Introduction to Flexible PCBs

In the modern electronic landscape, the push for more compact, efficient, and flexible devices has resulted in significant developments in printed circuit board (PCB) technology. Flexible PCBs, commonly referred to as flex PCBs, embody adaptability, allowing for innovative designs that traditional rigid PCBs cannot achieve. As industries demand lighter, thinner, and more complex circuit solutions, understanding the materials used in flexible PCB fabrication is crucial for designers and engineers alike.

This article delves into the materials that underpin flexible PCBs, explores the best options available, and focuses on how they enhance PCB design, fabrication, and manufacturing processes.

What is a Flexible PCB?

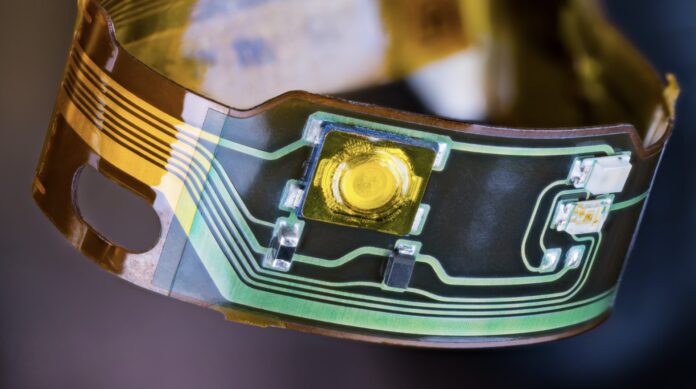

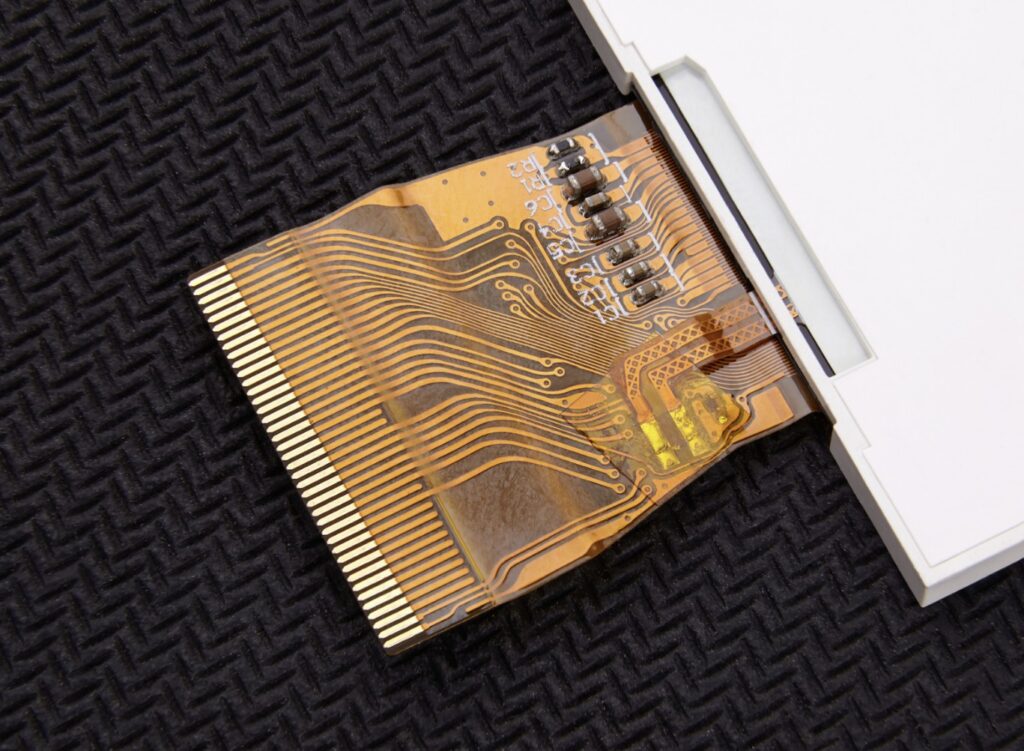

Flexible PCBs are circuit boards made of flexible substrates, allowing them to bend, twist, and conform to various shapes while still maintaining their electrical conductivity. They are used in a wide variety of applications, from mobile phones and laptops to medical devices and wearable technology. The unique properties of flexible PCBs enable them to reduce space and weight significantly while improving the performance of electronic devices.

Which Material is Used for Flexible PCB?

Flexible PCBs are primarily constructed using three types of materials: substrates, conductors, and encapsulation layers. Each material plays a pivotal role in the functionality and durability of the PCB.

1. Substrate Materials

The substrate forms the backbone of a flexible PCB and is a key determinant of its overall properties. The following materials are commonly used:

- Polyimide (PI):

- Polyimide is the most widely used substrate for flexible PCBs due to its excellent thermal stability, mechanical strength, and chemical resistance. It can endure high temperatures during soldering and assembly processes, making it ideal for various applications.

- Polyester (PET):

- Polyester substrates are less expensive than polyimide but have lower thermal stability. They are suitable for applications where bending is minimal and cost is a primary concern. However, PET is generally limited to less demanding applications compared to PI.

- Other Materials:

- Emerging materials such as polyvinyl fluoride (PVF) and thermoplastic elastomers are also being explored for specialized applications due to their unique properties.

