In the fast-paced world of technology and innovation, time-to-market is critical. Electronic prototyping services have emerged as a cornerstone for companies seeking to develop high-quality products efficiently. These services provide a structured approach to validating designs, identifying potential issues, and refining functionality before mass production. In this article, we will explore the various aspects of electronic prototyping, its benefits, and its role in streamlining product development.

What Are Electronic Prototyping Services?

Electronic prototyping services involve the creation of working models or prototypes of electronic devices. These prototypes serve as tangible representations of a product’s design, allowing engineers and developers to test and refine their ideas. Prototyping can range from simple breadboard assemblies to fully functional, production-ready units. These services often include design consultation, circuit layout, component sourcing, and prototype assembly.

The Role of Prototyping in Product Development

Prototyping bridges the gap between conceptual design and production. It enables:

- Design Validation: Prototypes allow designers to verify that the initial concept meets functional and performance requirements.

- Risk Reduction: Testing a prototype helps identify design flaws or compatibility issues early in the development process, reducing costly revisions later.

- Stakeholder Communication: A physical prototype communicates ideas more effectively to stakeholders, including investors, team members, and customers.

- Iterative Improvement: Prototypes support iterative design, enabling continuous improvements until the product achieves the desired performance and reliability.

Types of Electronic Prototypes

There are several types of prototypes, each serving a specific purpose during product development:

Proof-of-Concept (PoC):

Demonstrates the feasibility of a particular idea or technology without focusing on aesthetics or detailed functionality.

Functional Prototypes:

Includes all operational features of the final product, focusing on performance rather than appearance.

Visual Prototypes:

Focuses on the physical appearance and ergonomics of the product without operational functionality.

Production-Ready Prototypes:

Combines functionality and aesthetics, closely resembling the final product for pre-production testing.

Benefits of Electronic Prototyping Services

- Faster Development Cycles: Prototyping accelerates the product development timeline by enabling rapid testing and feedback loops.

- Cost Savings: Early identification of design flaws prevents expensive modifications during the production phase.

- Improved Design Quality: Iterative prototyping ensures that the final design is optimized for performance, reliability, and usability.

- Enhanced Collaboration: Prototypes facilitate communication between designers, engineers, and manufacturers, ensuring alignment across teams.

- Market Readiness: A refined prototype can be used for consumer testing, regulatory approval, and marketing, reducing time-to-market.

Steps in the Electronic Prototyping Process

- Concept Development: This stage involves brainstorming, research, and creating initial sketches or digital models of the product.

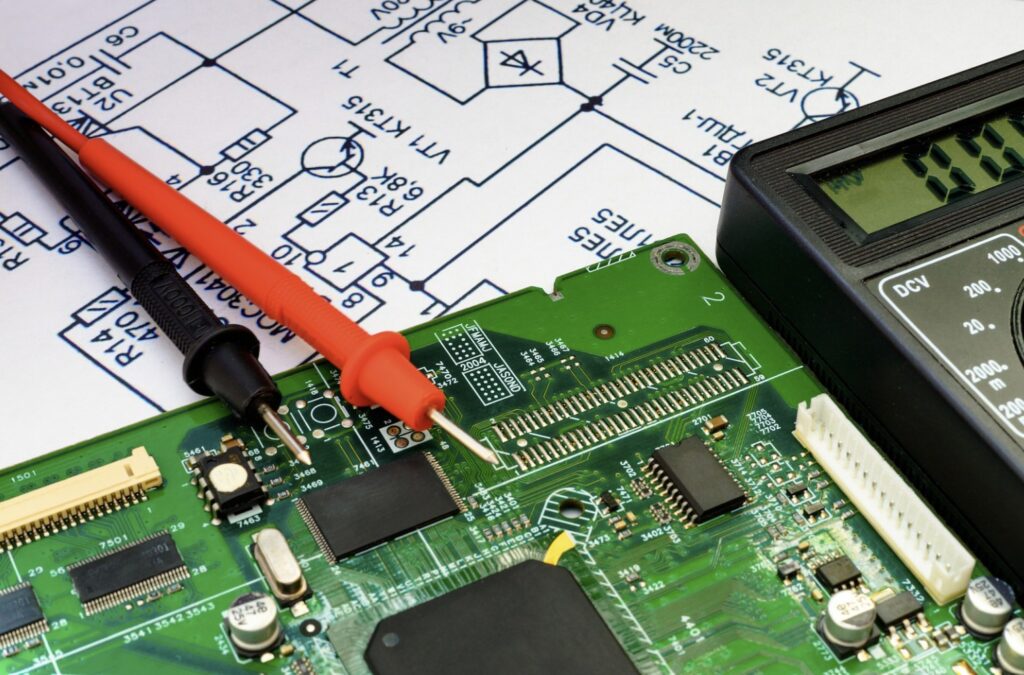

- Schematic Design: Engineers develop a circuit diagram to define the electronic functionality.

- PCB Layout: The schematic is translated into a physical layout for the printed circuit board (PCB), which forms the backbone of the electronic prototype.

- Component Selection: Choosing appropriate components based on performance, availability, and cost.

- Prototype Assembly: Assembling the components and PCBs to create the prototype.

- Testing and Validation: The prototype undergoes rigorous testing to identify and resolve any design issues.

- Iteration: Based on feedback, the prototype is refined through multiple iterations until the final design is achieved.

Challenges in Electronic Prototyping

- Cost Constraints: Prototyping can be expensive, especially for advanced designs requiring custom components or specialized equipment.

- Time Pressure: Balancing thorough testing with tight deadlines is often challenging.

- Component Availability: Supply chain issues can delay the prototyping process.

- Design Complexity: As products become more advanced, prototyping requires sophisticated tools and expertise.

How to Choose the Right Prototyping Service Provider

Selecting a reliable electronic prototyping service provider is critical for successful product development. Consider the following factors:

- Expertise: Ensure the provider has experience in your industry and understands your specific requirements.

- Capabilities: Look for providers with advanced tools and facilities for PCB design, assembly, and testing.

- Turnaround Time: Evaluate their ability to deliver prototypes within your desired timeline.

- Quality Assurance: Check for certifications and quality control measures that ensure high standards.

- Customer Support: Reliable communication and support are essential for a smooth prototyping process.

Emerging Trends in Electronic Prototyping

- Rapid Prototyping: Techniques like 3D printing and automated PCB assembly are shortening development cycles.

- IoT Integration: Prototypes are increasingly incorporating IoT features, enabling smart and connected products.

- Miniaturization: Advances in technology are enabling smaller, more compact prototypes for wearable devices and other applications.

- Sustainability: Eco-friendly materials and energy-efficient designs are becoming a priority in prototyping.

Conclusion

Electronic prototyping services are an indispensable part of modern product development, enabling companies to transform innovative ideas into market-ready products efficiently. By leveraging these services, businesses can reduce risks, save costs, and deliver high-quality products that meet consumer demands. As technology continues to evolve, the role of prototyping will only become more critical, driving innovation and success in the competitive electronics industry.