturing equipment.

- Sensors and IoT gateways: Industrial sensors connect through PCBAs to collect and transmit data.

- Robotics systems: Robot arms and autonomous guided vehicles (AGVs) use PCBAs for navigation and precision actuation.

Industrial PCBAs must endure extreme environments, including temperature swings, dust, humidity, and electromagnetic interference. Conformal coatings and industrial-grade materials enhance reliability.

Aerospace and Defense Applications

Aerospace and defense applications require PCBAs that meet the highest standards of reliability, often operating in extreme conditions.

- Avionics: Flight control systems, navigation units, and communication systems use multilayer PCBAs designed for high-frequency performance.

- Defense systems: Radar, missile guidance, and secure communication equipment rely on ruggedized PCBA assemblies.

- Satellites: Space-grade PCBAs must resist radiation, vacuum, and extreme temperatures while maintaining flawless performance.

- Unmanned Aerial Vehicles (UAVs): Lightweight PCBAs control propulsion, sensors, and communication systems.

Military and aerospace PCBAs are often designed with redundant circuits, radiation-hardened components, and specialized high-reliability materials such as polyimide substrates.

Emerging Trends: IoT and Wearable Devices

The growth of the Internet of Things (IoT) has created new applications for PCBAs.

- Smart home devices: PCBAs power connected lighting, thermostats, and security systems.

- Wearables: Fitness trackers, smart clothing, and medical monitoring devices depend on flexible PCBAs.

- Industrial IoT (IIoT): PCBAs enable smart factories by connecting sensors, controllers, and cloud systems.

- Edge computing devices: Compact PCBA modules handle local processing for AI and machine learning tasks.

IoT trends demand low-power, high-density pcb design combined with wireless connectivity, ensuring seamless integration into daily life.

The Role of PCB Design in Application Success

No matter the application, the success of PCBA starts with effective pcb design. Key design strategies include:

- Thermal management: Using copper pours, vias, and heat sinks for cooling.

- Signal integrity: Controlled impedance traces for high-speed circuits.

- Component placement: Optimized layouts for automated assembly and testing.

- Design for manufacturability (DFM): Ensuring cost-effective production without compromising quality.

- Design for testability (DFT): Incorporating test points and layouts that allow AOI and ICT verification.

By considering application-specific requirements during design, engineers ensure better performance and reliability across industries.

Inspection and Testing for Application-Specific Reliability

Each industry imposes unique testing requirements:

- Consumer electronics: Functional and stress testing to prevent early returns.

- Automotive: Thermal cycling, vibration, and burn-in testing for long-term reliability.

- Medical: Biocompatibility and FDA regulatory testing.

- Aerospace: Environmental simulation, radiation resistance, and mission-specific verification.

Testing ensures that PCBAs perform flawlessly in their intended environments.

Future Outlook of PCBA Applications

As industries evolve, so will PCBA applications:

- 5G and beyond: High-frequency laminates will enable faster communication systems.

- Electric vehicles: PCBA innovations will push energy density and efficiency.

- Wearables and healthcare: Flexible, stretchable PCBAs will expand capabilities.

- AI-driven inspection: Machine learning will enhance quality control and predictive maintenance.

- Sustainability: Eco-friendly materials and recycling processes will improve environmental impact.

The future of PCBA will be defined by miniaturization, intelligence, and resilience.

Conclusion

The applications of PCBA span across every modern industry, powering devices that define our daily lives and critical systems that ensure safety and progress. From consumer electronics and automotive systems to aerospace and IoT, PCBA is the foundation of innovation. By integrating strong pcb design, advanced manufacturing techniques, and rigorous testing, engineers ensure reliability and performance. As technology advances, PCBAs will continue to evolve, driving the next generation of electronic systems in healthcare, mobility, defense, and beyond.