2. Conductor Materials

The choice of conductor material affects the electrical performance and reliability of the flexible PCB. The most common conductor materials include:

- Copper:

- Copper is the standard conductor material used in flexible PCBs due to its excellent conductivity and formability. It can be applied in various thicknesses depending on the application requirements. Copper can be plated or etched to create intricate circuit patterns.

- Silver:

- Silver is sometimes used for specialized high-frequency applications due to its superior conductivity. However, it is more expensive, which limits its application in general consumer electronics.

- Gold:

- Gold is used for specific high-reliability applications, particularly in connectors and bonding pads. It provides excellent corrosion resistance and conductivity.

3. Encapsulation Layers

The encapsulation material protects the conductive and substrate layers from environmental factors. Common encapsulation materials include:

- Silicone:

- Silicone provides excellent flexibility and protection against moisture and temperature fluctuations. It is widely used in applications subject to thermal cycling and humidity.

- Epoxy:

- Epoxy resins are popular for their strong adhesion properties and chemical resistance. They are often used for potting and encapsulating PCBs to enhance durability.

- Polyurethane:

- Polyurethane is used for its flexibility and resilience, making it ideal for applications that may experience physical stress or wear over time.

Best Flexible PCB Material

Identifying the best flexible PCB material often depends on the specific requirements of the application. However, polyimide (PI) substrates stand out as the most preferred choice due to their superior properties:

- High Thermal Resistance:

- Polyimide can withstand temperatures ranging from -269°C to 400°C, which is essential for industries like aerospace and automotive where high performance is crucial.

- Flexibility and Durability:

- The inherent flexibility of polyimide allows it to be bent without breaking, essential for compact device designs. It also boasts excellent resistance to moisture, chemicals, and radiation.

- Electrical Performance:

- Polyimide substrates provide excellent dielectric properties, which enhance the signal integrity of high-speed and high-frequency circuits.

- Cost Consideration:

- While PI is more expensive than PET and other materials, its performance benefits often justify the cost in critical applications where reliability and durability are essential.

Factors Influencing Material Selection

When selecting flexible PCB materials, several factors come into play:

- Application Requirements:

- Different applications may dictate specific needs in terms of thermal resistance, mechanical stress, and flexibility.

- Manufacturing Process:

- The choice of materials must align with the chosen PCB fabrication techniques, which can include additive, subtractive, or hybrid processes.

- Cost Constraints:

- Budget considerations often influence material choice, particularly in consumer electronics where mass production is required.

- Environmental Factors:

- Consideration for environmental impacts and regulatory standards may limit material selections, especially for industries focused on sustainability.

Advances in Flexible PCB Material Technology

The world of flexible PCBs is continuously evolving, with ongoing research and development aimed at introducing new materials and improving existing ones. Some of the latest trends include:

1. Smart Materials

Innovations in smart materials, such as shape-memory alloys and piezoelectric materials, are being explored for applications that require adaptability or responsive behavior. These materials can provide enhanced functionality in flexible electronics, such as self-healing or energy-harvesting capabilities.

2. Printed Electronics

Printed electronics technology has led to the development of flexible PCBs using additive manufacturing techniques. This approach allows for the direct printing of conductive inks and functional materials onto flexible substrates, thereby reducing waste and potentially lowering costs.

3. Biodegradable Materials

As sustainability becomes increasingly important, research is being focused on developing biodegradable substrates and conductors for flexible PCBs. These green alternatives could help mitigate the environmental impact of electronic waste.

Importance of Flexible PCB Material in PCB Manufacturing

The choice of flexible PCB materials significantly impacts the overall PCB manufacturing process:

1. Design Flexibility

Flexible materials allow for more innovative PCB design approaches. Designers can create compact assemblies that fit into tight spaces or intricate shapes without compromising performance.

2. Manufacturing Efficiency

Advanced manufacturing processes can take advantage of the flexibility of the materials utilized, resulting in streamlined production and reduced assembly times. Flex PCBs can often be integrated more easily into devices compared to traditional rigid boards.

3. Improved Product Reliability

Quality materials lead to more reliable products. Flexible PCBs are less prone to cracking and other mechanical failures during device operation, particularly in dynamic applications like automotive systems.

Challenges in Flexible PCB Material Selection

Although flexible PCBs offer numerous advantages, there are challenges associated with material selection:

1. Cost Considerations

While flexible PCBs can lead to cost savings in certain applications, the raw materials, particularly polyimide, can be more expensive than traditional rigid PCB materials. This cost factor must be balanced against the benefits of using flexible technology.

2. Manufacturing Complexity

Flexible PCBs can introduce complexities in the manufacturing process. For instance, aligning layers accurately is crucial, requiring precise fabrication techniques that can increase production lead times.

3. Mechanical Limitations

While materials like polyimide offer excellent flexibility and strength, designs must carefully consider mechanical stress points and potential fatigue failure over time in high-stress applications.

Conclusion

Flexible PCB materials are at the forefront of modern electronics, enabling groundbreaking innovations across various industries. Understanding these materials’ properties, benefits, and limitations is essential for anyone involved in PCB design, fabrication, and manufacturing. As technology advances, the field of flexible PCBs will likely continue to grow, offering even more possibilities for creating efficient and reliable electronic devices.

By prioritizing the right flexible PCB materials, designers and manufacturers can contribute to the development of next-generation electronic products that meet the evolving needs of consumers and businesses.